Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN: 9781259696527

Author: J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Question

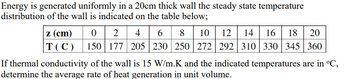

Transcribed Image Text:Energy is generated uniformly in a 20cm thick wall the steady state temperature

distribution of the wall is indicated on the table below;

z (cm)

T(C)

0

2 4 6 8 10 12 14 16 18 20

150 177 205 230 250 272 292 310 330 345 360

If thermal conductivity of the wall is 15 W/m.K and the indicated temperatures are in °C,

determine the average rate of heat generation in unit volume.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Similar questions

- Liquid food is heated in a tubular heat exchanger. The inner pipe wall temperature is 110 ° C. The internal diameter of the pipe is 40 mm. Product flows at 0.7 kg / s. If the initial temperature of the product is 7 ° C, calculate the convective heat transfer coefficient. The thermal properties of the product are as follows: specific heat = 3.7 kJ / (kg ° C), thermal conductivity = 0.6 W / (m ° C), product viscosity = 500 x 10-6 Pa s, density = 1000 kg / m³ , the product viscosity at 110 ° C = 410 x 10-6 Pa s. a. Find the Reynold number = Answer. b. Find the number Prantl = Answer. c. Find the Nuselt = Answer number d. Convection coefficient = AnswerW / m² ° C.arrow_forwardWhen a steel cookie sheet is placed in an oven and heated, it expands due the temperature change. The change in area of the cookie sheet is modeled using the following equation: AA = A,YAT where AA = change in area in in? Ao = original area in in y = area coefficient of thermal expansion AT = change in temperature in F° What is the appropriate unit for y if the preceding equation is to be homogeneous in units? O a. in? O b. F° O c. in O d. /°Farrow_forwardAnalyze the following diagram. What is the heat rate to the left side of the heater? What is the heat rate to the right side of the heater? Tin = 16°C W h = 40- T = -20°C u = 188 m2K 60mm Air 60mm 10mm 6mm 10mm 14mm 6mm 2mm 2mm Blue: Epoxy Grey: Aluminum Green: Fiberglass Yellow: Silicone Orange: Heater Blanket, 2000w Note: Treat the outer left wall as flat plates in external convection. Note: Ignore the thickness of the heater blanket.arrow_forward

- A 5-cm-diameter copper sphere is initially at a uniform temperature of 200◦C. Itis suddenly exposed to an environment at 20◦C having a heat-transfer coefficienth=28W/m2 · ◦C. Using the lumped-capacity method of analysis, calculate the timenecessary for the sphere temperature to reach 90◦C.arrow_forwardThe exhaust duct from a heater has an inside diameter of 114.3 mm with ceramic walls 6.4 mm thick. The average k=1.52 W/m· K. Outside this wall, an insulation or rock wool 102 mm thick is installed. The thermal conductivity of the rock wool is k= 0.046+ 1.56 x 104 T°C (W/m · K). The inside surface * = temperature of the ceramic is T1 = 588.7 K, and the outside surface temperature of the insulation is 311 K. Calculate the heat loss for 1.5 m of duct and the interface temperature T2 between the ceramic and the insulation. [Hint: The correct value of km for the insulation is that evaluated at the mean temperature of (T2 + T3)/2. Hence, for the first trial assume a mean temperature of, say, 448 K. Then calculate the heat loss and T2 Using this new T2, calculate a new mean temperature and proceed as before.]arrow_forward(a) What is the heat loss per unit length of the pipe?(b) The pipe material is switched to PTFE (k = 0.38 W/(m⋅K)). To maintain the same heat loss as theprevious question, if all other parameters are to remain the same as before, what is the required thicknessof the pipe wall in centimeters?arrow_forward

- À wall of area 30 m² having a density of 1500 kg/m', thermal conductivity 30 W/m.K, and specific heat capacity 4 kJ/kg.K. The temperature distribution across a wall 0.5 m thick at a certain instant of time is given as T(x) = 30-5 x-7x The wall is generating a uniform heat (q.) of 1000 W. (1) Find the rate of heat transfer entering and leaving the wall (in W). (2) Find rate of energy stored in Watt. (3) Find (dFT/dx²) (4) Derive the change in temperature with respect to time equation (time rate of temperature change)- remember to substitute the value of (d T/dx²) from (part 3) and values of all other properties into final equation. %3Darrow_forward.240mm steam main pipe, 210m long is covered with 50mm of high temperature insulation (k-0.092 W/m °C) and 40mm of low temperature insulation (k-0.062 W/m °C). The inner and the outer surface temperature as measured are 390 °C and 40 °C respectively. Calculate: 1- The total heat loss per hour. 2- The temperature between two layers of insulation.arrow_forwardA copper electric wire of radius R, = 1 mm is isolated by a layer of PVC so that the outer radius of the wire Rg = 2 mm, as shown in Figure below. The wire exchanges heat with the air at 20°C according to a heat transfer coefficient h=20 W/m2°c: Given that : k=copper electrical conductivity=4.0 × 1070hm-'m¯! kpvc= PVC thermal conductivity = 0.3- m°C kco = copper thermal conductivity = 100 m°C %3D (amp/m)² And that the electrical heating source is given by : S, amp²s /kgm³ If the temperature (T,) on the outer surface (r = RG) is 25°C, what is the electrical current C (amp) that passes through this wire? Dont forget to state your hypothesis clearly. Hi, Could you please tell me what the book's name is? Thank you!arrow_forward

- A large slab of aluminum has a thickness of 10 cm and is initially uniform in temperatureat 400◦C. It is then suddenly exposed to a convection environment at 90◦Cwith h=1400 W/m2 · ◦C. How long does it take the center to cool to 180◦C?arrow_forwardProblem 8. Energy is generated uniformly in a 20cm thick wall the steady state temperature distribution of the wall is indicated on the table below; z (cm) T (C) 8 10 12 14 16 18 20 0 2 4 6 150 177 205 230 250 272 292 310 330 345 360 If thermal conductivity of the wall is 15 W/m.K and the indicated temperatures are in °C, determine the average rate of heat generation in unit volume.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Introduction to Chemical Engineering Thermodynami...

Chemical Engineering

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind...

Chemical Engineering

ISBN:9781118431221

Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:WILEY

Elements of Chemical Reaction Engineering (5th Ed...

Chemical Engineering

ISBN:9780133887518

Author:H. Scott Fogler

Publisher:Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:9781285061238

Author:Lokensgard, Erik

Publisher:Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:9780072848236

Author:Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:McGraw-Hill Companies, The