Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

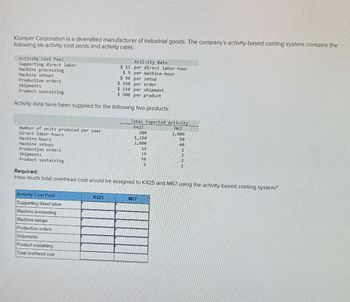

Transcribed Image Text:Klumper Corporation is a diversified manufacturer of industrial goods. The company's activity-based costing system contains the

following six activity cost pools and activity rates

Activity Cost Pool

Supporting direct labor

Machine processing

Machine setups

Production orders

Shipments

Product sustaining

Activity Rate

$ 11 per direct labor-hour

$5 per machine-hour

$50 per setup

$ 150 per order

$ 110 per shipment

$ 900 per product

Activity data have been supplied for the following two products

Total Expected Activity

Number of units produced per year

Direct labor-hours

Machine-hours

Machine setups

Production orders

Shipments

K425

M67

200

2,000

1,150

50

2,800

40

19

2

19

38

2

2

Product sustaining

Required:

How much total overhead cost would be assigned to K425 and M67 using the activity-based costing system?

Activity Cost Pool

K425

M67

Supporting direct labor

Machine processing

Machine setups

Production orders

Shipments

Product sustaining

Total overhead cost

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps

Knowledge Booster

Similar questions

- Please do not write in column A Problem 6 Given the following forecast and cost information, determine the total cost of a plan that uses regular time production output of 600 units per month, overtime is used when needed up to a maximum of 60 units per month, and subcontracting is used if additional units are needed to meet the forecast. Regular time cost $ 40.00 per unit Overtime cost $ 60.00 per unit subcontracting cost $ 80.00 per unit holding cost $ 10.00 per unit per month Production Inventory Costs Month Forecast Level Production Overtime Subcontracting Total Holding Cost Regular Time Overtime Subcontracting Total Cost 1 563 0 2 608 3 648 4 668 5 666 6 688 Totalsarrow_forwardThe Silver Star Bicycle Company will be manufacturing both men's and women's models of its Easy-Pedal 10-speed bicycles during the next two months. Management wants to develop a production schedule indicating how many bicycles of each model should be produced in each month. Current demand forecasts call for 150 men's and 125 women's models to be shipped during the first month and 200 men's and 150 women's models to be shipped during the second month. Additional data are shown: Production Labor Requirements (hours) Current Model Costs Manufacturing Assembly Inventory Men's $120 2.0 1.5 20 Women's $90 1.6 1.0 30 Last month the company used a total of 1000 hours of labor. The company's labor relations policy will not allow the combined total hours of labor (manufacturing plus assembly) to increase or decrease by more than 100 hours from month to month. In addition, the company charges monthly inventory at the rate of 2% of the production cost based on the inventory levels at the end of…arrow_forwardplease help me with Question 3 thanks! Demand forecasts for 2021 are as follows: Month Demand Jan 140,000 Feb 78,900 Mar 85,800 Apr 89,100 May 123,600 Jun 136,350 Jul 120,450 Aug 106,950 Sep 121,950 Oct 135,750 Nov 87,000 Dec 93,300 Each worker can produce 900 products per month and is paid $1500 per month. Assume that at the end of last year, the company has 100 employees working on the production line. Hiring and layoff (firing) decisions are made at the beginning of each month, and associated costs are charged at that time. It costs the company $400 to hire and $800 to lay off a worker. The company incurs holding cost for the amount of ending inventory in each month, and incurs backorder cost at the end of each month for any unfilled orders. The company incurs $2 per month for holding one unit in inventory and $4 per unit backorder. 1 Prepare a level aggregate plan. Under this level aggregate plan, how…arrow_forward

- Demand at Nature Trails Ski Resort has a seasonal pattern.Demand is highest during the winter, as this is the peak ski season.However, there is some ski demand in the spring and even fallmonths. Th e summer months can also be busy as visitors oft encome for summer vacation to go hiking on the mountain trails.Th e owner of Nature Trails would like to make a forecast for eachseason of the next year. Total annual demand has been estimatedat 4000 visitors. Given the last two years of historical data, what isthe forecast for each season of the next year?arrow_forwardThe Cheyenne Hotel in Big Sky, Montana, has accumulated records of the total electrical costs of the hotel and the number of occupancy-days over the last year. An occupancy-day represents a room rented for one day. The hotel’s business is highly seasonal, with peaks occurring during the ski season and in the summer. Month Occupancy-Days Electrical Costs January 2,630 $ 10,783 February 3,130 $ 12,833 March 3,640 $ 13,583 April 1,090 $ 4,469 May 1,770 $ 7,257 June 1,730 $ 7,093 July 4,440 $ 14,854 August 3,860 $ 13,815 September 2,170 $ 8,897 October 1,210 $ 4,961 November 1,790 $ 7,339 December 2,930 $ 12,013 Required: 1. Using the high-low method, estimate the fixed cost of electricity per month and the variable cost of electricity per occupancy-day. (Do not round your intermediate calculations. Round your Variable cost answer to 2 decimal places and Fixed cost element answer to nearest whole dollar amount.) What other factors in addition to…arrow_forwardA store’s demand figures are given in the table. According to this, what is the linear regression forecast for Week 12?arrow_forward

- If Mr. White proceeds with the manufacturing expansion he feels he will need to alter the current compensation package for his sales team in order to make sure Cottage Living can sell the additional units at market price. In an attempt to retain talented salespeople he has previously offered a very competitive yearly salary of $70,000 plus benefits and 4 weeks paid vacation. This pay structure has worked well in the past to attract loyal employees and to create a positive work environment at Cottage Living. There are currently 5 permanent salespeople. However, given how strong demand in 2019 and 2020 for Cottage Living products has been Mr. White feels that his sales team has been lacking motivation. They have also been taking their vacations during high demand months from May-August (he is not interested in dictating when people take their vacation). He is worried that if there is an increase in Cottage Living’s inventory, the poor sales habits that his team has picked up during the…arrow_forwardThe table below provides the aggregate plan of production by a firm. It is known that the firm uses a chase plan. The firm’s labor cost is $10/unit, hiring cost is $200 per unit of increase, and unit firing cost is $400 per unit of decrease in production. Given this information, what is the number in the cell with the question mark?arrow_forwardGiven the preceding information, what are Jerry’s options? How should they be evaluated? Make assumptions where necessary.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.