Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

I want a solution to this question please

Transcribed Image Text:Home work

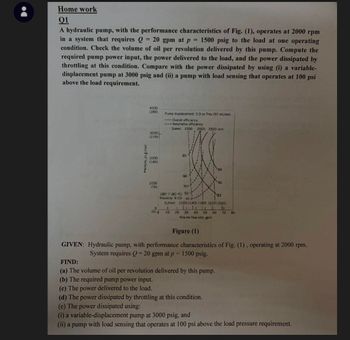

01

A hydraulic pump, with the performance characteristics of Fig. (1), operates at 2000 rpm

in a system that requires Q = 20 gpm at p = 1500 psig to the load at one operating

condition. Check the volume of oil per revolution delivered by this pump. Compute the

required pump power input, the power delivered to the load, and the power dissipated by

throttling at this condition. Compare with the power dissipated by using (i) a variable-

displacement pump at 3000 psig and (ii) a pump with load sensing that operates at 100 psi

above the load requirement.

4000

(280)

Pump displacement: 5.9 in.rev (97 mL/rev

-Overall efficiency

---Valumetric efficiency

Speed: 1500 2000 2500 1pm

3000 L

(210)

85

2000

(140)

1000

(70)

85

88

86

90-

180 F (80-C) 92-

83

Viscosity 9 cSt 97--

(U/min) (100) (140) (180) 1220) (260)

0

(0) 0

10

20 30 40 50 60 70 BO

Volume flow rate, gom

Figure (1)

GIVEN: Hydraulic pump, with performance characteristics of Fig. (1), operating at 2000 rpm.

FIND:

System requires Q = 20 gpm at p = 1500 psig.

(a) The volume of oil per revolution delivered by this pump.

(b) The required pump power input.

(c) The power delivered to the load.

(d) The power dissipated by throttling at this condition.

(e) The power dissipated using:

(i) a variable-displacement pump at 3000 psig, and

(ii) a pump with load sensing that operates at 100 psi above the load pressure requirement.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps with 1 images

Knowledge Booster

Similar questions

- A single stage centrifugal pump has an impeller of 250 mm diameter which rotates at 1,800 rpm and lifts 60 lit/sec to 25 m with an efficiency of 70%. Obtain the number of stages and diameter of each impeller of a similar multi-stage pump to lift 75 lit/sec to 175 m at 1,500 rpm. (8 stages ; 280 mm dia)arrow_forward6arrow_forwardProblem-4: The characteristics for a pump are given in the table below. The pump is required to left water against static head Az = EN" m. The pipe arrangement has a total length L the pump discharge, head, efficiency and power for the given pipe system. 200, d = 0.1 m and f= 0.016. Find %3D Q (L/s) 10 20 30 35 42 50 Hp (m) efficiency % 210 201 180 150 129 93 48 30 58 80 85 86 74 EN=62 Hp = Az + h, = Az + 12.1 d P = 757arrow_forward

- Figure below shows the performance curve family of Model 5009 Centrifugal pumps of Taco Pump Inc., running at a fixed speed of N = 1160 rpm. For the pump with the impeller diameter D = 8.625 in., calculate the power coefficient (Cp*) of the given pump at BEP if water is the fluid. HEAD IN FEET 0000 50 40 20 10 8.625" 30 (219mm). 0 O 0.821 O 0.731 O 0.467 aco 10 O 0.235 L/SEC 5 9.25" (235mm) 8.00" (203mm) 7.375" (187mm) 6.75" (171mm) 125 Model 5009 FI & CI Series 25 15 20 -do CURVES BASED ON CLEAR WATER WITH SPECIFIC GRAVITY OF 1.0 72% 75% 30 79% 1160 RPM FEBRUARY 19. 2002 40 3,5 45 REQUIRED NPSH 1.5HP (1.1KW) 79% 1⁰⁰ of 15² Curve no. 2140 Min. Imp. Dia. 6.75" Size 6 x 5 x 9.0 50 55 60 250 375 500 625 FLOW IN GALLONS PER MINUTE 72% 2HP(1.5KW) colo & 2⁰. It & SC- 09. 55% 5% 3HP (2.2KW) 7.5HP(5.6KW) 45% de 750 875 NGFEET 15 12 -9 -6 3 0 10 8 50 SHP(3.7KW) NPSH HEAD IN METERS 1000 r45 36 F27 18 -9 0 -100 --80 4 -40 -60 2 -20 -O HEAD IN KILOPASCALSarrow_forwardA centrifugal pump equipped with a variable frequency (speed) drive running at 3500 rpm is discharging 240GPM corresponding to a head of 287ft. The horsepower is 35.5. if the pump's speed is reduced to 2900 rpm, what will be the revised flow rate? Select the correct response: 176.21 gpm 76.21 gpm 89.66 gpm 98.85 gpm 289.66 gpm 198.86 gpmarrow_forwardA prototype pump is designed to so that the attached dimensionless performance curves apply. (a) If the pump is powered by a fixed speed motor delivering a rotational speed of 400 rpm and the impeller diameter is 2 m find the unknown quantities (Q, H, P,n ). Assume the pump is operating a peak efficiency and is pumping cold water. (b) If the pump is to be connected to standard steel pipe, which pipe should be used. Сн 1.00 Efficiency-n 0.75 CH 3 0.50 0.25 0.04 0.08 0.12 0.16 Ce C, and Efficiencyarrow_forward

- This course EHide block A centrifugal pump with the following impeller dimensions is used to pump water. The pump is running at 1000 rpm. The ideal head rise through the pump is 190 ft. b2 Poz 72 by The parameters of the impeller are as follows: r2= 9in, b2=3in, B2= 31° Take g= 9.81 m/s23 32.2 ft/s2 pw = 998 kg/m3 = 1.94 Slug/ft. Determine the theoretical flow rate in gpm Choose.. Determine the theoretical Power shaft in (hP) Choose...arrow_forwardDisplacement (c): 0.2 in3/revShank diameter (d) = 0.625 in.Piston diameter (D) = 1.5 in.Rotation speed (n): 1725 RPMPressure (P): 600 PSIStroke (L) = 18in. a) Calculate the theoretical flow rate of the pump in in3/min and US GPM.Theoretical flow (Q) = Theoretical displacement (C) x Speed of revolution (n)Theoretical flow (Q) = 0.2 in3/rev x 1725 rpmTheoretical flow (Q) = 345 in3/min = 1.49 US GPM b) Calculate the cylinder output speed in in/s.Cylinder output speed (VS) = Piston side flow (Q) / Piston area (Ap)Cylinder output speed (VS) = (Displacement x Speed of revolution) / Piston area (Ap)Cylinder output speed (VS) = (0.2 in3/rev x 1725 RPM) / 1.77 in2Cylinder output speed (VS) = (0.2 in3/rev x 1725 RPM) / 1.77 in2Cylinder output speed (VS) = 196.02in/s = 196.02 / 60s = 3.20 in/s Questions: c) Knowing the output velocity (ram speed), calculate the rod side flow in GPM when the ram is extending. d) Calculate the piston exit time in seconds. e) Calculate the piston entry time in…arrow_forwardProblem 5. Performance curves are available here at three different operating speeds, N = 1750, 2900, and 3500 rpm, for a family of stainless-steel pumps with closed impellers (SSPC1 250 Family) manufactured by American Stainless Pumps . (a) Make three tables (one for each N) at the best efficiency point, BEP, with the following columns: diameter, D (in), flowrate, Q (gpm), head, H₂ (ft), power, Wm (hp), efficiency, np, and specific speed in U.S. customary units, Ns,cu, and dimensionless, Ns. Use Web Plot Digitizer (the first 5 minutes of the tutorial video will show you how it works) to extract the data points for H₂ and at the BEP. (b) Use the scaling laws to produce the same table at N = 2900 rpm from the data at N = 3500 rpm. Briefly discuss the agreement between these two tables. (c) Plot N, versus D for all three values of N on the same figure. Briefly discuss the agreement of the curves.arrow_forward

- A large centrifugal pump has a 254 mm diameter inlet and a 127 mm diameter outlet pipe. Themeasured flow rate is 51.6 Liter per second of cold water. The measured inlet pressure is 127 mmHg above atmospheric and discharge pressure measured at a point 1.22 m above the pump outletis 212 kPa absolute. The pump input is 10 Hp. Find the pump efficiencyarrow_forwardS 3arrow_forwardFind the specific speed of a double suction centrifugal pump delivering 1.5 m³/s against a net head of 15 m when running at 725 r.p.m. state the type of impeller to be employed for this pump.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY