Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

Part a: Develop a spreadsheet model for calculating the optimal production plan for these three

products. Please adhere to the spreadsheet engineering principles and show all your work (formulas).

What is the optimal production plan to meet the demand?

Part b: Please comment on the marginal value (shadow price) of available hours for Machine 1

and Machine 2. If you have the opportunity to increase the capacity of one machine, which machine’s

capacity would you increase? By How much? How much benefit (cost reduction) this capacity change

would bring to C&D Inc.? Please explain in detail.

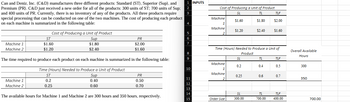

Transcribed Image Text:Can and Deniz, Inc. (C&D) manufactures three different products: Standard (ST), Superior (Sup), and

Premium (PR). C&D just received a new order for all of the products: 300 units of ST; 700 units of Sup;

and 400 units of PR. Currently, there is no inventory of any of the products. All three products require

special processing that can be conducted on one of the two machines. The cost of producing each product

on each machine is summarized in the following table:

3

1

INPUTS

2

Cost of Producing a Unit of Product

SL

TL

TLF

Machine

$1.60

$1.80

$2.00

4

1

Machine

$1.20

$2.40

$1.60

2

Cost of Producing a Unit of Product

ST

Machine 1

Machine 2

$1.60

$1.20

Sup

$1.80

$2.40

PR

$2.00

$1.60

569 %

7

Time (Hours) Needed to Produce a Unit of

Overall Available

8

Product

Hours

The time required to produce each product on each machine is summarized in the following table:

9

SL

TL

TLF

Machine

0.2

0.4

0.5

300

Time (Hours) Needed to Produce a Unit of Product

10

1

Machine

ST

Sup

PR

0.25

0.6 0.7

11

2

350

Machine 1

Machine 2

0.2

0.40

0.50

12

0.25

0.60

0.70

13

14

The available hours for Machine 1 and Machine 2 are 300 hours and 350 hours, respectively.

15

Order Size

SL

300.00

TL

700.00

TLF

400.00

700.00

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps

Knowledge Booster

Similar questions

- A plant operation has fixed cost of $2,000,000 per year, and its output capacity is 100,000 electrical appliances per year. The variable cost is $70 per unit, and the product sells for $120 per unit. a) What is the annual break even volume of this product? b) Compare annual profit when the plant is operating at 90% capacity with the plant operation at 100% capacity. Assume that the first 90% of capacity output is sold at $120 per unit and that the remaining 10% of production is sold at $100 per unit. Show handwritten solutionsarrow_forwardDemand for a product is forecasted for the six periods is 263, 256, 301, 312, 304, and 294 respectively. If a CHASE DEMAND strategy is adopted, and the regular production cost is RO 12 per unit with a maximum regular production of 280 units per period. While, the overtime and subcontract costs are RO 20 and RO 25 per unit respectively, There is no limit on subcontracting: however, maximum overtime production capacity is 10. Average inventory holding cost is RO 5 per unit per period. How many units in total are held as inventory? Select one Oa 40 Ob 51 Oco Od None is correct Oe. 1629arrow_forwardYou work for the Brad's Nailer Company which manufactures two types of nailers: a pneumatic model and a cordless model. You have contracted to supply a national retail chain with both pneumatic nailers and cordless nailers. However, Brad's nailer production capability is limited in three departments: production, testing, and packaging. Your answer will be the production hours needed to execute a production plan that minimizes costs - rounded to the nearest whole hour. (The number of nailers may not be a whole number, which is acceptable in this chapter.) Use Scenario 2 Pneum. Cost Pneum. Prod Hrs Pneum. Test Hrs Pneum. Pkg Hrs Pneum. Sales Cordless Cost Cordless Prod Hrs Cordless Test Hrs Cordless Pkg Hrs Cordless Sales Prod Hrs max Testing Hrs max Pkg Hrs max Scenario 1 Scenario 2 Scenario 3 52 0.2 0.3 0.1 22,000 67 0.3 0.4 0.1 15,500 10,000 15,000 4,800 55.50 0.4 0.3 0.1 24,500 69.75 0.3 0.5 0.1 15,500 20,000 18,000 4,200 38.50 0.25 0.4 0.1 18,000 44 0.4 0.4 0.2 14,000 20,000 18,000…arrow_forward

- Fitness Express sells three different types of elliptical machines. They have manufactured 50 of each machine for a special sale. The store already ha orders for 46 of machine A and 16 of machine B. Use the following information to determine how many of machine C the store needs to sell to break even? Show your work on a separate sheet of paper. Manufacturing Cost $105.00 $140.00 $175.00 Elliptical Machine Machine A Machine B Machine C Total costs of all machines: $ Total revenue: $ Number of machine Cs to sell to break even: Retail Cost $250.00 $305.00 $420.00arrow_forwardNeed all pleasearrow_forward4/Do not solve it in excel , please.arrow_forward

- Formulate the situation in matrix form. Be sure to indicate the meaning of your rows and columns. Find the requested quantities using the appropriate matrix arithmetic. A car dealer sells sedans, station wagons, vans, and pickup trucks at sales lots in Oakdale and Roanoke. The "dealer markup" is the difference between the sticker price and the dealer invoice price. The dealer invoice prices at both locations are the same: $15,000 per sedan, $19,000 per wagon, $24,000 per van, and $26,000 per pickup. The sticker prices at the Oakdale lot are $18,900 per sedan, $23,900 per wagon, $28,900 per van, and $28,900 per pickup, while at the Roanoke lot the sticker prices are $17,900 per sedan, $22,900 per wagon, $26,900 per van, and $30,900 per pickup. Represent these prices as a dealer invoice matrix D and a sticker price matrix S. Use these matrices to find the dealer markup matrix M for these vehicles at these sales lots. (Let row 1 represent the dealer in Oakdale and row 2 represent the…arrow_forwardPlease do not give solution in image format thankuarrow_forwardSuppose 100,000 lamps are to be manufactured annually. It costs $1 to store a lamp for 1 year, $500 to set up the factory to produce a batch of lamps and $5 to produce each lamp. A. If all lamps are produced in one batch find the total cost? B. If all lamps are produced in two batches of equal size, find the total cost? C. If the number of units in each batch is q, then how many batches are there? D. Find the number of lamps in each batch to minmize the total cost? E. What is the minimum cost? [ i need all answer i will upvote]arrow_forward

- A company possesses two manufacturing plants, each of which can produce three products, X, Y, and Z, from a common raw material. However, the proportion in which the products are produced differs in each plant, and so are plant's operating costs per hour. Data on production per hour and costs are given below, together with current orders in hand of each product. Products Operating cost per hour Y Plant A 4 9. Plant B 4 2 10 Orders on hand 50 24 60 Formulate the above as a linear programming problem. Find the number of production hours needed to fulfill the orders on hand at minimum cost using the using Big M method.arrow_forwardThe Ace Manufacturing Company has orders for three similar products. Product Min A s.t. B C 1 2 Machine 3 Three machines are available for the manufacturing operations. All three machines can produce all the products at the same production rate. However, due to varying defect percentages of each product on each machine, the unit costs of the products vary depending on the machine used. Machine capacities for the next week and the unit costs are shown below. A A LB B Ic C Product 4 2 3 Orders (units) Machine 1 Capacity Product A Orders Machine 2 Capacity Product B Orders Machine 3 Capacity Product C Orders 1,800 X20 for all i, j. 700 1,100 Capacity (units) 1,400 (a) Develop the linear programming formulation of this problem. (Let x₁ be the number of units of product A produced by XA1 machine 1, x,, be the number of units of product i produced by machine j, etc.) 1,500 1,000 1 Machine $1.00 $1.30 $1.10 2 $1.20 $1.40 $1.00 $0.90 $1.20 $1.20 3 (b) Solve the transportation model for the…arrow_forwardA company with a capacity of 3,000 units a month has fixed costs of P1,500 a month and labor costs of P10 a unit. Material costs are P5 per unit. The company has been producing at 80 percent of capacity and selling its product for P20. 1What would its net income be at 100 percent at capacity 1.2What would its net income be at 120 percent of capacity if it is assumed that 20 percent more products could be produced on overtime at an extra P3 labor cost per unit for all production above 100 percent?arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.