Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

What part provides the most manufacturing tolerance and is easiest to work with, part 1 or part 2? Explain why.

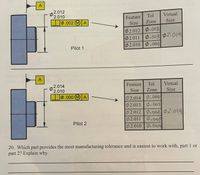

Transcribed Image Text:The image depicts two engineering diagrams labeled "Pilot 1" and "Pilot 2," each with associated dimensions and tolerance zones.

For **Pilot 1**:

- Two diameters are shown: 2.012 and 2.010.

- A geometric characteristic symbol indicates a tolerance with a maximum material condition (MMC) modifier.

- The tolerance is specified as \(\diameter 0.002\).

Adjacent to the diagram is a table listing the following:

- **Feature Size:** Ranges from \(\diameter 2.012\) to \(\diameter 2.010\)

- **Tol Zone:** 0.002 to 0.004

- **Virtual Size:** \(\diameter 2.014\)

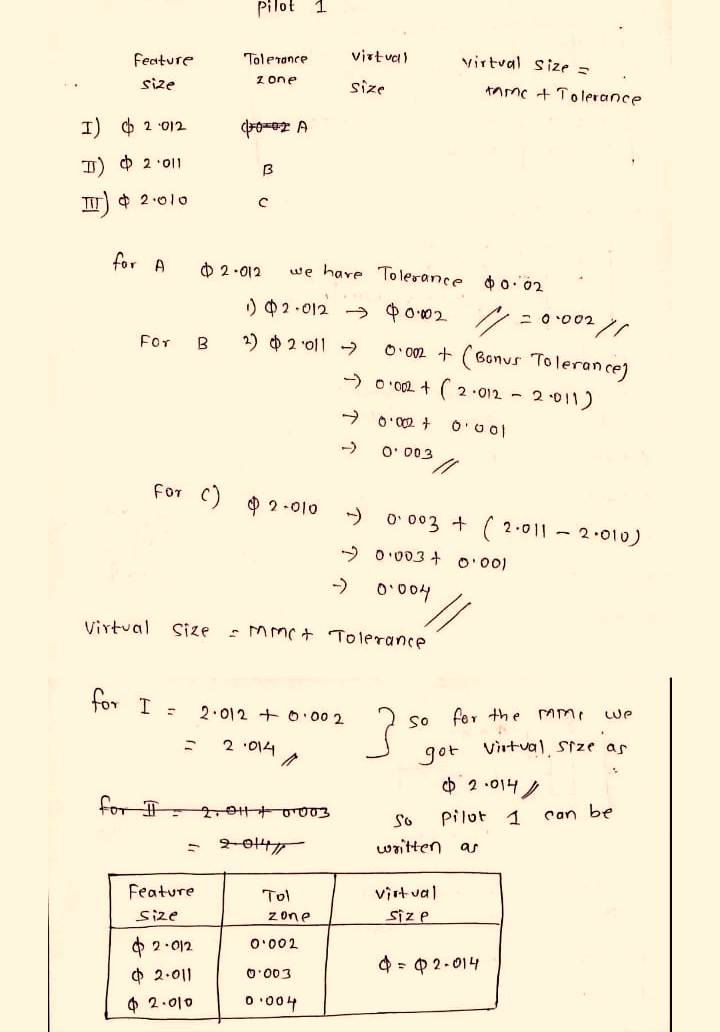

For **Pilot 2**:

- Two diameters are shown: 2.014 and 2.010.

- A similar geometric characteristic symbol with MMC modifier is used.

- The tolerance is specified as \(\diameter 0.000\).

The adjacent table lists:

- **Feature Size:** Ranges from \(\diameter 2.014\) to \(\diameter 2.010\)

- **Tol Zone:** 0.000 to 0.004

- **Virtual Size:** \(\diameter 2.014\)

Below the diagrams, a question is presented:

"20. Which part provides the most manufacturing tolerance and is easiest to work with, part 1 or part 2? Explain why."

The differences in tolerance specifications indicate varying levels of ease in manufacturing based on the required precision and feature allowances.

Expert Solution

arrow_forward

Step 1

Step by stepSolved in 3 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Which three of the following are names given to the three regions in the typical wear growth curve: (Choose three answers) temperature region diffusion region failure region 0000000 accelerated wear region break-in period steady-state wear abrasion regionarrow_forwardWhich order arranges the following manufacturing processes from the least precise to the most precise tolerance limits?POSSIBLE ANSWERS1 . Turning, grinding, casting2 . Casting, turning, grinding3 . Casting. grinding, turning4 . Turning, casting, grindingarrow_forwardWhy might a 50 division vernier caliper not be more advantageous, in terms of measurement accuracy, than a 10 division vernier caliper?arrow_forward

- What are two differences between clamshell/beach markings and fatigue striations?arrow_forwardAt operating stress of 420MPa, the number of cycles to fail a specimen is 65 cycles. At operating stress of 360MPa, the number of cycles to fail the specimen is 390 cycles, and at operating stress of 130MPa, the number of cycles to fail the specimen is 11,900 cycles. A test sequence as follows is designed: first, operating stress of 420MPa for 7 cycles, second, operating stress of 360MPa for 65 cycles, and third, operating stress of 130MPa for 325 cycles. Determine at what number of cycle and which operating stress level the specimen would be expected to fail if the above sequence is repeated.arrow_forwardA reciprocating type ball-on-disc tribometer was used to measure the tribological behaviour of the thermally sprayed cobalt oxide coatings against the alumina (Ø 6.35 mm) counterface. After wear testing at high temperatures, the area of the wear tracks was 300 μm² measured by a white light microscope. The following parameters were used for sliding wear testing. Parameters Applied load (N) Sliding velocity (cm/s) Test frequency (Hz) Track length (mm) Total sliding cycles Total sliding distance (m) Values 10 3.14 1 10 2500 50 Determine the wear volume in mm³ that was removed during the sliding process and the specific wear rate (mm³/N.m.).arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY