Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

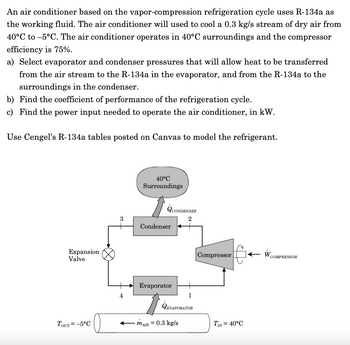

Transcribed Image Text:An air conditioner based on the vapor-compression refrigeration cycle uses R-134a as

the working fluid. The air conditioner will used to cool a 0.3 kg/s stream of dry air from

40°C to -5°C. The air conditioner operates in 40°C surroundings and the compressor

efficiency is 75%.

a) Select evaporator and condenser pressures that will allow heat to be transferred

from the air stream to the R-134a in the evaporator, and from the R-134a to the

surroundings in the condenser.

b) Find the coefficient of performance of the refrigeration cycle.

c) Find the power input needed to operate the air conditioner, in kW.

Use Cengel's R-134a tables posted on Canvas to model the refrigerant.

Expansion

Valve

TOUT = -5°C

3

40°C

Surroundings

QCONDENSER

2

Condenser

Evaporator

1

QEVAPORATOR

-MAIR = 0.3 kg/s

Compressor

TIN = 40°C

COMPRESSOR

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 3 steps with 1 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- ! Required information NOTE: This is a multi-part question. Once an answer is submitted, you will be unable to return to this part. Refrigerant-134a enters the condenser of a residential heat pump at 800 kPa and 50°C at a rate of 0.024 kg/s and leaves at 750 kPa subcooled by 3°C. The refrigerant enters the compressor at 200 kPa superheated by 4°C. (Take the required values from saturated refrigerant-134a tables.) Он 750 kPa (3) Condenser Expansion valve Evaporator +M QL 800 kPa 50°C Compressor Determine the COP of the heat pump. (You must provide an answer before moving to the next part.) The COP of the heat pump isarrow_forwardThe figure below shows a two-stage vapor-compression refrigeration system with ammonia as the working fluid. The system uses a direct-contact heat exchanger to achieve intercooling. The evaporator has a refrigerating capacity of 40 tons and produces -30°F saturated vapor at its exit. In the first compressor stage, the refrigerant is compressed adiabatically to 140 lbf/in.², which is the pressure in the direct contact heat exchanger. Saturated vapor at 140 lbf/in.² enters the second compressor stage and is compressed adiabatically to 250 lbf/in.² Each compressor stage has an isentropic efficiency of 85%. There are no significant pressure drops as the refrigerant passes through the heat exchangers. Saturated liquid enters each expansion valve. Determine: Expansion valve 6- Condenser Direct contact heat exchanger Expansion valve (a) the ratio of mass flow rates, m3/my. (b) the power input to each compressor stage, in horsepower. (c) the coefficient of performance Comp Comp Evaporatorarrow_forwardData for steady-state operation of a vapor-compression refrigeration cycle with Refrigerant 134a as theworking fluid are given in the table below. State 1 is at the compressor inlet. The cooling capacity (i.e therate at which heat is removed from the cooled space) is 4.6 tons. 1 ton of refrigeration is equivalent to211 kJ/min. Ignoring heat transfer between the compressor and its surroundings, sketch the ?-? diagramof the cycle and determinea) the mass flow rate of the refrigerant, in kg/min.b) the isentropic compressor efficiency.c) the coefficient of performance.State ? (bar) ? (°C) ℎ (kJ/kg) ? (kJ/kg-K)arrow_forward

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY