Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

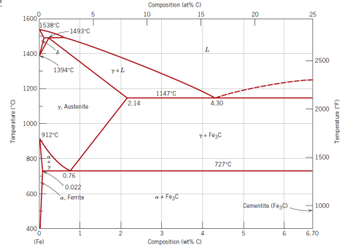

Answer the following questions using the phase diagram of iron and iron carbide below:

For a 99.70 wt% Fe–0.30 wt% C alloy at a temperature of 600oC, determine the

following:

a. The fractions of total ferrite and cementite phases

b. The fractions of the pro eutectoid ferrite and pearlite

Transcribed Image Text:Temperature (°C)

1600

1400

1200

1000

800

600

1538 C

4000

912°C

2

-1493°C

1394°C

7. Austenite

0.76

0.022

a, Ferrite

5

Y+L

2

2.14

Composition (at % C)

15

10

1147 C

a + Fe₂C

L

4.30

Y+F03C

4

Composition (wt% C)

727°C

20

Cementite (Fe-C)

5

6

25

2500

2000

1500

1000

6.70

Temperature (°F)

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 4 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Using the isothermal transformation diagram given in Figure 2 for a specific material composition to answer the following (this is NOT an Fe-C steel!). NOTE: Assume that you begin with a single-phase sample of α at 790 C.a. What temperature on the diagram corresponds to the α-to-γ phase transformation temperature that would be found on an equilibrium phase diagram? Explain your answer. b. What temperature would provide the most rapid, isothermal phase transformation of α to γ? What would be the minimum time from onset of the phase transformation to its completion? c. On Figure 2, draw and label a cooling schedule (from 790 C) that will produce a single-phase α material at 100 C. How does the thickness of the piece of material influence your ability to create a single-phase α structure? d. Why does the time to initiate phase transformation become smaller as the temperature is reduced within the temperature range above the “nose” of the TTT diagram? Be specific, what process is…arrow_forwardA sample of bronze is composed of 12 wt% tin, 3 wt% aluminum, and 85 wt% copper. Determine at% of tin in the alloy.arrow_forwardMaterial science Assuming this system forms a laminar type eutectic, determine the volume proportion of phases for an equilibrium solidified 50% Pb alloy. Sketch the expected microstructure.arrow_forward

- Consider 2.0 kg of austenite containing 0.5 wt% C and cooled to just below 727°C (1341°F). (a) What is the proeutectoid phase? (b) How many kilograms each of pearlite, the proeutectoid phase, and cementite form?arrow_forwardFrom the phase diagram of the Fe-0.25wt%C alloy below, determine the phase fraction and elemental composition of the resulting phase immediately after solidification across the eutectoid line (725 C). a.alpha_eutectoid = 96.6 wt% and cementite = 29.85 wt% b.alpha_eutectoid = 96.6 wt% and cementite = 3.4 wt% c.alpha_eutectoid = 1.05 wt% and cementite = 29.85 wt% d.alpha_eutectoid = 29.85 wt% and cementite = 1.05 wt%arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY