Principles of Accounting Volume 2

19th Edition

ISBN: 9781947172609

Author: OpenStax

Publisher: OpenStax College

expand_more

expand_more

format_list_bulleted

Question

General Accounting question

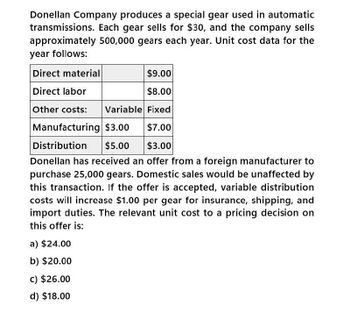

Transcribed Image Text:Donellan Company produces a special gear used in automatic

transmissions. Each gear sells for $30, and the company sells

approximately 500,000 gears each year. Unit cost data for the

year follows:

Direct material

Direct labor

$9.00

$8.00

Other costs: Variable Fixed

Manufacturing $3.00

$7.00

Distribution $5.00

$3.00

Donellan has received an offer from a foreign manufacturer to

purchase 25,000 gears. Domestic sales would be unaffected by

this transaction. If the offer is accepted, variable distribution

costs will increase $1.00 per gear for insurance, shipping, and

import duties. The relevant unit cost to a pricing decision on

this offer is:

a) $24.00

b) $20.00

c) $26.00

d) $18.00

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps

Knowledge Booster

Similar questions

- Hatch Manufacturing produces multiple machine parts. The theoretical cycle time for one of its products is 65 minutes per unit. The budgeted conversion costs for the manufacturing cell dedicated to the product are 12,960,000 per year. The total labor minutes available are 1,440,000. During the year, the cell was able to produce 0.6 units of the product per hour. Suppose also that production incentives exist to minimize unit product costs. Required: 1. Compute the theoretical conversion cost per unit. 2. Compute the applied conversion cost per minute (the amount of conversion cost actually assigned to the product). 3. Discuss how this approach to assigning conversion cost can improve delivery time performance. Explain how conversion cost acts as a performance driver for on-time deliveries.arrow_forwardGadubhaiarrow_forwardSpecter Company makes 20,000 units per year of a part it uses in the products it manufactures.The unit product cost of this part is computed as follows:Direct materials $25.10Direct labour 18.20Variable manufacturing overhead 2.40Fixed manufacturing overhead 13.40Unit product cost $56.70An outside supplier has offered to sell the company all these parts it needs for $56.00 a unit. Ifthe company accepts this offer, the facilities now being used to make the part could be used tomake more units of a product that is in high demand. The additional contribution margin on thisother product would be $50,000 per year.If the part were purchased from the outside supplier, all the direct labour cost of the part wouldbe avoided. However, $5.10 of the fixed manufacturing overhead cost being applied to the partwould continue even if the part were purchased from the outside supplier. This fixedmanufacturing overhead cost would be applied to the company's remaining products.Required:Part a:Calculate…arrow_forward

- Jordan Electronics currently produces the shipping containers it uses to deliver the electronics products it sells. The monthly cost of producing 9,100 containers follows. Unit-level materials Unit-level labor Unit-level overhead Product-level costs Allocated facility-level costs $ 5,700 6,800 3,900 8,100 27,200 One-third of these costs can be avoided by purchasing the containers. Russo Container Company has offered to sell comparable containers to Jordan for $2.90 each. Required a. Calculate the total relevant cost. Should Jordan continue to make the containers? b. Jordan could lease the space it currently uses in the manufacturing process. If leasing would produce $12.300 per rhonth, calculate the total avoidable costs. Should Jordan continue to make the containers? a. Total relevant cost Should Jordan continue to make the containers? b. Total avoidable cost Should Jordan continue to make the containers?arrow_forwardAdams Electronics currently produces the shipping containers it uses to deliver the electronics products it sells. The monthly cost of producing 9,300 containers follows. Unit-level materials Unit-level labor Unit-level overhead Product-level costs* Allocated facility-level costs $5,900 6,200 3,500 *One-third of these costs can be avoided by purchasing the containers. Russo Container Company has offered to sell comparable containers to Adams for $2.60 each. Required X Answer is complete but not entirely correct. $ 19,300 Yes $ 24,180 X No 11,100 26,900 a. Calculate the total relevant cost. Should Adams continue to make the containers? b. Adams could lease the space it currently uses in the manufacturing process. If leasing would produce $11,800 per month, calculate the total avoidable costs. Should Adams continue to make the containers? a. Total relevant cost a. Should Adams continue to make the containers? b. Total avoidable cost b. Should Adams continue to make the containers?arrow_forwardBaird Electronics currently produces the shipping containers it uses to deliver the electronics products it sells. The monthly cost of producing 9,100 containers follows. $ 6,500 6,400 4,100 9,600 27,900 Unit-level materials Unit-level labor Unit-level overhead Product-level costs* Allocated facility-level costs *One-third of these costs can be avoided by purchasing the containers. Russo Container Company has offered to sell comparable containers to Baird for $2.60 each. Required a. Calculate the total relevant cost. Should Baird continue to make the containers? b. Baird could lease the space it currently uses in the manufacturing process. If leasing would produce $11,200 per month, calculate the total avoidable costs. Should Baird continue to make the containers? a. Total relevant cost Should Baird continue to make the containers? b. Total avoidable cost Should Baird continue to make the containers?arrow_forward

