Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

Transcribed Image Text:Normal

Time

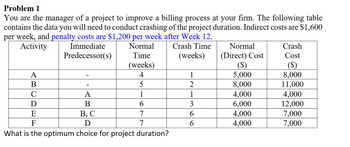

Problem 1

You are the manager of a project to improve a billing process at your firm. The following table

contains the data you will need to conduct crashing of the project duration. Indirect costs are $1,600

per week, and penalty costs are $1,200 per week after Week 12.

Activity

Immediate

Predecessor(s)

Crash Time

(weeks)

Normal

(Direct) Cost

Crash

Cost

(weeks)

($)

($)

A

4

1

5,000

8,000

B

5

2

8,000

11,000

C

A

1

1

4,000

4,000

Ꭰ

B

6

3

6,000

12,000

E

B, C

7

6

4,000

7,000

F

Ꭰ

7

6

4,000

7,000

What is the optimum choice for project duration?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps

Knowledge Booster

Similar questions

- Problem 4 Draw the network diagram from the following information. Create a data sheet for ES, EF, LS, LF, TF, FF, INTF and Independent Float. Find the critical path and critical activities. CIV 417/CPM THE NETWORK DIAGRAM Activity Duration (days) Activity Description 1-2 Relocation of Boundaries-Cleaning 1 2-3 2 Construction of Field Office 2-4 5 Delivery of Materials 2-5 2 Staking and batter boards 3-5 Digging/excavation 4-5 10 Cutting and assembling of steel reinforcement 4-7 Dummy 3-6 12 Making of forms and door jambs 5-6 Positioning Steel Reinforcement 5-7 Forms and Scaffoldings 5-8 8 Electrical, plumbing and water pipe connections 6-8 Dummy 6-9 Pouring of footings and columns 2 7-8 1 Removal of forms CIV 417/CPM 95arrow_forwardA company must perform a maintenance project consisting of seven activities. The activities, their predecessors, and their respective time estimates are presented below: Activity Break down both machines Clean machine 1 Clean machine 2 Re-set machine 1 Re-set machine 2 Re-calibrate both machines. Final test Designation A B с Using CPM, which activities have slack in this project? D E F G Immediate Predecessor None A A B с D and E F Time in Days 3 3 3 4 2 1 1arrow_forward.arrow_forward

- Example 2.39 Table 2.119 provides normal and crash times as well as normal and crash costs for the activities of a project. Table 2.119 Project activity details Activity Normal Time (Weeks) Normal Cost (Lakhs) Crash Time (Weeks) 1-2 3 5 2-3 4 8 2-4 3 4 2-5 8 S 3-6 4 3 4-6 6 2 5-7 5 10 6-7 3 7 1 3 2 7 2 4 4 1 Crash Cost (Lakhs) 9 14 6 6 5 3 14 10 Project Network Analysis-1 | 141 (a) Draw the network and find the critical path. (b) Using the above information, crash or shorten the activities step by step until the shortest duration is reached. MMM, VI Sem, Mumbai Univ, 2006arrow_forwardThe following table details the tasks required for Indiana-based Frank Pianki Industries to manufacture a fully portable industrial vacuum cleaner. The times in the table are in minutes. Demand forecasts indicate a need to operate with a cycle time of 11 minutes. Fig. 1 Activity Activity Description rerormance Predecessors Time (mins) A Attach wheels to tub 5.0 B Attach motor to lid 1.6 Attach battery pack Attach safety cutoff 3.0 D 3.6 Attach filters 3.0 Fig. 2 F Attach lid to tub 2.0 A, E G Assemble 3.0 attachments H. Function test 3.7 D, F, G Final inspection Packing 2.0 J 2.0 a-b) One of the possible assignment of tasks to workstations is shown correctly in Fig. 2. The efficiency of the assembly line with 3 workstations = 99.31 % (enter your response rounded to two decimal Fig. 3 places). c) The goal is to have 100% efficiency. Is this possible? No BI d) The theoretical minimum number of workstations = (round your response up to the next whole number).arrow_forwardActivity Normal_time Crash_time Normal_cost Crash_cost Slack A 31 17 4800 6200 В 14 14 5500 5500 C 34 18 5100 6600 21 17 4500 6800 E 15 15 5300 5300 F 17 17 5300 5300 The table shows normal time, crash time, normal cost, crash cost and slack time of activities in a project. According to this table which activity must be crashed first? Assume there is only one critical path. (Only type the name of the activity, Example: A. @orsdemir. Copyrighted content. Cannot be posted.) 0ㅇ11 2 0arrow_forward

- time (hours) pH 7.00 7.30 6.99 7.00 Assignment 1 2 7.12 7.25 7.12 7.20 3 720 7.16 720 7.16 4 6.98 7.00 6.94 7.00 5 6.99 6.99 6.99 6.98 6 7.00 6.93 7.02 6.93 7 6.92 7.00 6.92 7.02 Construct the X-Bar charts and R- charts 6.88 6.82 6.94 6.99 7.10 7.00 7.00 7.00 for reporting your results 10 721 7.02 721 7.04 11 7.01 6.86 7.01 6.90 12 6.86 6.98 6.90 6.98 13 6.90 7.00 6.87 7.00 14 7.01 7.04 7.01 7.05 15 7.00 6.95 7.00 6.99 16 7.09 7.20 7.03 7.20 17 6.89 7.14 6.87 7.15 18 6.98 6.80 6.98 6.89 19 7.00 6.90 7.00 6.90 20 7.20 7.00 723 7.00 21 7.04 7.03 7.08 7.00 22 6.90 6.92 6.98 6.92 23 7.00 7.00 7.00 7.00 24 7.00 6.97 7.01 6.98arrow_forwardActivity Preceded By ABCDEFG А ww ww A B,C D E BC F. G Expected Time Regular Crash 6 days 2 day 12 6 4 10 8 C 18 6 2 6 6 2 8 4 Direct Cost Regular Crash $2000 $3800 2000 10000 4000 4600 3900 5000 7600 16000 19600 2000 4000 1000 3400 2800 Requested: (a) Construct a network including the Early and Late Start and Finish times. (b) Identify the normal Critical Path(s) and the normal expected completion time (c) Can the project be crashed to last 18 days? Which activities should be crashed and at what additional cost?arrow_forwardActivity Normal_time Crash_time Normal_cost Crash_cost Slack A 31 28 4500 6700 2 13. 13 5800 5800 0 27 27 5000 5000 0 27 16 4000 6900 2 24 24 5500 5500 0 34 13 4500 6900 0 B C D E F The table shows normal time (in days), crash time (in days), normal cost (in dollars), crash cost (in dollars) and slack time (in days) of activities in a small construction project. According to this table which activity must be crashed first? Assume there is only one criticalarrow_forward

- Please don't provide handwriting solutionarrow_forwardQ4/ The table below shows the duration and direct costs for the activities of a construction project. It is required to caleculate the duration of the project that achieves the lowest possible total cost using the technique of crashing if the indirect costs are 20% from direct cost. Normal Time (NT) Normal Cost (NC) S Crash Time Crash Cost Activity (CT) weeks (CC) S weeks A 6. 1000 3. 7000 В 4 9000 5 10000 C 3 6000 1 10000 D 4 8000 2. 11000 E 6. 1000 4 13000 5 6. D A 3 End Start 6. B Earrow_forwardc) Total cost of crashing the project by 2 days = $_________ (Enter your response as an integer.)arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.