Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

ROUND UP TO 4 DECIMAL PLACES. Draw and label the P-V and T-S diagrams.

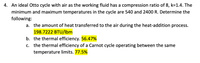

Transcribed Image Text:4. An ideal Otto cycle with air as the working fluid has a compression ratio of 8, k=1.4. The

minimum and maximum temperatures in the cycle are 540 and 2400 R. Determine the

following:

a. the amount of heat transferred to the air during the heat-addition process.

198.7222 BTU/lbm

b. the thermal efficiency. 56.47%

c. the thermal efficiency of a Carnot cycle operating between the same

temperature limits. 77.5%

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 4 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- An ideal regenerative cycle is executed with steam generation at 10 MPa and 600 deg C. Before condensation at 0.005 MPa, steam is extracted for feedwater heating first at 2.5 MPa and second at 0.6 MPa. On the basis of 1 kg of throttle steam, find: a. m1 and m2 in kg/kg b. ec in percent c. ee in percent Reminder: 1. For values taken from the steam tables: Use them as is, do not round off. 2. For values obtained by interpolation and final answers obtained by solving, use FOUR (4) decimal places.arrow_forward4. An ideal Otto cycle with air as the working fluid has a compression ratio of 8, k=1.4. The minimum and maximum temperatures in the cycle are 540 and 2400 R. Determine the following:a. the amount of heat transferred to the air during the heat-addition process.198.7222 BTU/lbmb. the thermal efficiency. 56.47%c. the thermal efficiency of a Carnot cycle operating between the sametemperature limits. 77.5%arrow_forwardAn ideal regenerative cycle is executed with steam generation at 10 MPa and 600 deg C. Before condensation at 0.005 MPa, steam is extracted for feedwater heating first at 2.5 MPa and second at 0.6 MPa. On the basis of 1 kg of throttle steam, find:a. m1 and m2 in kg/kgb. ec in percentc. ee in percent Reminder:1. For values taken from the steam tables: Use them as is, do not round off.2. For values obtained by interpolation and final answers obtained by solving, use FOUR (4) decimal places.PLEASE USE THIS STEAM TABLE:https://docs.google.com/document/d/1wUPYkDmHnCMBEuLRMRTGEfz4D5kkohT4/editarrow_forward

- In an ideal Otto Cycle, the temperature at the end of the heat addition process is2600 deg. F. and the temperature at the end of the expansion process is 883deg. F. What is the compression Ratio?arrow_forwardA gas turbine uses the Joule cycle. The inlet pressure and temperature to thecompressor are respectively 1 bar and -10oC. After constant pressure heating, thepressure and temperature are 7 bar and 700oC respectively. The flow rate of air is 0.4kg/s. Calculate the following.1. The cycle efficiency.2. The heat transfer into the heater.3. the nett power output. = 1.4 cp = 1.005 kJ/kg Karrow_forward2.6). A gas-turbine plant operates on the regenerative Brayton cycle with two stages of reheating and two stages of intercooling between the pressure limits of 100 and 1200 kPa. The working fluid is air. The air enters the first and the Regenerator second stages of the compressor at 300 K and 350 K, respectively, and the first and Reheater the second stages of the turbine at Comb. cham. 1400 K and 1300 K, respectively. 6 Wnet Assuming both the compressor and the Comp. I Comp. II Turb. I Turb. II turbine have an isentropic efficiency of 80% and the regenerator has an effectiveness of 75%, determine (a) the Fig. p2.6. Intercooler back-work ratio and the network output, For two-stage compression and expansion, the work input is minimized and the work output is maximized when both stages of the compressor and the turbine have the same pressure ratio. and (b) the thermal efficiency. 2.7). A simple gas turbine, has the following data: Compressor pressure ratio, p = 20 Turbine inlet…arrow_forward

- In a Carnot heat engine cycle, piston-type, operating between 307 and17°C_the maximum and minimum pressures are 62.4 bar and 1.04 bar respectively. Calculate the cycle efficiency and the work ratio (a). Assume air to be the working fluid. Draw the cycle on P-v diagram by assuming the start of isothermal expansion being the state point 1.arrow_forwardthe back work ratio and the thermal efficiency of the cycle assuming a regenerator with 75 and constant specific heats is used with C0.718 kJ/kg.K and C1.005 kJ/kg.K. Determine expansion. The pressure ratio across cach stage of the compressor and turbine is 3. The air Q2: Consider an ideal gas-turbine cycle with two stages of compression and two stages of kinetic and potential energy changes are negligible. The air standard assumptions are applicable enters cach stage of the compressor at 300 K and each stage of the turbine at 1200 K. The percent effectiveness is used.arrow_forwardRankine Cycle (Thermodynamics) Show the illustration diagram and complete and step by step solution.arrow_forward

- An ideal Bryton cycle with regeneration using air as the working fluid has a pressure ration of 10. The minimum and maximum temperatures in the cycle are 300 and 1200 K. Assuming an effectiveness of 100%, find the thermal efficiency of the cycle and the net specific work generation in KJ/kg (work per unit mass of air passing through the engine). Assume constant specific heats.arrow_forward6. An ideal Rankine cycle operates between a boiler pressure of 4 Mpa and a condenser pressure of 10 kpa. The exit steam from the turbine should have a quality of 96% and the power output of the turbine should be 80MW. Determine 8. The minimum boiler exit temperature The efficiency of the cycle The mass flow rate of steam a. b. C.arrow_forwardOption D. 2.53arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY