Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

Urgent plzz in 15 min

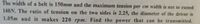

Transcribed Image Text:The width of a belt is 150mm and the maximum tension per cm width is not to exceed

140N. The ratio of tension on the two sides is 2.25, the diameter of the driver is

1.05m and it makes 220 rpm. Find the power that can be transmitted.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 3 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- I need the answer as soon as possiblearrow_forwardA pulley 610 mm diameter is driven at 300 revs/min by a belt, the tensions in the tight and slack sides of the belt being 670 N and 270 N. Find the power transmitted.arrow_forwardcalculate the power transmitted and the rotational speed in r/min of the small pulley of a belt drive where the diameter of the deriven pulley is 275 mm and rotates at 750 r/min. the driving pulley size is 125 mm. the tension is the tight side of the belt is 500 N, with the tension ratio between the tight and slack side side being 4.33:1arrow_forward

- Two pulleys, one 425mm diameter and the other 210mm diameter are one parallel shaft 2m apart and are connected by a crossed flat belt. Find the length of the belt required and the angle of conduct between the belt and each pulley. What power can be transmitted by the belt when the larger pulley rotates at 200 rev/min, if the maximum permissible tension in the belt is 1 kN, and the coefficient of friction between the belt and pulley is 0.3?arrow_forwardWith a driveshaft turning at 2000 rpm , I then have a spring that can rotate a shaft 5000 rpm, I want this spring to assist in the drive of the driveshaft, how can I express that or calculate the effect of adding the spring would make. Including a spring system alongside a driveshaft that can assist the drive up to 5000rpm, how can I integrate the spring system to assist in the driveshaft drive, calculations on the change in rotation the spring would have of the driveshaft speedarrow_forwardFind T.F to the mechanical system below? K 0000 S M Riyarrow_forward

- Theory of machinesarrow_forwardThe tensions in the tight and slack side of a belt drive system are 1850 N and 525 respectively. If the belt speed is 8 m/s what power in kW will be transmitted with no slippagearrow_forwardA flat belt type is used for a belt drive system connecting two pulleys 1.2m apart. The driver pulley with diameter 40 cm is rotating with the speed 350 rpm, while diameter of driven pulley is 100 cm. Coefficient of friction of the contact surface between belt and pulley is 0.3.Maximum allowable tension is 600N. (i) Find the power transmitted by the belt, P. (ii) Determine the Initial tension of the belt, TA. iii) If the flat belt is now replaced by a Vee-belt with groove angle of B = 300 , find the power transmitted by this belt. Give explanation why power transmitted by flat andVee-belt type are not the same. Explain your answer according to basic friction concept. iv) If a Vee-belt with groove angle of B = 900 is being used, find the power transmittedby this belt. Discuss your findings by comparing with answer in (i) and answer in (iii) above. (v) List and explain TWO (2) practical applications each for flat belt and Vee-belt drivearrow_forward

- A fixed angle rotor exhibits a minimum radius, rmin at the top of the centrifuge tube of 3 cm and a maximum radius rmax at the bottom of the tube of 9 cm. If the rotor is operated at a speed of 12 000 rpm, what is the relative centrifugal field, RCF at the top and bottom of the centrifuge tube?arrow_forwardComplete Solutionsarrow_forwardi need the answer quicklyarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY