Understanding Business

12th Edition

ISBN: 9781259929434

Author: William Nickels

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Question

Transcribed Image Text:܀

܀

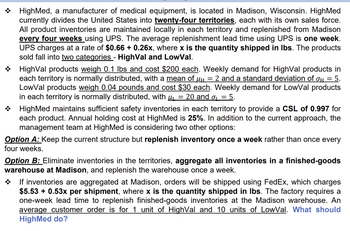

HighMed, a manufacturer of medical equipment, is located in Madison, Wisconsin. HighMed

currently divides the United States into twenty-four territories, each with its own sales force.

All product inventories are maintained locally in each territory and replenished from Madison

every four weeks using UPS. The average replenishment lead time using UPS is one week.

UPS charges at a rate of $0.66 + 0.26x, where x is the quantity shipped in lbs. The products

sold fall into two categories - HighVal and LowVal.

HighVal products weigh 0.1 lbs and cost $200 each. Weekly demand for HighVal products in

each territory is normally distributed, with a mean of μч = 2 and a standard deviation of σ = 5.

LowVal products weigh 0.04 pounds and cost $30 each. Weekly demand for LowVal products

in each territory is normally distributed, with µ = 20 and σ = 5.

HighMed maintains sufficient safety inventories in each territory to provide a CSL of 0.997 for

each product. Annual holding cost at HighMed is 25%. In addition to the current approach, the

management team at HighMed is considering two other options:

Option A: Keep the current structure but replenish inventory once a week rather than once every

four weeks.

Option B: Eliminate inventories in the territories, aggregate all inventories in a finished-goods

warehouse at Madison, and replenish the warehouse once a week.

܀

If inventories are aggregated at Madison, orders will be shipped using FedEx, which charges

$5.53 + 0.53x per shipment, where x is the quantity shipped in lbs. The factory requires a

one-week lead time to replenish finished-goods inventories at the Madison warehouse. An

average customer order is for 1 unit of HighVal and 10 units of LowVal. What should

HighMed do?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps

Knowledge Booster

Similar questions

- kaiarrow_forwardTyler decided to open a bakery because everyone he knew told him that his baked goods were "out of this world." He had a little bit of a business school background because he got his Bachelor's from SPS at UIW recently. He remembered his teacher telling him that inventory models can be used for both the raw materials as well as the finished products for a business like his. So, he decided to see if he could use the basic EOQ model for identifying how much quantity to order of raw materials such as eggs, flour, sugar, etc. To get started, he decided to create a model for flour based on the information he had on hand regarding potential costs as follows: Usage per month 100 Ibs Purchase cost $1 per Ib. Order cost $10.00 per order sent Annual Holding Rate 10% of purchase price per Ib. • 52-week year 300 working days per year • Lead time 2 days Fill in the following table based on this information: Optimal Inventory Policy Answer Type 7 Reorder Point r Ibs. 8 Number of Orders Per Year…arrow_forwardSKU One is sold at retail store for $8 per unit. SKU One has a weekly demand of 975 units with an average lead time of 5 weeks and a standard deviation of lead time of 2 weeks. Based on the information and a 95% service level, what is the reorder point for SKU One? please show work how to solvearrow_forward

- Peter operates an ice cream shop and needs to order milk from a dairy supplier. The average daily milk consumption is 9 gallons, and the standard deviation is 2 gallons. The delivery time is 3 days on average, with a standard deviation = 1 day. Peter can place an order at any time, and he decides the order quantity = 100 gallons. What is the reorder point if he wants to keep the 95% service level?arrow_forwardThe production order quantity for this problem is approximately 332 units. daily demand rate = 64; daily production rate = 100. What is the average inventory on - hand ( in other words - the inventory for which you are paying Holding Costs ) In this problem ?arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Understanding BusinessManagementISBN:9781259929434Author:William NickelsPublisher:McGraw-Hill Education

Understanding BusinessManagementISBN:9781259929434Author:William NickelsPublisher:McGraw-Hill Education Management (14th Edition)ManagementISBN:9780134527604Author:Stephen P. Robbins, Mary A. CoulterPublisher:PEARSON

Management (14th Edition)ManagementISBN:9780134527604Author:Stephen P. Robbins, Mary A. CoulterPublisher:PEARSON Spreadsheet Modeling & Decision Analysis: A Pract...ManagementISBN:9781305947412Author:Cliff RagsdalePublisher:Cengage Learning

Spreadsheet Modeling & Decision Analysis: A Pract...ManagementISBN:9781305947412Author:Cliff RagsdalePublisher:Cengage Learning Management Information Systems: Managing The Digi...ManagementISBN:9780135191798Author:Kenneth C. Laudon, Jane P. LaudonPublisher:PEARSON

Management Information Systems: Managing The Digi...ManagementISBN:9780135191798Author:Kenneth C. Laudon, Jane P. LaudonPublisher:PEARSON Business Essentials (12th Edition) (What's New in...ManagementISBN:9780134728391Author:Ronald J. Ebert, Ricky W. GriffinPublisher:PEARSON

Business Essentials (12th Edition) (What's New in...ManagementISBN:9780134728391Author:Ronald J. Ebert, Ricky W. GriffinPublisher:PEARSON Fundamentals of Management (10th Edition)ManagementISBN:9780134237473Author:Stephen P. Robbins, Mary A. Coulter, David A. De CenzoPublisher:PEARSON

Fundamentals of Management (10th Edition)ManagementISBN:9780134237473Author:Stephen P. Robbins, Mary A. Coulter, David A. De CenzoPublisher:PEARSON

Understanding Business

Management

ISBN:9781259929434

Author:William Nickels

Publisher:McGraw-Hill Education

Management (14th Edition)

Management

ISBN:9780134527604

Author:Stephen P. Robbins, Mary A. Coulter

Publisher:PEARSON

Spreadsheet Modeling & Decision Analysis: A Pract...

Management

ISBN:9781305947412

Author:Cliff Ragsdale

Publisher:Cengage Learning

Management Information Systems: Managing The Digi...

Management

ISBN:9780135191798

Author:Kenneth C. Laudon, Jane P. Laudon

Publisher:PEARSON

Business Essentials (12th Edition) (What's New in...

Management

ISBN:9780134728391

Author:Ronald J. Ebert, Ricky W. Griffin

Publisher:PEARSON

Fundamentals of Management (10th Edition)

Management

ISBN:9780134237473

Author:Stephen P. Robbins, Mary A. Coulter, David A. De Cenzo

Publisher:PEARSON