Managerial Accounting

15th Edition

ISBN: 9781337912020

Author: Carl Warren, Ph.d. Cma William B. Tayler

Publisher: South-Western College Pub

expand_more

expand_more

format_list_bulleted

Question

How to work this probl

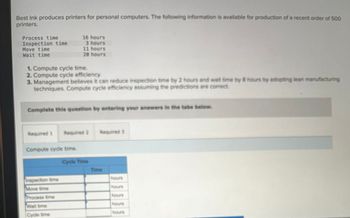

Transcribed Image Text:Best Ink produces printers for personal computers. The following information is available for production of a recent order of 500

printers.

Process time

16 hours

Inspection time

3 hours

11 hours

20 hours

Move time

Wait time

1. Compute cycle time.

2. Compute cycle efficiency.

3. Management believes it can reduce inspection time by 2 hours and wait time by 8 hours by adopting lean manufacturing

techniques. Compute cycle efficiency assuming the predictions are correct.

Complete this question by entering your answers in the tabs bellow.

Required 1 Required 2

Required 3

Compute cycle time.

Cycle Time

Time

Inspection time

hours

Move time

hours

Process time

Wait time

Cycle time

hours

hours

hours

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps

Knowledge Booster

Similar questions

- How do you solve thisarrow_forwardOakwood Company produces maple bookcases. The following information is available for the production of a recent order of 500 bookcases. Process time Inspection time Move time Wait time 1. Compute cycle time. 2. Compute cycle efficiency. 19 days 1 day 4 days 17 days 3. Management believes it can reduce move time by 1 day and wait time by 2 days by adopting lean manufacturing techniques. Compute cycle efficiency assuming the predictions are correct. Complete this question by entering your answers in the tabs below. Required 1 Required 2 Compute cycle time. Inspection time Move time Process time Wait time Cycle time Cycle Time Required 3 Time 0arrow_forwardBest Ink produces printers for personal computers. The following information is available for production of a recent order of 500 printers. Process time 16.0 hours Inspection time 3.5 hours Move time 9.0 hours Wait time 21.5 hours 1. Compute the company’s manufacturing cycle time. 2. Compute the company’s manufacturing cycle efficiency. 3. Assume the company wishes to increase its manufacturing cycle efficiency to 0.80. If process time is unchanged, what is the maximum number of hours of non-value-added time the company can have and meet this goal?arrow_forward

- Reduce setup time Vernon Inc. has analyzed the setup time on its computer-controlled lathe. The setup requires changing the type of fixture that holds a part. The average setup time has been 140 minutes, consisting of the following steps: a. Why should management be concerned about improving setup time? b. What do you recommend to Vernon Inc. for improving setup time? c. How much time would be required for a setup, using your suggestion in (b)?arrow_forwardBienestar, Inc., implemented cellular manufacturing as recommended by a consultant. The production flow improved dramatically. However, the company was still faced with the competitive need to improve its cycle time so that the production rate is one bottle every four minutes (15 bottles per hour). The cell structure is shown below; the times above the process represent the time required to process one unit. Required: 1. How many units can the cell produce per hour (on a continuous running basis)? 2. How long does it take the cell to produce one unit, assuming the cell is producing on a continuous basis? 3. What must happen so that the cell can produce one bottle every four minutes or 15 per hour, assuming the cell produces on a continuous basis?arrow_forwardNavern Corporation manufactures and sells custom home elevators. From the time an order is placed until the time the elevator is installed in the customer's home averages 82 days. This 82 days is spent as follows: Wait time Inspection time Process time Move time Queue time What is Navern's manufacturing cycle efficiency (MCE) for its elevators? Multiple Choice 41.5% 33.3% 58.5% 16 days 12 days 22 days 21 days 11 days 54.9%arrow_forward

- 46. Lorenzo corporation has provided the following data for one of its products. Process time = 3 days Queue time 4 days, Inspection time 0.7 days Move time 0.3 days Wait time 9 days The throughput time for this operation would be closest to Use the following information to answer 47 -50. Thomas Ito Manufacturing Corporation has the following information. Moving time 8 days, Inspection time 2 days, Processing time 10 days, storage time 30 days 47. The total amount of value added time would be: 48. The total amount of non-value added time would be 49. The product's cycle time would 50. The manufacturing cycle efficiency would bearrow_forwardShow me solutionarrow_forwardSolve this Accounting problemarrow_forward

- A month later, management estimate that if Aqua Marine implements the ERP sys a. $435,000 in software costs ERP system c. $105,000 for employee training The team estimates that the ERP system should provide several benefits: a. More efficient order processing should lead to savings of $105,000. b. Streamlining the manufacturing process so that it maps into the ERP system will cre- ate savings of $125,000. limie c. Integrating purchasing, production, marketing, and distribution into a single system will allow Aqua Marine to reduce inventories, saving $225,000. d. Higher customer satisfaction should increase sales, which, in turn, should increase profits by $155,000.arrow_forwardPlease do not give solution in image format ? And Fast answering please ? And Explain Proper Step by Step.arrow_forwardi want to this question answer General accounting questionarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Managerial AccountingAccountingISBN:9781337912020Author:Carl Warren, Ph.d. Cma William B. TaylerPublisher:South-Western College Pub

Managerial AccountingAccountingISBN:9781337912020Author:Carl Warren, Ph.d. Cma William B. TaylerPublisher:South-Western College Pub Financial And Managerial AccountingAccountingISBN:9781337902663Author:WARREN, Carl S.Publisher:Cengage Learning,

Financial And Managerial AccountingAccountingISBN:9781337902663Author:WARREN, Carl S.Publisher:Cengage Learning, Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning Managerial Accounting: The Cornerstone of Busines...AccountingISBN:9781337115773Author:Maryanne M. Mowen, Don R. Hansen, Dan L. HeitgerPublisher:Cengage Learning

Managerial Accounting: The Cornerstone of Busines...AccountingISBN:9781337115773Author:Maryanne M. Mowen, Don R. Hansen, Dan L. HeitgerPublisher:Cengage Learning Essentials of Business Analytics (MindTap Course ...StatisticsISBN:9781305627734Author:Jeffrey D. Camm, James J. Cochran, Michael J. Fry, Jeffrey W. Ohlmann, David R. AndersonPublisher:Cengage Learning

Essentials of Business Analytics (MindTap Course ...StatisticsISBN:9781305627734Author:Jeffrey D. Camm, James J. Cochran, Michael J. Fry, Jeffrey W. Ohlmann, David R. AndersonPublisher:Cengage Learning

Managerial Accounting

Accounting

ISBN:9781337912020

Author:Carl Warren, Ph.d. Cma William B. Tayler

Publisher:South-Western College Pub

Financial And Managerial Accounting

Accounting

ISBN:9781337902663

Author:WARREN, Carl S.

Publisher:Cengage Learning,

Cornerstones of Cost Management (Cornerstones Ser...

Accounting

ISBN:9781305970663

Author:Don R. Hansen, Maryanne M. Mowen

Publisher:Cengage Learning

Managerial Accounting: The Cornerstone of Busines...

Accounting

ISBN:9781337115773

Author:Maryanne M. Mowen, Don R. Hansen, Dan L. Heitger

Publisher:Cengage Learning

Essentials of Business Analytics (MindTap Course ...

Statistics

ISBN:9781305627734

Author:Jeffrey D. Camm, James J. Cochran, Michael J. Fry, Jeffrey W. Ohlmann, David R. Anderson

Publisher:Cengage Learning