Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

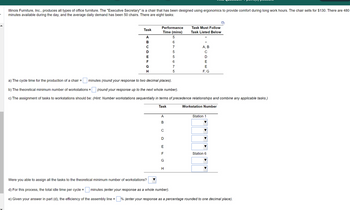

Transcribed Image Text:Illinois Furniture, Inc., produces all types of office furniture. The "Executive Secretary" is a chair that has been designed using ergonomics to provide comfort during long work hours. The chair sells for $130. There are 480

minutes available during the day, and the average daily demand has been 50 chairs. There are eight tasks:

Task

ABCDEFGH

Performance

Time (mins)

5

Were you able to assign all the tasks to the theoretical minimum number of workstations?

A B C D E FL

G

5675768

H

Task Must Follow

Task Listed Below

a) The cycle time for the production of a chair = minutes (round your response to two decimal places).

(round your response up to the next whole number).

b) The theoretical minimum number of workstations =

c) The assignment of tasks to workstations should be: (Hint: Number workstations sequentially in terms of precedence relationships and combine any applicable tasks.)

Task

A, B

CDEE

F, G

Workstation Number

Station 1

Station 6

d) For this process, the total idle time per cycle =

minutes (enter your response as a whole number).

e) Given your answer in part (d), the efficiency of the assembly line = % (enter your response as a percentage rounded to one decimal place).

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps with 3 images

Knowledge Booster

Similar questions

- Mach 10 is a one-person sailboat designed to be used in the ocean. Manufactured by Creative Leisure, Mach 10 can handle 40-mph winds and seas over 10 feet. The final assembly plant is in Cupertino, California. At this time, 300 minutes are available each day to manufacture Mach 10. The daily demand is 60 boats. Given the following information: Task ABCDEFGH I Performance Time (mins) 1 1 3 1 3 1 1 2 1 Predecessors A A C C D, E, F B G, H a) The correct precedence relationship with one of the possible assignment of tasks to workstations is shown in Fig. 3. The operating efficiency of the assembly line with 3 workstations shown in the figure chosen above=% (enter your response as a percentage rounded to one decimal place). C Fig. Fig. 2 Fig. 3 E Farrow_forwardplease answer all parts within 30 minutes. else negative ratings.arrow_forwardANSWER D, E, F ONLYarrow_forward

- Scenario C: Suppose you are given the process flowchart shown below. There are no buffers between tasks. Task 1 and 2 produce "Part A", and Task 3 and 4 produce "Part B"; Task 5 assembles each unit of a finished product by combining one unit of "Part A" with one unit of "Part B". Using this, answer the next 3 questions: Tpt Cap. = 10 units/hour- Tpt Cap. = 15 units/hour Task 1 5 ● 8 10 15 20 Task 3 Tpt Cap. = 5 units/hour Task 2 Tpt Cap. = 8 units/hour Task 4 Tpt Cap. = 20 units/hour Task 5 In this scenario, how many units would Task 5 actually produce each hour? Pick the closest answer. FGIarrow_forwardPlease solve, please solve exact question, thank you for your timearrow_forwardThe table below shows the time for each work element in an manual assembly process, along with the predecessor(s) required for each element. The ideal cycle time is 1.4 minutes, the repositioning time is 0.1 minutes, and there is one worker at each station. Work element A B C D E F G H I J Time (minutes) 0.7 0.4 0.2 0.3 0.5 0.4 0.6 0.5 0.3 0.2 Immediate predecessors - A A B B C E,F D,E G,H I 1. Using the ranked positional weights method, assign work elements to stations.arrow_forward

- What is the required workstation cycle time to meet the desired output rate, and how can you balance this line using the longest task time (filling in the chart below)? Note: Leave no cells blank - be certain to enter "0" wherever required.arrow_forwardHi! I need a little help with D. I can't figure out how to calculate the efficiency. Can you explain it to me?arrow_forwardInput Area Cost Per Hour $1500.00 Outage Duration (hours) 3 Output Area Total Cost for Outage $4500.00 One-Variable Data Table: Cost Outage Impact Analysis Duration (hr) (Cost) 1 $1500.00 1.5 $2250.00 2 $3000.00 2.5 $3750.00 3 $4500.00 3.5 $5250.00 4 $6000.00 4.5 $6750.00 5 $7500.00 Given the data above Which What If Analysis tool is the worksheet using? Provide a description of the What If Analysis tool and why it was used in the worksheet. Interpret what the data means. Discuss what it means for the business.arrow_forward

- Please help solve this problem!!arrow_forward1.The standard time fixed for the worker is 20 hours to complete a job. If a worker completes the job in 16 hours and the wage for one hour is 4 Rials, Calculate incentive as per Halsey plan and Rowan plan and find out which is beneficial to employerarrow_forwardHi, I need help solving the remainder of this Operations Management problem. Thank you! *Notes: - The correct answer to part B is also known, "66.8" - "13.4" and "13.5" were both attempted for part C and are not the correct answersarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.