Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

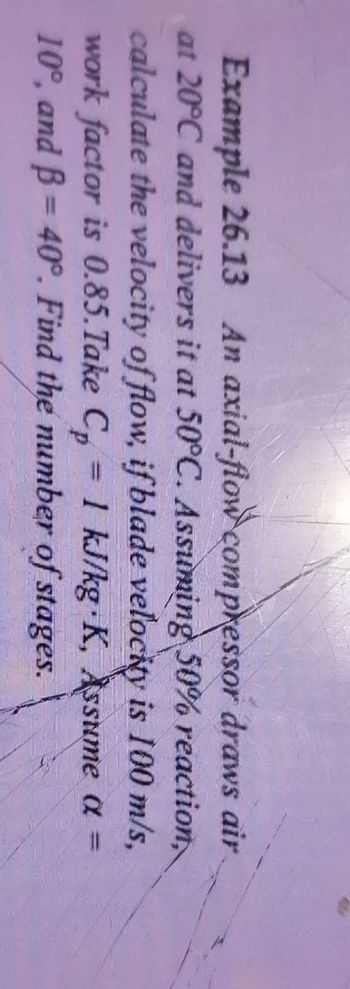

Transcribed Image Text:Example 26.13 An axial-flow compressor draws air

at 20°C and delivers it at 50°C. Assuming 50% reaction,

calculate the velocity of flow, if blade velocity is 100 m/s,

work factor is 0.85. Take Cp = 1 kJ/kg K, Assume a =

10°, and B = 40°. Find the number of stages.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps with 4 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Problem-5: In a CD nozzle with a throat area of 0.75 m² of a rocket engine, gas at 7.5 MPa and temperature of 3200 K is in combustion chamber, is expanded fully to (nozzle exit pressure) 10.5 kPa for producing thrust. Assuming flow to be frozen and isentropic, Also, Assume, gamma, y 1.2 and molecular weight, MW = 24 kg/kmol, Assume, universal gas = constant = 8314 J/Kg K mol Determine: (1) the exit Mach number, (2) the maximum exit mass flow rate passing through this nozzle, and (3) the exit area (4) If ambient pressure, i.e. pressure outside nozzle = 10.5 kPa, What is the thrust developed? Fuel Oxidant Combustion zone Mixture of Hot gas at high pressure and Temprature Expansion Through Nozzle High velocity exhaust Liquid Propellant Rocketarrow_forwardPlease don't provide handwritten solution ......arrow_forwardA The compression ratio of a diesel cycle is 15.5, and the cutoff occurs at 10% of the stroke. 14 psia and 600 K characterize state 1. Calculate the following for the hot-air standard with k= 1.34 and a starting volume of 2 cu ft: Qin a. Find T2 , P2 , V2 , T3 , V3 , P4 , and T4 3 P = P, b. Compute the heat added (QA), Wout heat rejected (Qr), work (W) and the cycle efficiency (e). P. c. for a rate of circulation of 1000 cfm, Qout compute the horsepower.arrow_forward

- Steam enters a control yolume that has one inlet and two exits. At the inlet (location 1) with a diámeterof 5.2 cm, the Steam has 100 bar , 360°C , and as mass flow rate of a Rg/sec. Through one exit (location 2), 15.% of the incoming mass flow rate Teaves the Control volume and the remainder leaves through the otner exit (locatión 3). For steady state opeaton, calculake the mass flow rate at locatlon 3 in kg/sec using 5 Signifigant figiures. रप्री दarrow_forwardThe last 3 parts B,D,Earrow_forwardPlease Fast.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY