Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

4-6

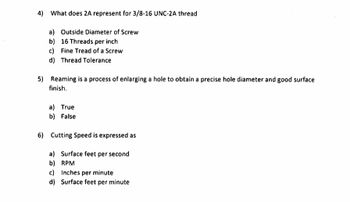

Transcribed Image Text:4) What does 2A represent for 3/8-16 UNC-2A thread

a) Outside Diameter of Screw

b) 16 Threads per inch

c) Fine Tread of a Screw

d) Thread Tolerance

5) Reaming is a process of enlarging a hole to obtain a precise hole diameter and good surface

finish.

a) True

b) False

6) Cutting Speed is expressed as

a) Surface feet per second

b)

RPM

c) Inches per minute

d) Surface feet per minute

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps

Knowledge Booster

Similar questions

- 2-Calculate a)Basic Size, b) Dmax , c) Dmin , d)dmax , e)dmin , f) All Clearances if any , and g) All interferences if any, for inch fit 07.09LN6S. If there is no an answer for a row leave it blank (show all calculations). a)Basic Size, and fit symbol b) Dmax c) Dmin » d)dmax , e)dmin , f) max and min Clearances if any, g) max and min interferences if any 3-Determine a)Basic Size, b) Dmax , c) Dmin , d)dmax, e)dmin , f) All Clearances if any, and g) All interferences if any, for inch fit 03.15LT6. If there is no an answer for a row leave it blank (show all calculations). a)Basic Size, and fit symbol b) Dmax » c) Dmin » d)dmax » e)dmin : f) max and min Clearances if any, g) max and min interferences if any 4-Determine f) All Clearances if any, and g) All interferences if a)Basic Size, b) Dmax , c) Dmin , d)dmax , e)dmin , any for metric fit 06.75 H7/n6. If there is no an answer for a row leave it blank • (show all calculations). a)Basic Size, and fit symbol b) Dmax » c) Dmin , d)dmax »…arrow_forwardIn drilling operations, the height of the generated hole constrained by: a) Cutting angle b) Shank length c) Body length d) Flute length e) Over all lengtharrow_forward5) Reaming is a process of enlarging a hole to obtain a precise hole diameter and good surface finish. a) True b) False 6) Cutting Speed is expressed as a) Surface feet per second b) RPM c) Inches per minute d) Surface feet per minute 7) Reaming is a process of a) Cutting threads in a Workpiece b) Making a precise hole in a Workpiece c) Making shape for a Socket flathead cap screw in a Workpiece d) Making shape for a Socket head cap screw in a Workpiece. 8) Tapping is a process of a) Cutting threads in a Workpiece b) Making precise hole in a Workpiece c) Making shape for a Socket Flathead cap screw in a workpiece d) Making shape for a Socket head cap screw in a Workpiecearrow_forward

- A constant angular velocity WAB= 16 rad's clockwise. At the instant when = 90°, a) The velocity of B and D. b) The angular velocity WAB c) The angular acceleration of the connecting rod BD. 50 mm 150 mmarrow_forward29) For the shaft and hole sizes shown in the figure, specify the type of fit. 5.000 4.997 5.012 5.008 a) Shaft a) Clearance Fit b) Interference Fit c) Transition Fit 30) The location of a hole may be controlled by what GD&T symbol? b) c) d) Z Hole d) Clean Fit 31) Based on "ANSI/third angle projection", the Top view is normally above which view? a) Right Side b) Front c) Left Side d) Back Page 3 32) When you position a hole on a part which tolerance method gives you more acceptable parts a) Coordinate Tolerancing b) CMM Tolerancing c) Baseline Tolerancing d) Functional Tolerancing 33) The symbol indicates what term? a) diameter b) hole center c) zero d) radius 34) Which dimensioning scheme is best to minimize issues with tolerance? b) GD&T c) Coordinate Positioning a) Chain d) Baseline Copyright Univeristy of Californiaarrow_forwardSpinning at 10.0 revolutions per second (rev/s). The diameter of the electric drill bit is 4.00 mm. What is the linear speed of a point on the surface of the drill bit, in meters per second? Show computations a) 0.126 m/sec b) 0.105 m/sec c) 0.150 m/sec d) 0.160 m/secarrow_forward

- system, the driver gear ear's axle by a certain small motor. Hand drills pm) are the number ocity ratio (VR) is abling гор task 2 Calculate mechanical advantage for gears using ratios n your own. rook at the gear train in Figure 15. Driver gear Teeth = 25 90 rpm ar the driver, the has 40 what is 04 cm 012 cm Driven gear Teeth = 75 2. d) b) a) Figure 15 Determine how many times the driven gear will rotate for every full rotation of the driver gear. Use the gear wheel diameter formula. Use the tooth ratio formula to calculate the gear ratio of the gear train. (3) Calculate the output speed of the driven gear. Look at the gear train in Figure 16. Calculate the velocity ratio of the driven gear. Calculate the velocity ratio in revolutions per minute at gear C. Driver gear Teeth = 15 Idler gear Teeth = 45 (4) (3) (3) (8) Figure 16 A B Driven gear Teeth = 5arrow_forwardNote: I need both answer with clear explanation. Don't copy from other expert answer Urgenttttttt pleasearrow_forwardSolve it correctly please. I will rate accordingly with 4votes.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY