Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

Please help me solve these using solver in excel

Transcribed Image Text:AutoSave OFF

PC...

Assignment 8.2

Tell me

✓

✓

BD

Share

Comments

✓

✓

Sort &

Filter

Find &

Select

Analyze

Data

Sensitivity

T

U

V

W

X

Y

Home Insert

Draw

Page Layout Formulas

Data

Review View

Automate

Calibri (Body)

✓

11

✓

Aˆ A

Wrap Text

General

✓

Insert ✓ Σ

Delete ▾

Paste

B I U

✓

✓

✓

Merge & Center

$

✓

%

0-

.00

Conditional Format Cell

Formatting as Table Styles

Format

M17

fx

B

C

D

E

F

G

H

|

J

K

L

M

N

O

P

0

R

S

A

1

2

3

4

5

6

7

8

9

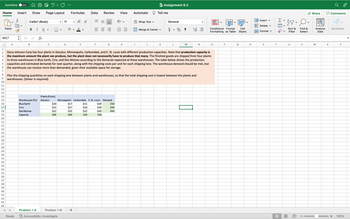

Dana Johnson Corp has four plants in Decatur, Minneapolis, Carbondale, and E. St. Louis with different production capacities. Note that production capacity is

the maximum amount the plant can produce, but the plant does not necessarily have to produce that many. The finished goods are shipped from four plants

to three warehouses in Blue Earth, Ciro, and Des Moines according to the demands expected at these warehouses. The table below shows the production

capacities and estimated demands for next quarter, along with the shipping costs per unit for each shipping lane. The warehouse demand should be met, but

the warehouse can receive more than demanded, given their available space for storage.

Plan the shipping quantities on each shipping lane between plants and warehouses, so that the total shipping cost is lowest between the plants and

warehouses. (Solver is required)

10

11

12

13

14

15

Warehouses (To)

Plants (From)

Decatur

Minneapolis Carbondale E. St. Louis Demand

16

Blue Earth

$20

$17

$21

$29

250

17

Ciro

$25

$27

$20

$30

200

18

Des Moines

$22

$25

$22

$30

350

19

Capacity

300

200

150

150

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

Ready

Problem 1-A

Problem 1-B

Accessibility: Investigate

+

A

+

100%

Transcribed Image Text:AutoSave OFF

PC...

Assignment 8.2

Tell me

Home Insert

Draw

Page Layout Formulas

Data Review View

Automate

Calibri (Body)

✓

11

✓

Aˆ A

Wrap Text

General

Paste

B

I U

✓

✓

✓

Merge & Center

$

✓

% 9

A1

fx

Insert ✓ Σ

✓

Delete ▾

.00

0-

Conditional Format

Formatting as Table

Cell

Styles

Format

A

B

C

D

E

F

G

H

J

K

L

M

N

1

2

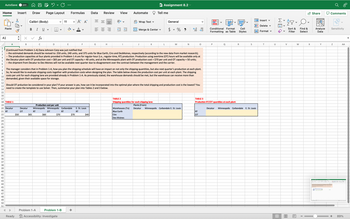

(Continued from Problem 1-A) Dana Johnson Corp was just notified that

3

4

5

-- the estimated demands should be revised to: 250 units, 240 units, and 375 units for Blue Earth, Ciro and DesMoines, respectively (according to the new data from market research);

-- The production capacities at four plants provided in Problem 1-A are for regular-hour (i.e., regular-time, RT) production. Production using overtime (OT) hours will be available only at

the Decatur plant with OT production cost = $65 per unit and OT capacity = 40 units, and at the Minneapolis plant with OT production cost = $70 per unit and OT capacity = 50 units;

-- the shipment from Decatur to Des Moines will not be available next quarter due to disagreement over the contract between the management and the carrier.

6

7

8

9

10

11

The manager considers that in Problem 1-A, how you plan the shipping schedule will have an impact on not only the shipping quantities, but also next quarter's production at each plant.

So, he would like to evaluate shipping costs together with production costs when designing the plan. The table below shows the production cost per unit at each plant. The shipping

costs per unit for each shipping lane are provided already in Problem 1-A. As previously stated, the warehouse demands should be met, but the warehouse can receive more than

demanded, given their available space for storage.

Should OT prduction be considered in your plan? If your answer is yes, how can it be incorporated into the optimal plan where the total shipping and production cost is the lowest? You

need to create the template to use Solver. Then, summarize your plan into Tables 2 and 3 below.

$50

18 TABLE 1

20 Decatur

21 RT

26

28

30

36

38

40

46

48

50

121992222222222222≈≈≈33333327734444455

16

Production cost per unit

✓

✓

BD

Share

Comments

✓

✓

Sort &

Filter

Find &

Select

Analyze

Data

Sensitivity

P

Q

R

S

T

U

V

W

X

Y

Z

AA

TABLE 2

TABLE 3

E. St. Louis

Warehouses (To)

Shipping quantities for each shipping lane

Plants (From)

Decatur

Production RT/OT quantities at each plant

Minneapolis Carbondale E. St. Louis

Decatur

Minneapolis Carbondale

E. St. Louis

RT

Blue Earth

$70

$40

Ciro

RT

OT

Des Moines

Minneapolis Minneapolis Carbondale

Decatur

от

RT

$65

Ready

от

$60

RT

$70

Problem 1-A

Problem 1-B

Accessibility: Investigate

+

A

+

89%

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps

Knowledge Booster

Similar questions

- What is the answer in this number 4?arrow_forwardFind the prime factorization of 2014.arrow_forwardMillie wants to install a new carpet in the living room of her house. She calculated the square footage of the room and then multiplied it by a set cost factor to estimate the cost. This is an example of_________ Group of answer choices Parametric estimating Three-point estimating Bottom-up estimating Analogous estimatingarrow_forward

- apply appropriate techniques to solve a range of models of mathematical and real-world problems analyse the effects of changing model parameters on LP model predictions * select and develop appropriate mathematical models for decision making problems (a) A stationary supplies company wishes to produce deluxe and budget ink pens. Deluxe ink pens require eight units of material and 9 minutes to produce each pen. Budget ink pens require six units of material and 4 minutes to produce each pen. The company has 38.25 hours of labour and 1950 units of material available per week. Profit for deluxe ink pens is $2.40 per pen and for budget ink pens is $1.75 per pen. The company also wants the number of deluxe ink pens to be produced to be at least 6 times the number of budget ink pens produced. Formulate a Linear Programming problem to determine the company's best production plan to maximise profit (do not solve). (b) Solve the following Linear Programming problem using the Simplex Method. Full…arrow_forwardPlease do not give solution in image format thankuarrow_forwardHi, would you be able to help me with this question? Thanksarrow_forward

- Prove the following using strong induction. Suppose you are gifted a collection of 3n pokéballs; all of the the pokéballs have the same size and weight except for one which is slightly heavier, and otherwiselook and feel exactly the same as the others. You are tasked with identifying theheavy pokéball and have at your disposal a set of balancing scales which can be usedto compare the weights of two collections of pokéballs. The scales can show whetherthe two collections have the same weight, or can show which collection is heavier if theweights are different. Prove using strong induction that you can identify the heavypokéball out of 3n pokéballs using n weighing operations.arrow_forwardHelp pleasee 15) Mining Company operates two mines for the purpose of extracting gold and silver. The Saddle Mine costs $26,000/day to operate, and it yields 50 oz of gold and 3000 oz of silver each of x day. The Horseshoe Mine costs $16,000/day to operate, and it yields 75 oz of gold and 1000 oz of silver each of y day. Company management has set a target of at least 650 oz of gold and 18,000 oz of silver. (a) How many days should each mine be operated so that the target can be met at a minimum cost?The minimum is C = at (x, y) = Suppose C = cx + 16,000y. Find the range of values that the Saddle Mine's daily operating cost, the coefficient c of x, can assume without changing the optimal solution.≤ CI Find the range of values that the requirement for gold can assume.≤ (requirement for gold) ≤ Find the shadow price for the requirement for gold. (Round your answer to the nearest cent.)arrow_forwardFind the prime factorization of 92169.arrow_forward

- Please note that formulating linear program doesn't need coding but only modelling. It's operational Research problem. Garden House produces three custom flower seed mixes. Garden House is trying to decide how many pounds of each mix to produce for the upcoming planting season. All three mixes require two seed types, the all-star and the purple power. Garden house can obtain at most 25 lbs of all-star and 30 lbs of purple power seeds. Seed requirements, along with the revenue per pound of each, are given in Table 1, All star seeds cost $2/lb, and purple power seeds cost $3/lb. From past history, the company knows that it will be able to sell at most 60 lbs of mix A, but that they will sell as much of mix B and mix C as they produce. Formulate a linear program to help garden house maximize its profits.arrow_forwardExample 5: Find lim Solution // lim X-X x 2 + 2 = lim X-X (x+2) x→∞ √√x²+1) X-X x + 0 0 11 1+arrow_forwardLong-Life Insurance has developed a linear model that it uses to determine the amount of term life insurance a family of four should have, based on the current age of the head of the household. The equation is:y = 850 − .1xwherey = Insurance needed ($000)x = Current age of head of household a. Plot the relationship on a graph. b. Use the equation to determine the amount of term life insurance to recommend for a family of four if the head of the household is 30 years old.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.