The rate of a forward reaction is equal to the product of the rate constant for the forward reaction and concentration of reactants. Rate constant is dependent on temperature, but not concentration. An increase in temperature increases the rate constant, and hence the rate. An increase in concentration increases the rate, but not the rate constant.

Similarly, there is rate constant for the backward reaction. Equilibrium constant is the ratio of forward reaction rate constant to the backward reaction rate constant. It simplifies to the ratio of concentration of products to the concentration of the reactants.

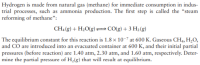

The reaction taking place is,

All the components are gases.

Let us assume that all the gases are ideal and the temperature remains constant.

The equilibrium constant is given as,

we know that ,

where,

is the equilibrium constant in terms of partial pressure

is the universal gas constant

is the absolute temperature

is the difference between the stoichiometric constants of products and the reactants,

i.e

Hence,

we know,

Where,

P represents the partial pressures of the components.

Let us put up a flow data for the reactants and product.

Let x be the reduce in pressure due to the reaction

| Component | Initial Pressure(atm) | Equilibrium pressure(atm) |

| 1.4 | ||

| 2.3 | ||

| 1.6 | ||

| 0 |

We know,

Substituting the equilibrium pressures,

Solving the above equation,

we get,

Since the value of x cannot be negative or imaginary, we will be considering

Hence, the equilibrium pressures of the components are:

Step by stepSolved in 3 steps

- Ref Example 9.5-3: The dehydrogenation of ethanol to form acetaldehyde is carried out in a continuous adiabatic reactor. Ethanol vapor is fed to the reactor at 400 °C, and a conversion of 30% is obtained. Calculate the product Temperature. CpSisto 48 có xio 7 +2.38 X10 T 05 x 10-872 C₂H5OH(v)→ CH3CHO(v) + H₂(g) Solution REACTOR 100 mol C₂H5OH(v) 400°C C₂H50H (V), CH³ CHO (V), H₂ a 70 mol C₂H5OH(v) 30 mol CH3CHO(v) 30 mol H₂(g) Tad (°C)arrow_forwardA sample of 260.0 of liquid water is initially at a temperature of 75.0ºC. If that water is heated by the combustion of 26.00 grams of coal (carbon) to form carbon dioxide. Assume all the heat from combustion goes into the water. Determine the final state and temperature of the H2O. Explain the determination of the energy produced by combustion of the coal, the amount of energy used to heat the liquid water, the energy needed to vaporize the liquid water, and the final temperature determination.arrow_forwardMonochlorobenzene (M) is produced commercially by the direct catalytic chlorination of benzene (B) at 50.0 °C and 140.0 kPa absolute. In the process, dichlorobenzene (D) is generated as a co-product: CH6 + Cl2- CgH;CI + HCI CGH5CI + Cl2 – C&H4CI2 + HCI Liquid and gas streams leave the reactor. The liquid contains 39.2 wt% M, 32.6 % D, and the remainder unreacted B. The gas, which is sent to a treatment facility, contains 92.0 %(v/v) HCl and 8 % unreacted chlorine. Assume ideal-gas behavior. Volume of Gas Check stoichiometry and gas behavior. What volume of gas leaves the reactor (m³) per kg B fed? i ! m3arrow_forward

- 8.2 L of chlorine gas at 298 K and 3.0 atm is added to a rigid 4.0 L reaction vessel containing 3.2 moles of He gas and 2.4 moles of fluorine gas? Chlorine and Fluorine gas react according to the following reaction at 298 K. Cl2 (g) + 3 F2 (g) à 2 ClF3 (g) What is the partial pressure of ClF3 after the reaction is complete? If the reaction proceeded with a percent yield of 40%, what would be the partial pressure of ClF3?arrow_forwardThe reaction of carbon monoxide(g) with water(l) to form carbon dioxide(g) and hydrogen(g) proceeds as follows: CO(g) + H2O(l) ---> CO2(g) + H2(g) When 10.2 grams of CO(g) react with sufficient H2O(l) , 1.02 kJ of energy are absorbed .What is the value of H for the chemical equation given?arrow_forwardPlease note when values are sourced from an appendix/table. Include any assumptions.arrow_forward

