Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

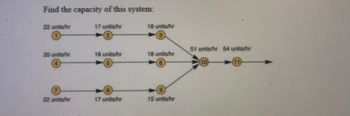

Transcribed Image Text:Find the capacity of this system:

22 units/hr

20 units/hr

22 units/hr

17 units/hr

18 units/hr

17 units/hr

18 units/hr

18 units/hr

6

15 units/hr

51 units/hr 54 units/hr

10

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 3 images

Knowledge Booster

Similar questions

- Lou operates a cab service specifically tailored to provide safe and comfortable transportation for seniors in his town. He owns five cabs, each staffed by a dedicated driver. Upon receiving a service call, Lou promptly dispatches one of these drivers to pick up the customer. The operational details are as follows: • Each driver takes an average of 15 minutes to arrive at the customer's location after being dispatched. • The journey from the customer's pickup location to their destination averages 25 minutes. • Lou’s service receives an average of 2.5 calls per hour. For analytical purposes, you can assume that both the arrival of service calls (demand) and the service times have coefficients of variation (CV) equal to 1. (a) What is the average waiting time for a customer from the moment they place a service call to Lou until a cab arrives to pick them up? (For answering this question carefully think about different stages of processes, and what a customer is doing in each stage. It…arrow_forwardStation 1 6 min/unit Station 2 Machine A 15 min/unit 6 minutes 20 minutes 91 minutes 226 minutes Station 2 Machine B 15 min/unit Station 3 10 min/unit Station 4 Machine A 60 min/unit Station 4 Machine B 60 min/unit Station 4 Machine C 60 min/unit A manufacturing plant has four stations in the assembly line (illustrated in the image above). A unit needs to be processed at either Machine A or Machine B for Station 2 (parallel lines, both lines performing the same operations). The box is then processed at Station 3. After that, the unit needs to be processed at either Machine A, Machine B or Machine C in Station 4 before leaving the production line. The process time of each station/machine is indicated in the flowchart. What is the process cycle time of this system measured in minutes?arrow_forwardA company operates 8 hours per shift, two shifts per day, five days a week with 12 hours maintenance per week and other downtime of 2 hours per week. What is the effective capacity in hours per week? Moving to thearrow_forward

- using spreadsheet models Using the Reciprocal Method allocate service centre costs Manufacturing $910,000 Assembly $175,000 Maintenance $472,000 Robotics $675,000 Department No. of Maintenance Jobs No. of Robotic Machines Manufacturing 265 16 Assembly 75 52 Maintenance 10 Robotics 28arrow_forwardIn the three-station process depicted in the figure below a product must go through one of the two machines at station 1 (they are parallel) before proceeding to station 2. (hr-hour, min-minutes) Capacity: 4 units/hr Station 1 Machine A Station 2 Station 3 Station 1 Machine B Capacity: Capacity: 12 units/hr 5 units/hr Capacity: 4 units/hr In one hour at most how many products the process can produce? O 5 units/hr 8 units/hr 12 units/hr O None of the abovearrow_forwardd CE Additional Algo 5-11 Attrition Losses and Yields A process has three resources and two types of flows. The first flow has a demand of 20 units per day, and the second flow has a demand of 40 units per day. The first flow type visits all three resources, while the second flow type only visits the first and the third resources. The capacity is 100 units per day at the first resource, 40 units per day at the second resource, and 70 units per day at the third resource. 1. What is the demand total for each resource? Note: Do not round intermediate calculations. Resource Resource 1 Resource 2 Resource 3 Resource Resource 1 Resource 2 Resource 3 Type 1 20 20 20 Implied Utilization Actual Flow Rate 1 Actual Flow Rate 2 Type 2 2. What is the implied utilization for each resource? Note: Round your answers to 2 decimal places. 40 TO 40 Demand Total 3. What is the actual flow rate for each flow? Note: Round your answers to 2 decimal places.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.