Glencoe Algebra 1, Student Edition, 9780079039897, 0079039898, 2018

18th Edition

ISBN: 9780079039897

Author: Carter

Publisher: McGraw Hill

expand_more

expand_more

format_list_bulleted

Question

Question is attached in SS

greatly aprpeciated taanks

greherherher

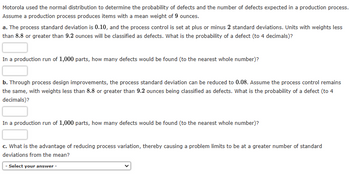

Transcribed Image Text:Motorola used the normal distribution to determine the probability of defects and the number of defects expected in a production process.

Assume a production process produces items with a mean weight of 9 ounces.

a. The process standard deviation is 0.10, and the process control is set at plus or minus 2 standard deviations. Units with weights less

than 8.8 or greater than 9.2 ounces will be classified as defects. What is the probability of a defect (to 4 decimals)?

In a production run of 1,000 parts, how many defects would be found (to the nearest whole number)?

b. Through process design improvements, the process standard deviation can be reduced to 0.08. Assume the process control remains

the same, with weights less than 8.8 or greater than 9.2 ounces being classified as defects. What is the probability of a defect (to 4

decimals)?

In a production run of 1,000 parts, how many defects would be found (to the nearest whole number)?

c. What is the advantage of reducing process variation, thereby causing a problem limits to be at a greater number of standard

deviations from the mean?

- Select your answer -

Expert Solution

arrow_forward

Step 1: Given Information

Given that,

The mean weight of the items is 9 ounces.

The standard deviation is 0.10 ounces.

The process control is set at standard deviation, which means defects are defined as items with weights less than 8.8 or greater than 9.2 ounces.

Trending nowThis is a popular solution!

Step by stepSolved in 5 steps with 20 images

Knowledge Booster

Recommended textbooks for you

Glencoe Algebra 1, Student Edition, 9780079039897...AlgebraISBN:9780079039897Author:CarterPublisher:McGraw Hill

Glencoe Algebra 1, Student Edition, 9780079039897...AlgebraISBN:9780079039897Author:CarterPublisher:McGraw Hill Big Ideas Math A Bridge To Success Algebra 1: Stu...AlgebraISBN:9781680331141Author:HOUGHTON MIFFLIN HARCOURTPublisher:Houghton Mifflin Harcourt

Big Ideas Math A Bridge To Success Algebra 1: Stu...AlgebraISBN:9781680331141Author:HOUGHTON MIFFLIN HARCOURTPublisher:Houghton Mifflin Harcourt

Glencoe Algebra 1, Student Edition, 9780079039897...

Algebra

ISBN:9780079039897

Author:Carter

Publisher:McGraw Hill

Big Ideas Math A Bridge To Success Algebra 1: Stu...

Algebra

ISBN:9781680331141

Author:HOUGHTON MIFFLIN HARCOURT

Publisher:Houghton Mifflin Harcourt