Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN: 9781259696527

Author: J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Question

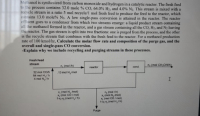

Transcribed Image Text:Methanol is synthesized from carbon monoxide and hydrogen in a catalytic reactor. The fresh feed

to the process contains 32.0 mole % CO, 64.0% H, and 4.0% N2. This stream is mixed with a

reeycle stream in a ratio 5 mol recycle/l mol fresh feed to produce the feed to the reactor, which

contains 13.0 mole% N2. A low single-pass conversion is attained in the reactor. The reactor

effluent goes to a condenser from which two streams emerge: a liquid product stream containing

all the methanol formed in the reactor, and a gas stream containing all the CO, H2, and N2 leaving

the reactor. The gas stream is split into two fractions: one is purged from the process, and the other

is the recycle stream that combines with the fresh feed to the reactor. For a methanol production

rate of 100 kmol/hr, Calculate the molar flow rate and composition of the purge gas, and the

overall and single-pass CO conversion.

-Explain why we include recycling and purging streams in these processes.

Fresh Feed

stream

n, (mol h)

n (mol CH OHh

reactor

cond.

32 mol CO

64 mol H,/h

4 mol Nh

13 mol N, mol

X, (mel N me)

K, (mol CO/ mol)

1, (mol H,/h)

(mol /h)

K, mol N, imol)

x (mol CO/ mol)

1-, tmol H,/hj)

Purge

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 8 steps with 12 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, chemical-engineering and related others by exploring similar questions and additional content below.Similar questions

- 2. 100 mol/h of gaseous ethane is burned with excess air. The fuel is mixed with air before entering the furnace; fuel-air mixture is fed to the furnace at 25oC and 1 atm. All the ethane is consumed in the combustion reaction that occurs in the furnace. A cooling water jacket surrounding the furnace removes all of the heat generated by the combustion reaction. The stack gas leaves the furnace at 25oC and 1 atm and contains 5.32 mole% CO2, 1.60% CO, 7.32% O2 and the balance H2O and N2.a. Use Hess’s Law and the Heat of Combustion to calculate ∆??o (kJ/mol) for complete and incomplete combustion of ethane. b. Calculate the molar percentage of ethane in the fuel gas and the percentage excess air fed to the reactor.c. Calculate rate of heat transferred to the cooling water jacket in kW.arrow_forward#3 The first step in the reaction sequence for the production of nitric acid via the oxidation of ammonia is: 4NH3 + 502 2 4NO + 6H2O 75% conversion is achieved with an equimolar mixture of ammonia and oxygen fed at the rate of 100 mol/h. Determine the outlet compositions. (Hint: determine the limiting reactant).arrow_forwardFresh methanol (CH3OH) reactant is combined with recycled reactant and vaporized before being sent to a fixed-bed reactor. The reactor effluent is then cooled before being sent to the first of two distillation columns. DME (CH3)2O product is taken overhead from the first column. The second column separates the water from the unused methanol. The methanol is recycled back to the front end of the process, and the water is sent to wastewater treatment to remove trace amounts of organic compounds. Draw a block flow diagram for this process. The main reaction is 2CH3OH → (CH3)2O + H2Oarrow_forward

- 1. A fresh stream of pure ethane(C2H6) combined with a recycle stream are fed to a combustion chamber and burned with excess air. The gas mixture exiting the chamber is fed to a filter where 70% of the ethane is removed and recycled to the reactor inlet. The stack gas removed from the filter contains 10.1% 02, 4.5% CO2, 1.5% CO, 0.3% ethane and balanced N2 and H20. Calculate recycle ratio (moles of recycle/moles of fresh feed), conversion of ethane in combustion chamber, percentage of excess for air (%excess) and the molar composition of the stack gas leaving the filter.arrow_forwardMaterial and energy balancearrow_forwardA mixture of 90g of N2, 165g of O2 and 45g of Cl2 is introduced to a reactor where the following chemical reaction is carried out in the gas phase, If the reaction has a yield of 85% yield. Calculate the products of the reaction at the outlet. N2+O2→N2O4arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Introduction to Chemical Engineering Thermodynami...

Chemical Engineering

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind...

Chemical Engineering

ISBN:9781118431221

Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:WILEY

Elements of Chemical Reaction Engineering (5th Ed...

Chemical Engineering

ISBN:9780133887518

Author:H. Scott Fogler

Publisher:Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:9781285061238

Author:Lokensgard, Erik

Publisher:Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:9780072848236

Author:Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:McGraw-Hill Companies, The