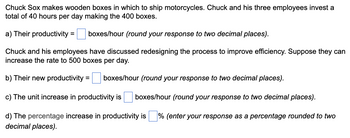

Chuck Sox makes wooden boxes in which to ship motorcycles. Chuck and his three employees invest a total of

40 hours per day making the

400 boxes.

Part 2

a) Their productivity =

enter your response here

boxes/hour (round your response to two decimal places).

Part 3

Chuck and his employees have discussed redesigning the process to improve efficiency. Suppose they can increase the rate to

500 boxes per day.

Part 4

b) Their new productivity =

enter your response here

boxes/hour (round your response to two decimal places).

Part 5

c) The unit increase in productivity is

enter your response here

boxes/hour (round your response to two decimal places).

Part 6

d) The percentage

LOADING...

increase in productivity is

enter your response here

% (enter your response as a percentage rounded to two decimal places).

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps

- Answer format: Number: Round to: 2 decimal places.arrow_forwardHow many workers are needed at each stage if management wants a utilization of at least 85 percent? Round your answers up to the nearest whole number. Stage A: __ workers Stage B: __ workers Stage C: __ workers Stage D: __ workers Stage E: __ workers Suppose that the number of workers at each stage are as follows: Stage Number of Workers A 5 B 3 C 7 D 5 E 2 What is the output rate at each stage? Round your answers to the nearest whole number. Stage A: __ units/hour Stage B: __ units/hour Stage C: __ units/hour Stage D: __ units/hour Stage E: __ units/hour Where is the bottleneck in this process? The bottleneck is (Stage A, B, C, D, or E).arrow_forwardGeorge Kyparisis makes bowling balls in his Miami plant. With recent increases in his costs, he has a newfound interest in efficiency. George is interested in determining the productivity of his organization. He would like to know if his organization is maintaining the manufacturing average of a 3% increase in productivity. He has the following data representing a month from last year and an equivalent month this year: Units Produced Labor (hours) Resin (pounds) Capital Invested ($) Energy (BTU) The percent change in productivity for one month last year versus one month this year or decimal places). Last Year 1,200 300 50 9,000 3,000 Now 1,200 275 45 10,000 2,850 Cost Per Input Unit $10 per hour $5 per pound 1% per month $0.50 per BTU multifactor basis with dollars as the common denominator = % (enter your response as a percentage rounded to twoarrow_forward

- If customer demand is 203,000 units per month, and available manufacturing capacity is 4,000 hours per week, what is the Takt time for this firm? (Round your answer to 2 decimal places.) Takt time hour/unitarrow_forwardThe following is given: Price $7.00/unit Variable cost $5.00/unit Fixed cost $50,000 a) Based on the given information, the break-even point in units = units (enter your response as a whole number). b) Based on the given information, the break-even point in dollars = $ (round your response to the nearest whole number). c) The profit for a volume of 80,000 units = $ (round your response to the nearest whole number).arrow_forwardCutie's Cruise Lines realized that they lose money every time they sail with even one empty cabin. The company VP of Operations has asked you, the company analyst, to calculate some metric to measure productivity for the last 5 sailings. Use the following data to determine your company's process yield as a percentage. Cabins Cabins Ship Available Occupied Anna 1940 2150 1860 Betty 2083 Charlie 1900 1810 Don 1930 1630 Eben 1310 1228 (Keep two decimal places in your answer) Your Answer: Answerarrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.