Concept explainers

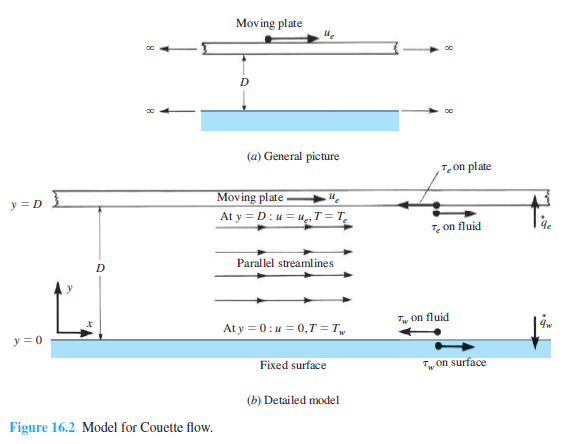

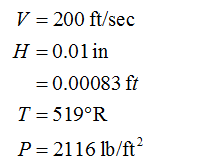

Consider the geometry sketched. The velocity of the upper plate is 200 ft/s, and the two plates are separated by a distance of 0.01 in. The fluid between the plates is air. Assume incompressible flow. The temperature of both plates is the standard sea level value of 519◦R.

(a) Calculate the velocity in the middle of the flow.

(b) Calculate the shear stress.

(c) Calculate the maximum temperature in the flow.

(d) Calculate the heat transfer to either wall.

(e) If the lower wall is suddenly made adiabatic, calculate its temperature.

Given data

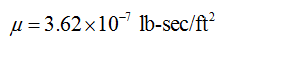

Viscosity of air at the given temperature is

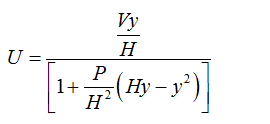

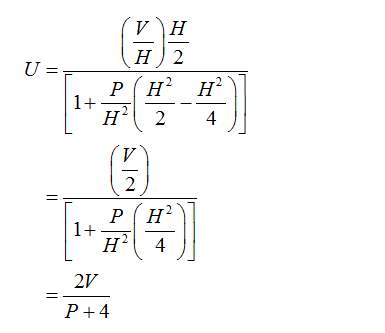

(a). The velocity of the flow between two plates in given by

At the middle of the flow

Therefore, velocity

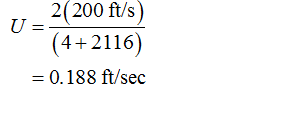

Put the necessary values in above formula we get

Step by stepSolved in 3 steps with 8 images

- An incompressible viscous flow is contained between two parallel plates separated from each other by distance b. as shown in Figure 1. The flow is caused by the movement of the upper plate which has a velocity U, while the bottom plate is fixed. If U =7 m/s and b= 1 cm, and there is no pressure gradient in the flow direction. A.) Start with Navier-Stokes equations and determine the velocity at the point x = 3 cm and y= 0.41 cm. The value of the velocity is.B.) Calculate the magnitude of the vorticity at the same point. The magnitude value of vorticity. C.) Calculate the rate of angular deformation at the same point. The angular deformation valuearrow_forwardThe block of weight W = 50 N is pulled by a weight W0 = 60 N along the surface of a table by means of an inextensible cable and a pulley. Between the block and the table there is a uniform layer of oil of viscosity m = 0.1 Pa-s and clearance h = 2 mm. The contact area is 0.01 m2. Find the terminal velocity U if the table is very long.arrow_forwardWater at 25˚C is flowing past a long cylinder at a velocity of 1.2 m/s in a large tunnel. Theaxis of the cylinder is perpendicular to the direction of flow. The diameter of the cylinder is0.12 m. What is the force per meter length on the cylinderarrow_forward

- Oil Coating: A long, continuous belt is pulled upwards through a chemical oil bath at velocity V0. The belt has rectangular cross-section and has length (L), width into the paper (W). The belt picks up a film of oil of thickness h, density ρ, and dynamic viscosity μ. Gravity g tends to make the oil drain down, but the movement of the belt keeps the fluid from running off completely. Assume fully developed, steady, laminar, incompressible and two-dimensional flow of oil to answer the following questions. Assume that no pressure gradient is needed in the vertical direction to drive the film flow. Also assume that the shear stress at the air-oil interface is zero (free shear condition). Assume no-slip condition for the fluid in contact with the moving belt. Justify any other assumptions you may make. Show all steps. (a) Derive an expression for the two-dimensional velocity field inside the oil film in terms of the known parameters. Clearly indicate your co-ordinates and origin. You must…arrow_forward7. Consider a fluid flow between two parallel fixed plates 5 cm apart. The velocity distribution of the flow is given by u(y) =120(0.05-y²) m/s where y is in meters. The fluid is water at 10°C. Calculate the magnitude of the shear stress along each of the plates.arrow_forwardProblem 1 – A laminar flow fluid of known density (ρ) and viscosity (μ) flows between twoparallel plates with different velocities in the same direction. The top plate has a velocity Utop inthe positive x direction. The bottom plate has a velocity Ubot in the positive x direction. The twoplates are a distance of “a” apart. There is a pressure gradient in the x direction ( ). Derivean expression of the velocity and shear stress profiles between the two platesarrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY