Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN: 9781259696527

Author: J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Question

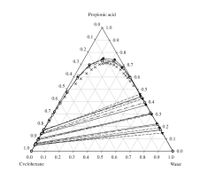

Below is a ternary liquid phase diagram containing propionic acid and water at 70:30 mass ratio is fed to a mixer at 3.181 kg/s with pure cyclohexane as solvent.

What is the flow rate of the pure cyclohexane (solvent) in order to attain 30:70 mass ratio of solute and solvent in the extract (solvent-rich) stream?

Transcribed Image Text:Propionic acid

0.0

1.0

0.1

0.9

0.2

0.8

0.3

0.7

0.4

+ ++

t,

0.6

0.5

0.5

0.6

0.4

0.7

0.3

0.8

0.2

0.9

0.1

1.0

0.0

0.1

0.2

0.3

0.4

0.5

0.0

0.6

0.7

0.8

0.9

1.0

Cyclohexane

Water

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 3 steps with 11 images

Knowledge Booster

Similar questions

- 5-24. Small amounts of an inorganic salt contained in an organic fluid stream can be removed by contacting the stream with pure water as illustrated in Figure 5.24. The process requires that the organic and aqueous streams be contacted in a mixer that provides a large surface area for mass transfer, and then separated in a settler. If the mixer is efficient, the two phases will be in equilibrium as they leave the settler and you are to assume that this is the case for this problem. You are given the following information: a) Organic stream flow rate: 1000 lbm/min b) Specific gravity of the organic fluid: 0.87 Porg PH20 11 c) Salt concentration in the organic stream entering the mixer: (cA)org 0.0005 mol/L org d) Equilibrium relation for the inorganic salt: (corg = Keg.A (CA)ag where Keg 1/60 Here (cAag represents the salt concentration in the aqueous phase that is in equilibrium with the salt In this problem you are asked to determine the mass flow rates concentration in the organic…arrow_forwardA long glass capillary with a diameter of 0.1 cm is in contact with water on one side and dry air on the other. Water vapor evaporates from the side in contact with water and diffuses through the capillary to the other side. Using the following given data, calculate the rate at which water evaporates in this system in [g/s].Isothermal diffusion (20℃)Vapor pressure of water 17.5 mmHg (20℃)Water diffusivity 0.3 cm2/s (20℃)Dry air pressure 760 mmHgDural length 10 cmGas constant R=82 cm3atm/mol K18 g/mol molecular weight of waterarrow_forwardA sheet of steel with 100cm2 area has nitrogen(N2) atmospheres on both sides and is permitted to achieve a steady-state diffusion condition. In order to increase the flow rate of N2, which of the following modifications is useful? Steel sheet O Increase the N2 pressure at C1 O Decrease the temperature. O Increase the N2 pressure at C2 O Increase the thickness of the steel sheet.arrow_forward

- A continuous distillation column is operating at steady state to purify alcohol from a mixture of water and alcohol. Addition of salt breaks the azeotrope and allows for more pure alcohol. Liquid containing, by mass, 55% isopropanol, 8% salt and the rest water, is fed to the column. The vapor product stream (distillate) at the top of the column flows at the same mass flow rate as the bottom liquid stream (bottoms). The vapor product stream contains 80% isopropanol and no salt.a. Define azeotrope and explain why adding salt allows removal of more water from alcohol.b. Draw and label a flowchart. Do degree of freedom analysis to see if all unknowns can be solved.c. Calculate the mass fraction of salt in the bottoms.d. Calculate the fraction of isopropanol from the feed that is in the bottoms (kg IPA in bottoms/kg IPA in feed).arrow_forward2.3 Kg/s of solid containing 0.55 Kg/s soluble material is to be washed with 2.8 Kg/s pure solvent in a counter – current unit . The final residue is to contain not more than 0.1% solute when dried . Find the number of stages given that the amount of solution in under flow varies with solute concentration according to the relation : W = 0.2 X + 0.3 , Also find the concentration and quantities in and out from each stage . subject is mass transfer, leaching processarrow_forwardAn input stream contains oil sands, comprising 14.0% oil, the remainder being solid sand particles. In the initial stages of steady-state processing, the oil sands are mixed with warm water and pumped to a settling tank. In this tank three layers are formed. The three layers are: 1. Bottom layer containing 95.0% sand and 5.00% water 2. Middle layer containing 5.00% oil and 95.0% water 3. Top layer containing 70.0% oil and 30.0% water The top layer is skimmed off and sent for further processing, while the bottom two layers are disposed of. How much warm water is added to 200 tonnes of oil sands in this process if 85.0% of the total oil is recovered in the top layer (3 sig. figs)? All percentages given are weight percentages.arrow_forward

