Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

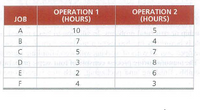

| Six jobs are to be processed through a two-step operation. The first operation involves sanding, and the second involves painting. Processing times are as follows: Determine a sequence that will minimize the total completion time for these jobs. Illustrate graphically. |

Transcribed Image Text:OPERATION 1

OPERATION 2

JOB

(HOURS)

(HOURS)

A

10

4

C

5

D el 3

8

E

6

F

4

3

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps with 1 images

Knowledge Booster

Similar questions

- Job Processing Time Due Date (Di) 1 22 35 2 18 40 3 20 32 4 15 28 5 17 30 Compute the average flowtime and Average tardiness in the following sequences: SPT/SOT and EDD What sequencing rule do you recommend and why?arrow_forwardneed correct and complete answer this timearrow_forwardRon Satterfield's excavation company uses both Ganit scheduling charts and Gantt load charts. Today, which is the end of day 7, Ron is reviewing the Gantt chart depicting these schedules: Job #151 was scheduled to begin on day 3 and to take 5 days. It got started on time and is 1 day ahead of schedule. Job #177 was scheduled to begin on day 1 and take 4 days. It is currently on time. Job #179 was scheduled to start on day 6 and take 2 days. It actually got started on day 5 and is progressing according to plan. Job #211 was scheduled to begin on day 5, but missing equipment delayed it until day 6. It is progressing as expected and should take 3 days. Job #215 was scheduled to begin on day 5 and take 5 days. It got started on time but has since fallen behind 1 day. This exercise contains only part a a) Add the actual progress to the Gantt schedule shown on the right (on which the planned timings have been already plotted as blue lines). Using the line drawing tool, plot the actual…arrow_forward

- Using the FCFS rule for scheduling, the sequence is 1-2-3. For the schedule developed using the FCFS rule, the total length of time taken to complete the three suits (including delivery) = hours (enter your response as a whole number). Sunny Park Tailors has been asked to make three different types of wedding suits for separate customers. The table below highlights the time taken in hours for cutting and sewing (process 1) and delivery (process 2) of each of the suits. Times Taken for Different Activities (hours) Cut and Sew Suit 1 2 3 6 5 8 Deliver 324 2 4 Assume that orders for suits have been listed in the above table in the order in which they were received.arrow_forwardUsing the FCFS rule for scheduling, the sequence is 1-2-3 For the schedule developed using the FCFS rule, the total length of time taken to complete the three suits (including delivery)= 22 hours (enter your response as a whole number). Using Johnson's rule for 2-machine scheduling, the sequence is 3-2-1 For the schedule developed using the Johnson's rule, the total length of time taken to complete the three suits (including delivery)= hours (enter your response as a whole number). D Sunny Park Tailors has been asked to make three different types of wedding suits for separate customers. The table below highlights the time taken in hours for cutting and sewing (process 1) and delivery (process 2) of each of the suits Times Taken for Different Activities (hours) Cut and Sew Suit 1 2 3 5 Deliver 2 3 6 D Assume that orders for suits have been listed in the above table in the order in which they were received.arrow_forwardUse Johnson's rule to determine the optimal processing sequence for the jobs listed in the following table. JOB F has the ABCDEFG Processing Time (mins) ST1 30 8 10 18 5 15 14 ST2 12 16 9 7 4 5 20 Please write the optimal processing sequence for the six jobs:arrow_forward

- In a job shop, there are four machines: a miller, a planer, a drill, and a packager. The natural process times (in minutes) for each of the machines are: 8, 8, 10, and 13, respectively. The critical WIP of the system, if the four machines are connected in the order given is:arrow_forwardKamauf Custom Glass, Inc., manufactures custom windows primarily for homes and churches. Small repair jobsmay take a few hours, but larger jobs may take hundreds ofhours. How to schedule the jobs is a continuing issue. The schedulerhas decided to see what insight can be gained by examiningsome common sequencing rules, namely FCFS, EDD, SPT, andLPT, on the criteria of average completion (flow) time, averagelateness, and average number of jobs in the system. Her sampleis the six jobs on the scheduler's desk Monday morning. Assumethat all jobs on the scheduler's desk arrived today (day 100, whichis a workday) in the order shown below. The estimated times tocomplete the jobs and their due dates are noted. a) Sequence the jobs according to the following decision rules:FCFS, EDD, SPT, and LPT.b) For the FCFS sequence, compute the average completion(flow) t ime, average lateness, and average number of…arrow_forwardJob times which includes processing and set up times are shown below: Job Job Time (bs) Due Date (bs) 15 24 20 8 6 A > B C D 12 6 14 3 7 B Using FCFS, determine the average flowtimearrow_forward

- Priority rules. Job times (including processing and setup) are shown in the following table for five jobs waiting to be processed at a work center.Job Job Time (hours) Due Date (hours)a 12 15b 6 24c 14 20d 3 8e 7 6Determine the processing sequence that would result from each of these priority rules:a. SPT b. EDDarrow_forwardPlease correctarrow_forwardA defense contractor in Dallas has six jobs awaiting processing. Processing time and due dates are given in the table. Assume that jobs arrive in the order shown. Compare the average completion time, utilization, average jobs in the system and average job lateness of the following scheduling rules. Start date is day 1. a) SPT: shortest processing time and b) EDD: earliest due datearrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.