- The vapor leaving the top of a distillation column goes to a condenser in which either total or partial condensation takes place. If a total condenser is used, a portion of the condensate is returned to the top of the column as refcr and the remaining liquid is taken off as the overhead product (or distillate). If a partial condenser is used, the liquid condensate is returned as reflux and the uncondensed vapor is taken off as the overhead product. The overhead product from an n-butane-n-pentane distillation column is 93 mole% butane. The temperature of the cooling fluid limits the condenser temperature to 39 °C or higher. REFLUX DRUM a) Using Raoult's law, estimate the minimum pressure at which the condenser can operate as a partial condenser (i.e., at which it can produce liquid for reflux) b) The production rate of overhead product is 50 kmol/h, and the mole ratio of reflux to overhead product is 2:1. Calculate the molar flow rates and compositions of the reflux stream and the vapor…arrow_forwardA batch process is operated with the following sequence. The feed to the batch process consists of a solution of 500 L of ethanol with 120 mole of A and 120 mole of B. If the temperature of the solution is sufficient, A and B will react to form P (the desired product): A (eth) + B (eth) → P (s) DHreact = − 250 kJ/mol (1) product P is sparingly soluble in ethanol, which helps facilitate its removal from the reaction solution. It can be assumed that the reaction rate is first-order in both the concentration of A (cA ) and B (cB ), and so second-order overall: -r A = k c A cB (2) The batch process consists of the following FOUR steps: Initially, the tank is empty. 1. Fill tank with solution (ethanol/A/B). 50°C (1 hour) Increase temperature of the feed from 20°C to 2. Reaction takes place isothermally at 50°C (4 hours, to give conversion of 50%) 3. Filtration of reaction solution to give product P (2 hours) 4. Drying with hot nitrogen gas followed by the removal of powder product (3…arrow_forwardA liquid is fed to a distillation column at 4 atm absolute pressure. Its composition as a mole fraction is: n-butane: 0.40, n-pentane: 0.25, n-hexane: 0.20, n-heptane: 0.15. Using the equilibrium distribution coefficients (K), find the temperature at which this liquid will begin to boil (bubble temperature). Calculate the concentration of the first vapor bubble formed.arrow_forward

- Acetylene is produced from methane in the following reaction 2CH. (g) → C₂H₂(g) + 3H₂(g) An undesired side reaction is the decomposition of acetylene C₂H₂ (g) →2C₂(c) + H₂(g) Methane at 1000° C is fed to the reactor at a rate of 10 mol/s. The reactor operates isothermally at 1000° C. a. The fractional conversion of methane is 0.60 and the molar ratio of acetylene produced to methane consumed is 0.417. Calculate the rate of heat transfer (in kW) from/to the reactor. (Q= + 1100 kW) b. Calculate the rate of heat transfer (in kW) from/to the reactor if no side reaction occurs and the reaction goes to completion. 1819I ||arrow_forwardDO NOT SOLVE PROBLEM. Please just calculate extent of reaction and flow rates of each component in the reaction.arrow_forwardA chemical engineer is studying the following reaction: BF 3(aq)+NH3(aq) → BF ,NH3(aq) At the temperature the engineer picks, the equilibrium constant K for this reaction is 1.3. The engineer charges ("fills") three reaction vessels with boron trifluoride and ammonia, and lets the reaction begin. He then measures the composition of the mixture inside each vessel from time to time. His first set of measurements are shown in the table below. Predict the changes in the compositions the engineer should expect next time he measures the compositions. reaction expected change in concentration compound concentration vessel BE3 I decrease (no change) 0.48 M f increase NH3 I decrease (no change) 0.55 M f increase A BF,NH3 f increase I decrease (no change) 1.01 M 0.41 M f increase I decrease (no change) BF, NH3 I decrease (no change) 0.48 M f increase В BF,NH3 f increase I decrease (no change) 1.08 M BF3 I decrease (no change) 1.07 M ↑ increase NH3 I decrease (no change) 1.14 M f increase C…arrow_forward

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The