- A cylindrical tube connects two large gas tanks (Tank-1 and 2). Both tanks contain mixture of carbon dioxide (CO₂) and sulphur dioxide (SO₂). The partial pressure of carbon dioxide in Tank-1 is 80 kPa and in Tank-2 is 20kPa. Both tanks and connecting tube are at 100 kPa and 263 K. The tube is 100 mm long. The diffusion coefficient of carbon dioxide is 0.064 cm²/s at 100 kPa and 263 K, and molar mass of carbon dioxide is 44 kg/kmol. Calculate the steady-state flux of carbon dioxide through the tube, assuming ideal gas is applied. 11.755 x 10-3 mol/m².s O 7.755 x 10-3 mol/m².s 4.755 x 10-3 mol/m².s 1.755 x 10-3 mol/m².sarrow_forwardConsider a solid sphere, of radius R, which is placed in a large body of unstirred, aqueous solution, as shown in Figure 1. The dissolution of the solid A, is slow enough that quasi-steady-state can be assumed. Given the solubility of A in the solution is CA* at the surface of the sphere and assume there is a bulk diffusion in the solution (i.e. the term yA(NA+Nu) is not zero). 1.) Derive an expression for the concentration distribution of A in the solution; and 2.) develop a mathematical relationship for molar flow rate of A, entering the solution at the surface of the sphere. FLUID SOLID 'A' &r Rsarrow_forwardA stream containing propionic acid and water at 60:40 mass ratio is fed to a mixer at 3 kg/s with pure cyclohexane as solvent. What should be the flow rate of the solvent in order to attain 40:60 mass ratio of solute and solvent in the extract (solvent-rich) stream? Prepare graphical and computational solution.arrow_forward

- A double effect evaporator is used to concentrate an 18% CuSO4 solution. At the end of evaporation, 26,000 kg/h of 50% CuSO4 solution were obtained. If the water evaporated in the second effect is half the water evaporated in the first effect, determine: a) The amount of solution fed into the first effect. b) The amount of water evaporated in the first and second effect. c) The amount of solution fed into the second effect, as well as its composition. Problem diagram 18% CuSO4 82% H₂O M₁ M₂ M3 X CuSO4 Y H₂O A 2 M4 = 0.5 M₂ M5 H₂O steam M6 M2 M6 is the water that condenses 26 000 kg/hr 50% CuSO4 50% H2₂Oarrow_forwardConsider a diffusion process in a semi-infinite solid with a source at x=0 mm, the concentration of the diffusing species is 2 nm-3 at x=5 mm and t=1 hr (since the start of the process). At what time the concentration at x=15 mm will reach 3 nm-3 ?arrow_forwardThe feed stream to a distillation column contains 30 % propane, 50 % butane and 20 % pentane. The overhead tops product concentrate contains 80 % propane and 15 % butane, and the bottoms product contains 2 % propane. Determine the following: a) The yield (%) of overhead product per unit of feed. b) The concentration of butane and pentane in the bottoms product stream. c) The recovery (%) of propane from the feed into the overhead product (i.e. what fraction of propane in the feed stream exits in the overhead product). d) The recovery (%) of pentane from the feed into the bottoms product.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Introduction to Chemical Engineering Thermodynami...

Chemical Engineering

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind...

Chemical Engineering

ISBN:9781118431221

Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:WILEY

Elements of Chemical Reaction Engineering (5th Ed...

Chemical Engineering

ISBN:9780133887518

Author:H. Scott Fogler

Publisher:Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:9781285061238

Author:Lokensgard, Erik

Publisher:Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:9780072848236

Author:Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:McGraw-Hill Companies, The