Introductory Circuit Analysis (13th Edition)

13th Edition

ISBN: 9780133923605

Author: Robert L. Boylestad

Publisher: PEARSON

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

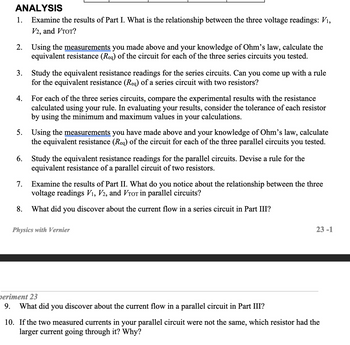

Transcribed Image Text:ANALYSIS

1. Examine the results of Part I. What is the relationship between the three voltage readings: V₁,

V2, and VTOT?

2. Using the measurements you made above and your knowledge of Ohm's law, calculate the

equivalent resistance (Req) of the circuit for each of the three series circuits you tested.

3. Study the equivalent resistance readings for the series circuits. Can you come up with a rule

for the equivalent resistance (Req) of a series circuit with two resistors?

4. For each of the three series circuits, compare the experimental results with the resistance

calculated using your rule. In evaluating your results, consider the tolerance of each resistor

by using the minimum and maximum values in your calculations.

5. Using the measurements you have made above and your knowledge of Ohm's law, calculate

the equivalent resistance (Req) of the circuit for each of the three parallel circuits you tested.

6. Study the equivalent resistance readings for the parallel circuits. Devise a rule for the

equivalent resistance of a parallel circuit of two resistors.

7. Examine the results of Part II. What do you notice about the relationship between the three

voltage readings V₁, V2, and VTor in parallel circuits?

8. What did you discover about the current flow in a series circuit in Part III?

Physics with Vernier

periment 23

9. What did you discover about the current flow in a parallel circuit in Part III?

23-1

10. If the two measured currents in your parallel circuit were not the same, which resistor had the

larger current going through it? Why?

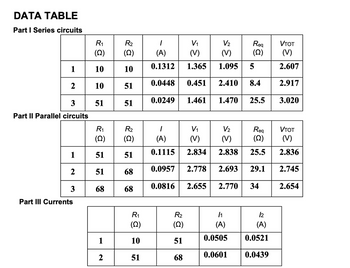

Transcribed Image Text:DATA TABLE

Part I Series circuits

1

2

3

Part II Parallel circuits

R₁

(Q)

151

2

3

R₁

(2)

10

10

51

Part III Currents

R₂

(Q)

10

51

51

R₂

(2)

51

51 68

68

68

1

2

R₁

(22)

10

51

1

V₁

V₂

(A)

(V) (V)

0.1312

1.365

0.0448

0.451

0.0249 1.461

1

(A)

0.1115

0.0957

0.0816 2.655

R₂

(Q)

51

68

1.095

2.410

1.470

Req

(22)

/1

(A)

0.0505

0.0601

5

8.4

V₁

V₂

Req

(V) (V)

(Q)

2.834

2.838

25.5

2.778 2.693 29.1

2.770

34

25.5

12

(A)

0.0521

0.0439

VTOT

(V)

2.607

2.917

3.020

VTOT

(V)

2.836

2.745

2.654

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 4 steps with 1 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, electrical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Q1- Determine the range of adjustable resistance, R. for a Wheatstone bridge circuit as shown in Figure Q1 that can measure voltage at range between 0 to 10 V. The voltage source is 50 V and fixed resistances, R1 = R2 = R3 = 1 K ohm, next, determine the range of current can be measured by using galvanometer with internal resistance is 200ohmarrow_forwardthe voltage that would be developed across a 50 ohm load connected to the terminals of a battery with 20 V no load terminal voltage and 5 ohm internal resistance is?arrow_forward

Recommended textbooks for you

Introductory Circuit Analysis (13th Edition)Electrical EngineeringISBN:9780133923605Author:Robert L. BoylestadPublisher:PEARSON

Introductory Circuit Analysis (13th Edition)Electrical EngineeringISBN:9780133923605Author:Robert L. BoylestadPublisher:PEARSON Delmar's Standard Textbook Of ElectricityElectrical EngineeringISBN:9781337900348Author:Stephen L. HermanPublisher:Cengage Learning

Delmar's Standard Textbook Of ElectricityElectrical EngineeringISBN:9781337900348Author:Stephen L. HermanPublisher:Cengage Learning Programmable Logic ControllersElectrical EngineeringISBN:9780073373843Author:Frank D. PetruzellaPublisher:McGraw-Hill Education

Programmable Logic ControllersElectrical EngineeringISBN:9780073373843Author:Frank D. PetruzellaPublisher:McGraw-Hill Education Fundamentals of Electric CircuitsElectrical EngineeringISBN:9780078028229Author:Charles K Alexander, Matthew SadikuPublisher:McGraw-Hill Education

Fundamentals of Electric CircuitsElectrical EngineeringISBN:9780078028229Author:Charles K Alexander, Matthew SadikuPublisher:McGraw-Hill Education Electric Circuits. (11th Edition)Electrical EngineeringISBN:9780134746968Author:James W. Nilsson, Susan RiedelPublisher:PEARSON

Electric Circuits. (11th Edition)Electrical EngineeringISBN:9780134746968Author:James W. Nilsson, Susan RiedelPublisher:PEARSON Engineering ElectromagneticsElectrical EngineeringISBN:9780078028151Author:Hayt, William H. (william Hart), Jr, BUCK, John A.Publisher:Mcgraw-hill Education,

Engineering ElectromagneticsElectrical EngineeringISBN:9780078028151Author:Hayt, William H. (william Hart), Jr, BUCK, John A.Publisher:Mcgraw-hill Education,

Introductory Circuit Analysis (13th Edition)

Electrical Engineering

ISBN:9780133923605

Author:Robert L. Boylestad

Publisher:PEARSON

Delmar's Standard Textbook Of Electricity

Electrical Engineering

ISBN:9781337900348

Author:Stephen L. Herman

Publisher:Cengage Learning

Programmable Logic Controllers

Electrical Engineering

ISBN:9780073373843

Author:Frank D. Petruzella

Publisher:McGraw-Hill Education

Fundamentals of Electric Circuits

Electrical Engineering

ISBN:9780078028229

Author:Charles K Alexander, Matthew Sadiku

Publisher:McGraw-Hill Education

Electric Circuits. (11th Edition)

Electrical Engineering

ISBN:9780134746968

Author:James W. Nilsson, Susan Riedel

Publisher:PEARSON

Engineering Electromagnetics

Electrical Engineering

ISBN:9780078028151

Author:Hayt, William H. (william Hart), Jr, BUCK, John A.

Publisher:Mcgraw-hill Education,