- Perez Electronics currently produces the shipping containers it uses to deliver the electronics products it sells. The monthly cost of producing 9,300 containers follows. Unit-level materials $ 6,000 6,900 3,600 8,400 26,500 Unit-level labor Unit-level overhead Product-level costs* Allocated facility-level costs *One-third of these costs can be avoided by purchasing the containers. Russo Container Company has offered to sell comparable containers to Perez for $2.80 each. Required a. Calculate the total relevant cost. Should Perez continue to make the containers? b. Perez could lease the space it currently uses in the manufacturing process. If leasing would produce $12,800 per month, calculate the total avoidable costs. Should Perez continue to make the containers? a. Total relevant cost Should Perez continue to make the containers? b. Total avoidable cost Should Perez continue to make the containers?arrow_forwardGhuarrow_forwardThornton Electronics currently produces the shipping containers It uses to deliver the electronics products It sells. The monthly cost of producing 9,100 containers follows. Unit-level materials Unit-level labor Unit-level overhead Product-level costs* Allocated facility-level costs $ 5,100 6,400 3,300 9,900 28,000 *One-third of these costs can be avoided by purchasing the containers. Russo Container Company has offered to sell comparable containers to Thornton for $2.60 each. Required a. Calculate the total relevant cost. Should Thornton continue to make the containers? b. Thornton could lease the space it currently uses in the manufacturing process. If leasing would produce $12,100 per month, calculate the total avoidable costs. Should Thornton continue to make the containers? a. Total relevant cost a. Should Thornton continue to make the containers? b. Total avoidable cost b. Should Thornton continue to make the containers?arrow_forward

- Company XYZ is conducting an engineering economic analysis to decide whether to make vs purchase position for a necessary element needed ins several products. Now the engineering department has established this information: Option A to purchase 10,000 units annually at a fixed price of $8.50 per unit. The cost of placing the order is insignificant as per the present cost accounting procedure. Option B to manufacture 10,000 units annually with a direct labor cost of $1.50 per unit, manufacturing overhead cost is allotted at 200% of direct labor (which is $3.00 per unit) ) and Direct materials cost at $5.00 per unit. Based on the information, should the unit be purchased or manufactured?arrow_forwardRooney Electronics currently produces the shipping containers it uses to deliver the electronics products it sells. The monthly cost of producing 9,100 containers follows. Unit-level materials Unit-level labor Unit-level overhead Product-level costs* $ 5,200 6,500 3,600 9,300 26,600 Allocated facility-level costs *One-third of these costs can be avoided by purchasing the containers. Russo Container Company has offered to sell comparable containers to Rooney for $2.70 each. Required a. Calculate the total relevant cost. Should Rooney continue to make the containers? b. Rooney could lease the space it currently uses in the manufacturing process. If leasing would produce $11,500 per month, calculate the total avoidable costs. Should Rooney continue to make the containers? a. Total relevant cost Should Rooney continue to make the containers? b. Total avoidable cost Should Rooney continue to make the containers?arrow_forwardVishnuarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

- Principles of Accounting Volume 2AccountingISBN:9781947172609Author:OpenStaxPublisher:OpenStax College

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning

Principles of Accounting Volume 2

Accounting

ISBN:9781947172609

Author:OpenStax

Publisher:OpenStax College

Cornerstones of Cost Management (Cornerstones Ser...

Accounting

ISBN:9781305970663

Author:Don R. Hansen, Maryanne M. Mowen

Publisher:Cengage Learning