Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

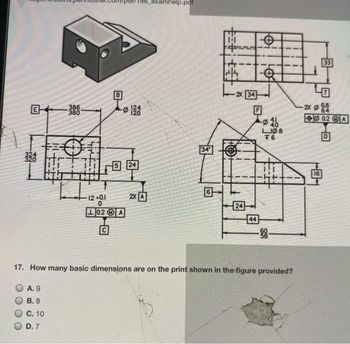

How many basic dimensions are on the print shown in the figure provided?

Transcribed Image Text:W

TIT-

A. 9

B. 8

C. 10

D. 7

B

d/186_examhelp.pdf

-Ø 120

12 +0.1

0

102A

G

24

2X A

34

11

Th

th

-2x 34

24

44

℗

-Ø 41

40

LJØ8

76

-88-

17. How many basic dimensions are on the print shown in the figure provided?

40

16

02 A

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Using the diagram, determine the minimum diameter for DIA B, in inches. Tin la Gallery 1 H DIAA 00000" 00016 BASIC DIMENSIONS DIA A 14230 DIA E# 14208 DIA B 00016 0.0000arrow_forwardWhat a linear distance would be shown on a drawing if the following dimensions are drawn to the scale sizes 2”arrow_forwardRequired information Sally is making a sine bar, which is used to machine angles on parts (see the given figure). She has a 1.250-inch-thick bar that needs 90° grooves machined into it for precision ground 1.0000-inch diameter cylinders. A sine bar is used by placing different thicknesses under one of the cylinders so that the proper angle is attained. Sally wants the distance between the centers of the cylinders to be D= 5.4 inches. -D -1.0000 Ø How deep should she mill the 90° grooves so that the top of the sine block is 2 inches tall? The depth of the mill should be inches.arrow_forward

- Q1: Use scale (1:1), draw the front, top & side views of shape shown below. (50 M) 15 20 60 15 45 30 2 HOLES DIA 20 120 30 15 60 F/ 35arrow_forwardPlease do not make any mistakes here. Important questionarrow_forwardQuestion 5 Assuming there is no wheel slippage, what is the wheel rotation speed in revolutions per minute of a car moving in a straight line at constant speed for 5 min over a distance of 181 m? The wheels have a diameter of 450 mm. Give your answer in meters rounded to two decimal places, use PI = 3.14. Do not write the unit in your answer.arrow_forward

- SPECIFY WHERE DIMENSIONS NEED TO BE PLACED FOR THE FOLLOWING PART NOTE: JUST NOTE WHERE DIMENSIONS NEED TO BE PLACED, NO NEED TO PUT THE ACTUAL NUMERICAL VALUES JUST USE LETTERING A, B, C, ETC.arrow_forward1.During a refrigerant system performance test the following results are recorded: outside ambient temperature of 908F, high-side gauge reading of 145 psi, and low pressure gauge reading of 14 psi. What is indicated by these results? A. Faulty refrigerant compressor B. Normal refrigerant system operation C. Low refrigerant levels D. A restriction on the high side of the refrigerant system 2. A customer complains of poor air-conditioning cooling performance. During a system performance test, the low-side gauge reading is 50 psig; the high-side gauge reading is 310 psig; and the ambient air temperature is 818F (27.228C). What is the least likely cause of the above results? A. Restricted airflow through condenser B. Refrigerant overcharge C. Refrigerant undercharge D. Overcharge of refrigerant oil I NEED BOTH QUESTION TYPED ANSWER PLEASE DETAIL ANSWERarrow_forwardRequired information Sally is making a sine bar, which is used to machine angles on parts (see the given figure). She has a 1.250-inch-thick bar that needs 90° grooves machined into it for precision ground 1.0000-inch diameter cylinders. A sine bar is used by placing different thicknesses under one of the cylinders so that the proper angle is attained. Sally wants the distance between the centers of the cylinders to be D= 5.9 inches. NOTE: This is a multi-part question. Once an answer is submitted, you will be unable to return to this part. 7 -1.00000 * How deep should she mill the 90° grooves so that the top of the sine block is 2 inches tall? (Round the final answer to four decimal places.) The depth of the mill should be 7071.067 inches.arrow_forward

- Please help. I need help with all 4 questions. Apply geometric tolerancing to part according to the instructions below. This exercise will provide you with experience in correctly applying and interpreting geometric tolerancing symbology. If you have trouble applying the symbols, page through this unit looking for similar examples. The Hole Bar in this unit is a good reference. Draw symbols and feature control frames clearly and neatly. 1. Establish all necessary basic dimensions. 2. Position the .250 hole within a diameter of .005 RFS relative to datum features A,B,C. 3. Position the three holes within a diamter of .012 at MMC relative to datum features A,B,C. 4. In the front view, identify the upper right corner as point "Y" and the lower left corner as point "X". Apply a profile tolerance of .020 between points X and Y relative to datum features A,B,C. Please refer to the attached image.arrow_forwardSelect the correct statement regarding the solid model shown below. pattern1 It is easiest to create the 18 holes in this model by sketching each individual hole and using the extruded boss/base feature. It is easiest to create the 18 holes in this model by sketching one individual holearrow_forwardHow would you determine final dimensions using the plus & minus method for question #D??arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY