Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

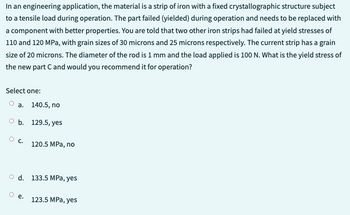

Transcribed Image Text:In an engineering application, the material is a strip of iron with a fixed crystallographic structure subject

to a tensile load during operation. The part failed (yielded) during operation and needs to be replaced with

a component with better properties. You are told that two other iron strips had failed at yield stresses of

110 and 120 MPa, with grain sizes of 30 microns and 25 microns respectively. The current strip has a grain

size of 20 microns. The diameter of the rod is 1 mm and the load applied is 100 N. What is the yield stress of

the new part C and would you recommend it for operation?

Select one:

a. 140.5, no

Ob. 129.5, yes

OC.

120.5 MPa, no

O d. 133.5 MPa, yes

O e. 123.5 MPa, yes

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 3 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- (2) Consider a homogeneous structure made out of metal subjected to homogeneous boundary conditions t = σn. For o corresponding to uniaxial, biaxial and shear stress state, calculate the stress at which the material yields.arrow_forwardHelp me pleasearrow_forwardA metallic tube has an outer diameter of 500 mm and a wall thickness of 30 mm (Figure 4). The working internal pressure of the tube is 15 MPa and the fracture toughness of the material (K₁c) ranges from 40 MN/m³/2 to 50 MN/m³/2. Select a value for Kic and determine the size of the largest flaw the tube can contain. Assume that for this geometry K σφπα. = 30 mm! 500 mm Figure surface flaws 4 (not to scale)arrow_forward

- Need help on this Qarrow_forwardConsider a dislocation condition as shown below. A) what is the strain state in the upper region and B) how would addition of small impurity atoms in the region indicated by "*"s change it? oooooo OOOOO DO Select one: a. Compressive, would reduce compressive strain O b. Tensile, would decrease tensile strain O C. Compressive, would increase compressive strain Od. Tensile, would increase tensile strain Oe. Shear, would increase compressive strainarrow_forwardIn order to find out the effects of the grain sizes on the mechanical strength of a metal, three different grain sizes of 10 µm, 500 nm and 10 nm were produced. What will be the yield stresses of these same metals at different average grain sizes? The yield strength for a grain or reference point is 78 MPa, while the material proportional constant is 29.2 MPa-mm1/2.arrow_forward

- The yield strength for an alloy that has an average grain diameter of 5.2 x 102 mm is 110 MPa. At a grain diameter of 6.3 x 103 mm, the yield strength increases to 251 MPa. At what grain diameter, in mm, will the yield strength be 222 MPa? d = mmarrow_forwardConsider a single crystal of a hypothetical metal that has the BCC crystal structure. A stress of 50 MPa is applied in the [101] direction of the BCC unit cell.a. Determine the most favourable slip direction for the (011) slip plane of the BCC unit cell. ⟨111⟩ is the family of directions with the highest linear density in the BCC unit cell.b. If τcrss = 27.5 MPa, determine if the single crystal yields. If not, what stress level is required?c. What is the minimum stress at which the BCC single crystal yields?arrow_forward9. Consider a metal rod, whose grain size can be adjusted by different processing techniques. The graph below shows how the yield stress changes with grain size d; the x-axis is logarithmic. The curve reaches a limiting value of 60 MPa as indicated by the horizontal dashed line on the y-axis, for very large grain sizes. Also, you are given the information that at d = 25 microns (vertical dashed line), the yield stress is 100 MPa. Using this information, what will be the yield stress at d = 5 microns? Select the closest numerical value. Use the Hall-Petch relation in working out your answer. Yield stress (MPa) ● ● 228882S 130 120 110 100 60 10⁰ 10¹ 10² Grain size d (microns) 132.4 MPa 149.4 MPa 165.2 MPa 156.3 MPa 10arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY