Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Question

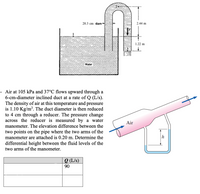

Transcribed Image Text:20.3 cm diam

2.44 m

1.22 m

Water

Air at 105 kPa and 37°C flows upward through a

6-cm-diameter inclined duct at a rate of Q (L/s).

The density of air at this temperature and pressure

is 1.10 Kg/m³. The duct diameter is then reduced

to 4 cm through a reducer. The pressure change

across the reducer is measured by a water

Air

manometer. The elevation difference between the

two points on the pipe where the two arms of the

manometer are attached is 0.20 m. Determine the

differential height between the fluid levels of the

two arms of the manometer.

Q (L/s)

90

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- An iron bar 2.0 cm x 3.0 cm x 10.0 cm at a temperature of 95 °C is dropped into a barrel of water at 25 °C. The barrel is large enough so that the water temperature rises negligibly as the bar cools. The rate at which heat is transferred from the bar to the water is given by the expression Q (J/min) = UA (Th - Tw.) where U = 0.05 J/(min cm °C)] is a (cm) is the exposed surface area of the bar, T₁, and T are the surface temperature of the bar and the water temperature, respectively. The heat capacity of the bar is 0.46 J/(g °C). Heat conduction in iron is rapid enough for the temperature T, to be considered uniform throughout the bar. a) Write an energy balance on the bar M = (60 cm³)(7.7 g/cm³) = 462 g C₁ = 0.46 kJ/(kg-°C), T = 25°C U= 0.050 J/(min-cm² °C) |4=2[(2)(3) + (2)(10) +(3)(10)]cm² = 112 cm²arrow_forwardThe compressed air requirements of a textile factory are met by a large compressor that draws in 0.6 m3/s air at atmospheric conditions of 20°C and 1 bar (100 kPa) and consumes 300 kW electric power when operating. Air is compressed to a gage pressure of 8 bar (absolute pressure of 900 kPa), and compressed air is transported to the production area through a 15-cm-internal-diameter, 83-m-long, plastic (smooth) pipes with a surface roughness of 0.15 mm. The average temperature of compressed air in the pipe is 60°C. The compressed air line has 8 elbows with a loss coefficient of 0.6 each. In order to reduce the head losses in the piping and thus the power wasted, someone suggests doubling the diameter of the 83-m-long compressed air pipes. Calculating the reduction in wasted power, and determine if this is a worthwhile idea. Considering the cost of replacement, does this proposal make sense to you?arrow_forwardArgon is accelerated in a nozzle from 32 m/s at 666 K to 441 m/s and 196 kPa. If the heat loss is equal to 5.1 kJ/kg, determine the gas temperature at outlet in K to 1 decimal place. Take the gas constant as 0.2 (kPa m3)/(kg K) and assume constant specific heats cp=0.5 kJ/(kg K) and cv=0.3 kJ/(kg K).arrow_forward

- R-134a enters a compressor as a saturated vapor at 80 kPa and exits at a pressure of 400 kPa. If 44 kJ/kg of work is required and 5 kJ/kg of heat is lost to the surroundings. What is the outlet temperature. Round your answer to the nearest whole number.arrow_forwardA water is flowing through the duct having daimeter 15 cm and length 15 m. The inlet temperature of water is 100 °C & exit temperature is 5 °C respectively. Calculate the mass flow rate of water through the duct in mol/sec by considering heat transfer due to convection. Individual heat transfer coefficent is 15 w/m2K.arrow_forwardAn iron bar 2.0 cm x 3.0 cm x 10.0 cm at a temperature of 95 °C is dropped into a barrel of water at 25 °C. The barrel is large enough so that the water temperature rises negligibly as the bar cools. The rate at which heat is transferred from the bar to the water is given by the expression Q (J/min) = UA (T₁-T) where U = 0.05 J/(min cm °C)] is a (cm) is the exposed surface area of the bar, T, and T are the surface temperature of the bar and the water temperature, respectively. The heat capacity of the bar is 0.46 J/g °C). Heat conduction in iron is rapid enough for the temperature T, to be considered uniform throughout the bar. a) Write an energy balance on the bar b) Plot the expected plot of T, versus t and then curve fitting. M = (60 cm³) (7.7 g/cm³) = 462 g C, = 0.46 kJ/(kg-°C), T = 25°C U= 0.050 J/(min-cm².°C) 4 = 2[(2)(3)+(2)(10)+(3)(10)]cm² = 112 cm²arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY