Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

Transcribed Image Text:ECUR

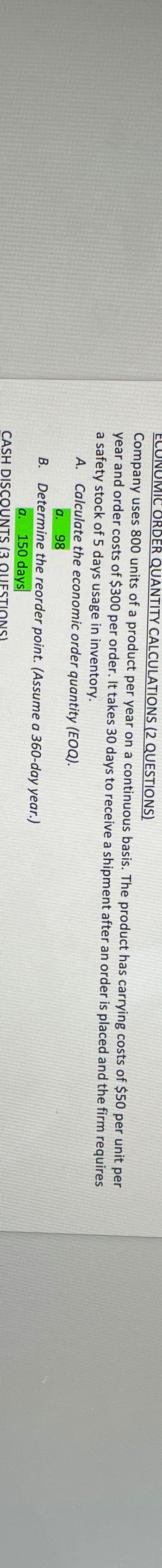

UMIC ORDER QUANTITY CALCULATIONS (2 QUESTIONS)

Company uses 800 units of a product per year on a continuous basis. The product

year and order costs of $300 per order. It takes 30 days to receive a shipment after an order is placed and the

a safety stock of 5 days usage in inventory.

has carrying costs of $50

A. Calculate the economic order

quantity

a. 98

B. Determine the reorder

a. 150 days

(3

CASH DISCOUNTS

point.

ONS)

(Assume

(EOQ).

a 360-day year.)

per

unit per

firm requires

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 4 steps with 9 images

Knowledge Booster

Similar questions

- Based on available information, lead time demand for PC jump drives averages 50 units (normally distributed), with a standard deviation of 5 drives. Management wants a 98% service level. Refer to the standard normal table for z-values. Part 2 a) What value of Z should be applied? ▼ 1.28? 2.06? 1.04? or 1.65? Part 3 b) How many drives should be carried as safety stock? ___________ units (round your response to the nearest whole number). Part 4 c) What is the appropriate reorder point? _________ units (round your response to the nearest whole number).arrow_forward*Note: "11102" has been attempted and is not the correct answer to this problem.arrow_forwardOne of the items you and your MBA buddie produce in your new business is sambocade cheesecake wild cherry based on an ancient recipe. One of the ingredients, we will call it açúcar, is the major component in the mixture. The demand for this item is very stable at 120 bags a day. However, the delivery lead times vary and has an average of 8 days and a standard deviation of two days. Tina, your other MBA buddie, suggested a 95% (Z = 1.65) service level for this product. What would be the appropriate reorder point for this item? 2,160 1,356 1,044 1,060 960 396 Not possible to calculate o o o o oarrow_forward

- Wear A Mask (WAM) uses a continuous review system and operates 52 weeks per year with the following characteristics: Demand (d) = 52,505 units/week Ordering cost (S) = $55.00/order Holding cost (H) = $2.50/unit/year ■ Lead time (L) = 3 week(s) Cycle-service level = 90%, z = 1.28 ▪ Demand is normally distributed, with a standard deviation of weekly demand of 103 units. ■ ▪ Current on-hand inventory is 1,040 units, with no scheduled receipts and no backorders. What is the optimal order quantity? (Enter your response rounded to nearest whole number.)arrow_forwardInventory Control – Definitions, Objectives and Activitiesarrow_forwardSunrise Garden Center buys 425 bags of fertilizer per month for feeding and weeding lawns. The ordering cost is $15.00. Holding cost is $0.10 per bag per year. a. How many bags should Sunrise order at a time? Sunrise should order bags at a time. (Enter your response rounded to the nearest whole number.) b. What is the time between orders? The time between orders is months. (Enter your response rounded to one decimal place.)arrow_forward

- 10.5 An SKU has an annual demand of 10,000 units, each costing $20, ordering costs are $80 per order, and the cost of carrying inventory is 25%. Calculate the EOQ in units and then convert to dollars.arrow_forwardIf D = 7,800 per month, S = $46 per order, and H= $2.50 per unit per month, a) What is the economic order quantity? The EOQ is units (round your response to the nearest whole number).arrow_forwardUniversity of Florida football programs areprinted 1 week prior to each home game. Attendance averages90,000 screaming and loyal Gators fans, of whom two-thirdsusually buy the program, following a normal distribution, for$4 each. Unsold programs are sent to a recycling center thatpays only 10 cents per program. The standard deviation is5,000 programs, and the cost to print each program is $1.a) What is the cost of underestimating demand for eachprogram?b) What is the overage cost per program?c) How many programs should be ordered per game?d) What is the stockout risk for this order size?arrow_forward

- If no safety stock is required, what would the re-order point be?arrow_forward4) Rane Brake Linings gathered information for its brake lining components as presented in the table below. How would the firm classify these items according to an ABC classification system? Initial Information Part # Unit Cost Annual Demand 10 10 200 11 30 125 12 9 100 13 12 5000 14 50 195 15 6 300 16 100 70arrow_forward(1) An architect firm uses an average of 60 boxes of copier paper a day. The firm operates 280 days a year.Storage and handling costs for the paper are $30 a year per box, and its costs approximately $60 to orderand receive a shipment of paper.(a) What quantity order size would minimize the total annual inventory cost?________________________________________________________________________________(b) Determine the minimum total annual inventory cost.________________________________________________________________________________(c) The office manager is currently using an order size of 300 boxes. The partners of the firm expect theoffice to be managed "in a cost-efficient manner." Would you recommend the manager to use yourquantity from part (a) rather than 300 boxes? _______.Justify your answer (by determining the total annual inventory cost for 300 boxes):_____________________________________________________________________________arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.