Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

Transcribed Image Text:=

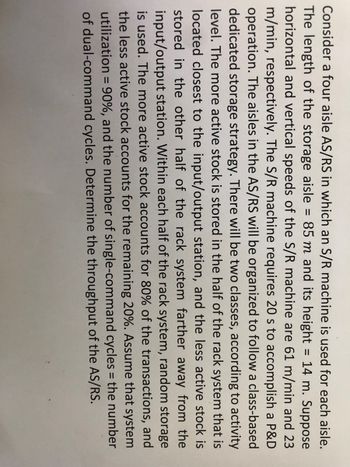

Consider a four aisle AS/RS in which an S/R machine is used for each aisle.

The length of the storage aisle 85 m and its height = 14 m. Suppose

horizontal and vertical speeds of the S/R machine are 61 m/min and 23

m/min, respectively. The S/R machine requires 20 s to accomplish a P&D

operation. The aisles in the AS/RS will be organized to follow a class-based

dedicated storage strategy. There will be two classes, according to activity

level. The more active stock is stored in the half of the rack system that is

located closest to the input/output station, and the less active stock is

stored in the other half of the rack system farther away from the

input/output station. Within each half of the rack system, random storage

is used. The more active stock accounts for 80% of the transactions, and

the less active stock accounts for the remaining 20%. Assume that system

utilization = 90%, and the number of single-command cycles = the number

of dual-command cycles. Determine the throughput of the AS/RS.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 3 steps with 4 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Direction: •Show unit cancellations and do not use shift solve.•Show your complete solution with this format: Given, Required, Solution. •Use 4 decimal place for answers. Question: A 6-stage-double-suction cetrifugal pump discharges 71 kg/s of oil (SG=0.75) at 1750 rpm with pressure drop of 525 psi. Find the specific speed in rpm. Subject: Fluid MachineriesCourse: Mechanical Engineeringarrow_forwardPlease don't provide handwritten solution .....arrow_forwardLet there be five jobs of the same type and one machine to get those jobs done. The processing time of the job on the machine and the time allowed for the job to be completed for each job are given in the table below. Job On the machinecompletion time(minute) Allowed To be finishedtime (minute) 1 3 4 2 6 8 3 8 12 4 4 15 5 2 11 Apply the branch-and-boundary method step by step to order the jobs in a way that minimizes the total delay time. State the optimal solution clearly. Thank you so much.arrow_forward

- Pls do it by steps and have procedure. Thankyouarrow_forwardQ:The Lift Mechanism for the package moving is desired to raise 25 inch in 2.50sec, remain stationery for 2.0 sec, and return in 2.0 sec. The push mechanism should remain stationery for 2.50 sec, push 25 inch in 2.0 sec and return in 2.0 sec. Determine (a) The Time Ratio, Cycle Time (b)Sketch the Synchronized time chartsarrow_forwardThe development of hybrid layout is possible with the identification of ________ Select one: a. Expected input b. Required output c. Part families d. Manager decisionsarrow_forward

- Given data: Initial velocity=5 m/s Final velocity=8 m/s Time=0.5 s Find accelerationarrow_forward4. Using below data for an army practice: A. Construct a project network B. Determine the length or exepected time of the project C. What is the Critical Path No Activity Predecessor Duration (day) 1 Develop plan 2 Move engineerng division 3 Advance cavalary scout 1 2 4 Army march 4 5 Build pontoon bridge 6 Cavalary Reconn 7 Plan Fortifications 8 Troops build 9 Artillery placement 10 Cavalary disrutption 11 Create Supply lines 12 Attack 2, 3 4 3 3 3 4,7 6,8 6,8 5 2 10,11 1arrow_forwardChapter 19, Problem 54P, part task bI think there is an error in part task b. It is not clear how to find the final expression for T_max.After it has been made clear that T_max = T_3, there is a description (See blue square in the attached picture part task b) which describes that an expression must substitute T_1, but the written expression applies to T_3?In the calculation after this, there is a sudden jump to the final expression for T_max. But it's not clear how I'm going to get to the final expression? (The orange square in the attached picture of part task b) I have includet pictures from: The task descriptions. Expert sulution to part task a, where we are given the expression, that is needet to solve part task b. And expert sulution to part task barrow_forward

- 10.4 A planned manufacturing system will have the layout pictured in Figure P10.4 and will use an automated guided vehicle system to move parts between stations in the layout. All work parts are loaded into the system at station 1, moved to one of three processing stations (2, 3, or 4), and then brought back to station 1 for unloading. Once loaded onto its AGV, each work part stays onboard the vehicle throughout its time in the manufacturing system. Load and unload times at station 1 are each 0.5 min. Processing times at the processing stations are 6.5 min at station 2, 8.0 min at station 3, and 9.5 min at station 4. Vehicle speed = 50 m>min. Assume that the traffic factor = 1.0 and vehicle availability = 100%. (a) Construct the from-to chart for distances. (b) Determine the maximum hourly production rate for each of the three processing stations, assuming that 15 sec will be lost between successive vehicles at each station; this is the time for the vehicle presently at the station…arrow_forwardDimensions: a. Can be placed only in model space b. Can be placed only in paper space c. Must be erased and redrawn if the model changes d. Are controlled by their associated dimension stylearrow_forwardDesign a Geneva Mechanism for an eight station automated tables. The indexer diameter is set to 36 in and the station cycle time is 40s. Show both the design drawing and calculationsarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY