Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

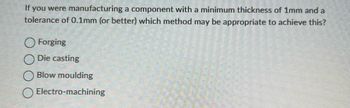

If you were manufacturing a component with a minimum thickness of 1mm and a

tolerance of 0.1mm (or better) which method may be appropriate to achieve this?

Transcribed Image Text:If you were manufacturing a component with a minimum thickness of 1mm and a

tolerance of 0.1mm (or better) which method may be appropriate to achieve this?

Forging

O Die casting

Blow moulding

Electro-machining

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps

Knowledge Booster

Similar questions

- A siilicon boule has been processed through grinding to provide a cylinder whose diameter = 281 mm and whose length = 899 mm. Next, it will be sliced into wafers 0.8 mm thick using a cut-off saw with a kerf = 0.5 mm. The wafer thus produced will be used to fabricate as many IC chips as possible for the personal computer market. Each IC has a market value to the company of $108. Each chip is square with 17 mm on a side. The processable area of each wafer is defined by a diameter = 265 mm. Estimate the value of all of the IC chips that could be produced (in $), asssuming an overall yield of 84% good product.arrow_forwardWhat part provides the most manufacturing tolerance and is easiest to work with, part 1 or part 2? Explain why.arrow_forwardIn GD&T Coaxiality is that condition where the axes of two or more surfaces of revolution are _____________. There is a misconception that centerlines or the tolerance block control the ____________________ between two cylinders.arrow_forward

- Which order arranges the following manufacturing processes from the least precise to the most precise tolerance limits?POSSIBLE ANSWERS1 . Turning, grinding, casting2 . Casting, turning, grinding3 . Casting. grinding, turning4 . Turning, casting, grindingarrow_forwardCalculate the maximum limit if the tolerance is 0.004 cm and the minimum limit is 0.985 cm.arrow_forwardWhat is relation between product tolerance (engineering tolerance) and process variation.? Explain in some details showing some representation. Analyze the following study in terms: Components of variations and their contributions X Chart and R Chartarrow_forward

- A GO/NO-GO snap gage is required to inspect the diameter of a shaft that is 1.000 ± 0.020. A wear allowance of 2% of the entire tolerance band is applied to the GO side. Determine (a) the nominal sizes of (a) the GO gage and (b) the NO-GO gagearrow_forwardWhy might a 50 division vernier caliper not be more advantageous, in terms of measurement accuracy, than a 10 division vernier caliper?arrow_forwardWhat is the concept of accuracy? Explain. How do you measure accuracy? How do you measure thread pitch diameter? Why is it important? Given the following information and (TPI: thread per inch -13), determine the pitch diameter.arrow_forward

- A specification for a stainless steel bar is given as follows: length: 10.40 cm + 0.02 cm Find the upper limit, the lower limit, and the tolerance intervalarrow_forwardA reciprocating type ball-on-disc tribometer was used to measure the tribological behaviour of the thermally sprayed cobalt oxide coatings against the alumina (Ø 6.35 mm) counterface. After wear testing at high temperatures, the area of the wear tracks was 300 μm² measured by a white light microscope. The following parameters were used for sliding wear testing. Parameters Applied load (N) Sliding velocity (cm/s) Test frequency (Hz) Track length (mm) Total sliding cycles Total sliding distance (m) Values 10 3.14 1 10 2500 50 Determine the wear volume in mm³ that was removed during the sliding process and the specific wear rate (mm³/N.m.).arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY