Managerial Accounting: The Cornerstone of Business Decision-Making

7th Edition

ISBN: 9781337115773

Author: Maryanne M. Mowen, Don R. Hansen, Dan L. Heitger

Publisher: Cengage Learning

expand_more

expand_more

format_list_bulleted

Question

Please solve this question general accounting

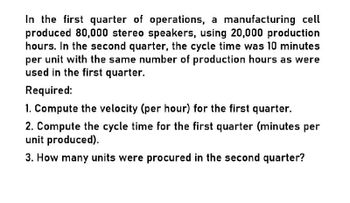

Transcribed Image Text:In the first quarter of operations, a manufacturing cell

produced 80,000 stereo speakers, using 20,000 production

hours. In the second quarter, the cycle time was 10 minutes

per unit with the same number of production hours as were

used in the first quarter.

Required:

1. Compute the velocity (per hour) for the first quarter.

2. Compute the cycle time for the first quarter (minutes per

unit produced).

3. How many units were procured in the second quarter?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps

Knowledge Booster

Similar questions

- Computador has a manufacturing plant in Des Moines that has the theoretical capability to produce 243,000 laptops per quarter but currently produces 91,125 units. The conversion cost per quarter is 7,290,000. There are 60,750 production hours available within the plant per quarter. In addition to the processing minutes per unit used, the production of the laptops uses 10 minutes of move time, 20 minutes of wait time, and 5 minutes of rework time. (All work is done by cell workers.) Required: 1. Compute the theoretical and actual velocities (per hour) and the theoretical and actual cycle times (minutes per unit produced). 2. Compute the ideal and actual amounts of conversion cost assigned per laptop. 3. Calculate MCE. How does MCE relate to the conversion cost per laptop?arrow_forwardA manufacturing cell within a value stream has three processes and the following associated processing times: Drilling: 12 minutes Inserting: 6 minutes Finishing: 2 minutes How many units can the cell produce per hour (on a continuous running basis)? a. 10 units per hour b. 3 units per hour c. 5 units per hour d. 30 units per hourarrow_forwardA manufacturing cell within a value stream is structured with four processes and associated processing times (for one unit): Molding: 6 minutes Grinding: 5 minutes Polishing: 5 minutes Finishing: 4 minutes How many units can the cell produce per hour (on a continuous running basis)? a. 3 units per hour b. 12 units per hour c. 15 units per hour d. 10 units per hourarrow_forward

- Prakesh Company has the following data for one of its manufacturing cells: Maximum units produced in a month: 62,500 units Actual units produced in a month: 56,250 units Hours of production labor in one month: 10,000 hours Required: 1. Compute the theoretical cycle time. Round your answer to the nearest whole minute.fill in the blank 1 minutes per unit 2. Compute the actual cycle time. Round your answer to the nearest whole minute.fill in the blank 2 minutes per unit 3. Compute the theoretical velocity. Round your answer to the nearest whole unit.fill in the blank 3 units per hour 4. Compute the actual velocity. Round your answer to the nearest whole unit.fill in the blank 4 units per hourarrow_forwardDelko Company has the following data for one of its manufacturing plants: Maximum units produced in a quarter (3-month period): 250,000 units Actual units produced in a quarter (3-month period): 210,000 units Productive hours in one quarter: 25,000 hours The actual cycle time for Indy Company is 7.14 minutes, and the theoretical cycle time is 6 minutes. Required: 1. Calculate the amount of processing time and the amount of nonprocessing time. If required, round your answers to two decimal places. Processing time minutes Nonprocessing time minutes 2. Calculate the MCE. If required, round your answer to nearest whole number.arrow_forwardDelko Company has the following data for one of its manufacturing plants: Maximum units produced in a quarter (3-month period): 250,000 units Actual units produced in a quarter (3-month period): 199,000 units Productive hours in one quarter: 25,000 hours Required: 1. Compute the theoretical cycle time (in minutes). minutes per unit 2. Compute the actual cycle time (in minutes). Round your answer to two decimal places. minutes per unit 3. Compute the theoretical velocity in units per hour. units per hour 4. Compute the actual velocity in units per hour. Round your answer to two decimal places. units per hourarrow_forward

