Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

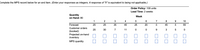

Transcribed Image Text:Complete the MPS record below for an end item. (Enter your responses as integers. A response of "0" is equivalent to being not applicable.)

Order Policy: 100 units

Lead Time: 2 weeks

Quantity

on Hand: 80

Week

1

2

3

4

5

6

7

8

9

10

Forecast

25

25

35

45

25

20

45

55

Customer orders

25

30

7

11

(booked)

Projected on-hand

inventory

MPS quantity

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 3 images

Knowledge Booster

Similar questions

- • What is the Reorder Point (ROP)? • What is the fill rate? What is the average inventory? • What is the average flow time? Given Data: Coefficient of variation (CV) = 0.24 Average weekly demand = 540 units Standard deviation = 130 units Lead time=2 Lot size = 1641 Safety inventory: NORMSINV(0.95) = 1.64 Standard deviation * sqrt(2) * 1.64 130*√√2*1.64 301.51 301 = 301 unitsarrow_forwardQUESTION 2 When used effectively, S&OP Planning does not require cross-functional collaboration. O True Falsearrow_forwardPlease do not give solution in image format thankuarrow_forward

- The president of Hill Enterprises, Terri Hill, projects the firm's aggregate demand requirements over the next 8 months as follows: 2,200 January 1,400 May February 1,600 June 2,200 March April 1,800 1,800 July August 1,800 1,400 Her operations manager is considering a new plan, which begins in January with 200 units of inventory on hand. Stockout cost of lost sales is $100 per unit. Inventory holding cost is $25 per unit per month. Ignore any idle-time costs. The plan is called plan C. Plan C: Keep a stable workforce by maintaining a constant production rate equal to the average gross requirements excluding initial inventory and allow varying inventory levels. Conduct your analysis for January through August.arrow_forwardpls some assistance :((arrow_forwardPlease do not give solution in image format thankuarrow_forward

- Please do not give solution in image format thankuarrow_forwardIn reference to the attached image: What would be the impact of a scheduled receipt of 200 units for item B in week 3 (and allother data remained the same) on your calculated planned order receipts and releases?arrow_forwardFlora’s Fabulous Fountains’ (FFF) top product is its ModelA. Using the information given, draw the product structure treefor the Model Aarrow_forward

- 2. Given the information below, complete the MRP record and explain what it tells the inventory analyst to do. Lot Size Rule: Fixed Q = 200 units Safety Stock: 0 units Lead Time = 2 weeks Current On-Hand Quantity = 100 units Week 1 2 3 4 7 8. Gross Requirement 50 100 60 00 50 90 200 Scheduled Receipts 200 Projected On Hand 100 Planned Receipts Planned Order Releasearrow_forwardQ7. The president of Rose Bowl Enterprises, Desmond Howard, projects the firms aggregate DEMAND requirements over the next 8 months as follows: These are the monthly DEMAND, not production. MONTH JAN FEB MAR APR MAY JUN JULY AUG DEMAND 1,400 1,600 1,800 1,800 2,200 2,200 1,800 1,800 PRODUCTION 1,600 from December INVENTORY 200 from Dec plus 200 His operations manager is considering a new plan, which begins in January with 200 units on hand. Stockout cost of lost sales is $100 per unit. Inventory holding cost is $20 per unit per month. Ignore any idle time costs. The plan is called plan A. Plan A: Vary the workforce level to execute a strategy that produces the quantity demanded in the prior month. The December demand was given as 1,600 units per month. Therefore, the production for JAN will be 1,600. However, only 1,400 are needed. Therefore, the extra 200 produced go into inventory and there is a holding cost for inventory. Also, per the above, you already have 200 units in inventory…arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.