Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

Just need f.

|

Average weekly demand (52 weeks per year): |

71 printers |

|

|

Standard deviation of weekly demand: |

19 printers |

|

|

Order lead time: |

5 weeks |

|

|

Standard deviation of order lead time: |

0 (lead times are constant) |

|

|

Item cost: |

$170 per printer |

|

|

Cost to place an order: |

$5 |

|

|

Yearly holding cost per printer: |

$39 |

|

|

Desired service level during reordering period: |

95% (z=1.65) |

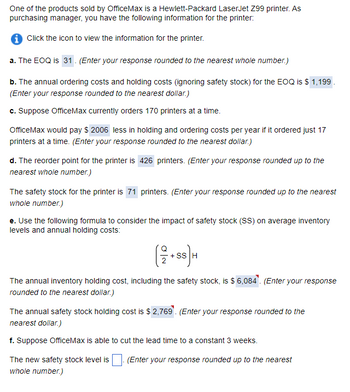

Transcribed Image Text:One of the products sold by OfficeMax is a Hewlett-Packard LaserJet Z99 printer. As

purchasing manager, you have the following information for the printer:

i Click the icon to view the information for the printer.

a. The EOQ is 31 (Enter your response rounded to the nearest whole number.)

b. The annual ordering costs and holding costs (ignoring safety stock) for the EOQ is $ 1,199.

(Enter your response rounded to the nearest dollar.)

c. Suppose OfficeMax currently orders 170 printers at a time.

OfficeMax would pay $ 2006 less in holding and ordering costs per year if it ordered just 17

printers at a time. (Enter your response rounded to the nearest dollar.)

d. The reorder point for the printer is 426 printers. (Enter your response rounded up to the

nearest whole number.)

The safety stock for the printer is 71 printers. (Enter your response rounded up to the nearest

whole number.)

e. Use the following formula to consider the impact of safety stock (SS) on average inventory

levels and annual holding costs:

(2 + SSH

The annual inventory holding cost, including the safety stock, is $6,084. (Enter your response

rounded to the nearest dollar.)

The annual safety stock holding cost is $ 2,769. (Enter your response rounded to the

nearest dollar.)

f. Suppose OfficeMax is able to cut the lead time to a constant 3 weeks.

The new safety stock level is

whole number.)

(Enter your response rounded up to the nearest

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps

Knowledge Booster

Similar questions

- Joe Henry's machine shop uses 2,450 brackets during the course of a year. These brackets are purchased from a supplier 90 miles away. The following information is known about the brackets: Annual demand 2,450 Holding cost per bracket per year $1.65 Order cost per order $18.50 Lead time 2 days Working days per year 250 a) What is the EOQ? __units (round your response to two decimal places). b) What is the average inventory if the EOQ is used?__ units (round your response to two decimal places). What would be the annual inventory holding cost? $__ (round your response to two decimal places). c) Given the EOQ, how many orders will be made annually?__orders (round your response to two decimal places). What would be the annual order cost? $__ (round your response to two decimal places). d) Given the EOQ, what is the total annual cost of managing (ordering and holding) the inventory? __ $ (round your response to two decimal places). d)…arrow_forwardK William Beville's computer training school, in Richmond, stocks workbooks with the following characteristics: Demand D 19,400 units/year Ordering cost S $27/order Holding cost H $5/unit/year a) The EOQ for the workbooks is 458 (round your response to the nearest whole number) b) What are the annual holding costs for the workbooks? $ (round your response to the nearest whole number).arrow_forward← William Beville's computer training school, in Richmond, stocks workbooks with the following characteristics: Demand D 19,400 units/year Ordering cost S $27/order Holding cost H $5/unit/year a) The EOQ for the workbooks is 458 (round your response to the nearest whole number). b) What are the annual holding costs for the workbooks? $ 1145 (round your response to the nearest whole number). c) What are the annual ordering costs? $ (round your response to the nearest whole number).arrow_forward

- Joe Henry's machine shop uses 2,460 brackets during the course of a year. These brackets are purchased from a supplier 90 miles away. The following information is known about the brackets: Annual demand 2,460 Holding cost per bracket per year $ 1.65 Order cost per order $20.00 Lead time 22 days Working days per year 250 a) What is the EOQ? b) What is the average inventory if the EOQ is used? What would be the annual inventory holding cost? c) Given the EOQ, how many orders would be made each year? What would be the annual order cost? d) Given the EOQ, what is the total annual cost of managing (ordering and holding) the inventory? e) What is the time between orders? f) What is the reorder point (ROP)?arrow_forwardDaily demand (d) 150 units Mean lead time (LT) 9 days Standard deviation of lead time (σLT) 3 days Service level 97% 1. What is the required safety stock at a 97 percent service level? ______ units 2. What is the reorder point? ______ unitsarrow_forwardSubject: Logistic management The following information is given to you D = 19,000 units/yr; H = $4/unit/year; S=$25/order. Calculate the EOQ, Annual holding cost and annual ordering cost.arrow_forward

- If annual demand is 6,125 units, annual holding cost is $5 per unit, and setup cost per order is $50, what is the EOQ lot size?arrow_forwardMatthew Liotine's Dream Store sells water beds and assorted supplies. His best-selling bed has an annual demand of 405 units. Ordering cost is $38; holding cost is $5 per unit per year. a) To minimize the total cost, how many units should be ordered each time an order is placed? EOQ = units (round your response to the nearest whole number). b) If the holding cost per unit was $6.00 instead of $5, what would the optimal order quantity be? New EOQ = units (round your response to the nearest whole number). Aarrow_forwardAnnual demand (D) is 49,000 units. Ordering Cost (S) is $1,000 per order. Holding cost (H) is $2 per unit per year. Find economic order quantity (Q*). 7,000 units 49,000,000 units 4,950 units 3,500 units 4,083 unitsarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.