- Cycle Time and Velocity In the first quarter of operations, a manufacturing cell produced 115,000 stereo speakers, using 20,000 production hours. In the second quarter, the cycle time was 10 minutes per unit with the same number of production hours as were used in the first quarter. Required: 1. Compute the velocity (per hour) for the first quarter. If required, round your answer to two decimal places.fill in the blank 1 of 1 units per hour 2. Compute the cycle time for the first quarter (minutes per unit produced). If required, round your answer to two decimal places.fill in the blank 1 of 1 minutes per unit 3. How many units were produced in the second quarter?fill in the blank 1 of 1 unitsarrow_forwardJohnson Electronics manufactures a power supply used in a variety of electronics products, including printers, modems, and routers. The demand for the part is 7,500 units per week. The production of the power supply requires six different manufacturing operations, each in sequence and each having the following processing times. The net available time to work is 52 hours per week, using two shifts. Operation Operation 1 Operation 2 Operation 3 Operation 4 Operation 5 Operation 6 Required: 1. What is the Takt time, in seconds, for this product? (Round your final answer to the nearest whole number.) Takt time Processing Time (seconds) 23 20 25 22 30 25 Yes No seconds per unit 2. Is the processing line properly balanced for this product?arrow_forwardA manual assembly line is being designed for a product with annual demand = 100,000 units. The line will operate 50 wks/year, 5 shifts/wk, and 7.5 hr/shift. Work units will be attached to a continuously moving conveyor. Work content time = 42.0 min. Assume line efficiency E = 0.97, balancing efficiency Eb = 0.92, and repositioning time Tr = 6 sec. Determine: (a) hourly production rate to meet demand, (b) number of workers required.arrow_forward

- Corazon Manufacturing Company has a purchasing department staffed by five purchasingagents. Each agent is paid $28,000 per year and is able to process 4,000 purchase orders. Lastyear, 17,800 purchase orders were processed by the five agents.Required:1. Calculate the activity rate per purchase order.2. Calculate, in terms of purchase orders, the:a. total activity availabilityb. unused capacity3. Calculate the dollar cost of:a. total activity availabilityb. unused capacity4. Express total activity availability in terms of activity capacity used and unused capacity. 5. What if one of the purchasing agents agreed to work half time for $14,000? How many pur-chase orders could be processed by four and a half purchasing agents? What would unused capacity be in purchase orders?arrow_forwardJohnson Electronics manufactures a power supply used in a variety of electronics products, including printers, modems, and routers. The demand for the part is 7,400 units per week. The production of the power supply requires six different manufacturing operations, each in sequence and each having the following processing times. The net available time to work is 46 hours per week, using two shifts. Processing Time Operation (seconds) Operation 1 16 Operation 2 13 Operation 3 22 Operation 4 15 Operation 5 28 Operation 6 19 Required: 1. What is the Takt time, in seconds, for this product? (Round your final answer to the nearest whole number.) Takt time seconds per unit 2. Is the processing line properly balanced for this product? Yes ○ Noarrow_forwardSifton Electronics Corporation manufactures and assembles electronic motor drives for video cameras. The company assemble. the motor drives for several accounts. The process consists of a lean cell for each customer. The following information relates t only one customer's lean cell for the coming year. For the year, projected labor and overhead was $3,120,000 and materials costs were $31 per unit. Planned production included 5,120 hours to produce 16,000 motor drives. Actual production for August was 1,870 units, and motor drives shipped amounted to 1,480 units. Conversion costs are applied based on units of production From the foregoing information, determine the cell conversion cost rate. a. $2,108.11 b. $195.00 c. $1,668.45 d. $609.38arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Managerial Accounting: The Cornerstone of Busines...AccountingISBN:9781337115773Author:Maryanne M. Mowen, Don R. Hansen, Dan L. HeitgerPublisher:Cengage Learning

Managerial Accounting: The Cornerstone of Busines...AccountingISBN:9781337115773Author:Maryanne M. Mowen, Don R. Hansen, Dan L. HeitgerPublisher:Cengage Learning Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning

Managerial Accounting: The Cornerstone of Busines...

Accounting

ISBN:9781337115773

Author:Maryanne M. Mowen, Don R. Hansen, Dan L. Heitger

Publisher:Cengage Learning

Cornerstones of Cost Management (Cornerstones Ser...

Accounting

ISBN:9781305970663

Author:Don R. Hansen, Maryanne M. Mowen

Publisher:Cengage Learning