Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

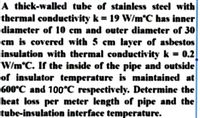

Transcribed Image Text:A thick-walled tube of stainless steel with

thermal conductivity k = 19 W/m°C has inner

diameter of 10 em and outer diameter of 30

cm is covered with 5 cm layer of asbestos

insulation with thermal conductivity k = 0.2

W/m°C. If the inside of the pipe and outside

of insulator temperature is maintained at

600°C and 100°C respectively. Determine the

heat loss per meter length of pipe and the

tube-insulation interface temperature.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- 1. A pipe is covered with three insulation layers where the corresponding thicknesses are 150 mm, 250mm and 300mm and the respective thermal conductivities are 3.2 W/m°C, 2.1 W/m°C and 1.5 W/m C. The length of the pipe is 3m. The inner side of the pipe which has a diameter of 300 mm is exposed to a hot gas at 1000 °C with convection coefficient of 50 W/m2°C and the temperature of the inner side of the pipe surface is 800 °C. The air outside the pipe is at 25°C with a convection coefficient of 35 W/m2°C. a. Draw a schematic diagram which shows the heat transfer process b. Calculate the Heat transfer rate c. The overall heat transfer coefficient "U" of the system based on the inner pipe d. Temperature at each of the layers and at the outermost surface of the pipe.arrow_forwardA dormitory at a large university, built 50 years ago, has exterior walls constructed of L, = 25-mm-thick sheathing with a thermal conductivity of ks = 0.1 W/m-K. To reduce heat losses in the winter, the university decides to encapsulate the entire dormitory by applying an L = 25-mm-thick layer of extruded insulation characterized by k; = 0.029 W/mK to the exterior of the original sheathing. The extruded insulation is, in turn, covered with an Lg = 5-mm-thick architectural glass with kg = 1.4 W/m-K. Determine the heat flux through the original and retrofitted walls when the interior and exterior air temperatures are Too₁ = 22°C and T∞,0 = -20°C, respectively. The inner and outer convection heat transfer coefficients are h; = 5 W/m²-K and h, = 25 W/m²-K, respectively. The heat flux through the original walls is i The heat flux through the retrofitted walls is i W/m². W/m².arrow_forwardApproximately 106 discrete electrical components are placed on a single integrated circuit (chip) with electrical heat dissipation of q = 30,000 W/m². The chip, which is very thin, is exposed to a dielectric liquid at its outer surface, with ho = 450 W/m²/K and To= 20°C, and is joined to a circuit board at its inner surface. The thermal contact resistance between the chip and the board is R = 104 m² K/W, and the board thickness and thermal conductivity are L = 4 mm and 00,0 kb = 0.95 W/m/K, respectively. The other surface of the board is exposed to ambient air for which hi = 30 W/m²/K and T = 20°C. a) Provide a resistance diagram labeling appropriate variables associated with this problem. b) Determine a symbolic expression for the temperature of the chip T. c) Calculate the chip temperature for the given parameters. Coolant ho 00,01 Air Too,i hi 三 三 -Chip q Te -Thermal contact resistance, Re -Board, kparrow_forward

- 150 circular copper fins (k = 400 W / m ° C) of 5 cm diameter and 1 mm thickness are attached to a pipe of 3 cm diameter and 150 cm length, the outer surface of which is kept at 220 ° C. The gap between the wings is 9 mm and the pipe is in an environment at 22 ° C. Since the heat transfer coefficient between the pipe and the ambient air is 80 W / m2 ° C, calculate the heat transfer amount from the finned pipe. Find the amount of increase in heat transfer.arrow_forwardA thick-walled tube of stainless steel (L = 0.50 m; k = 21.63 W/m-K) with an inside diameter of 0.0254 m and outside diameter of 0.0508 m, is covered with an insulation (∆x =0.0254 m) with k = 0.2423 W/m-K. If the inside wall temperature of the pipe is at 400 oC, calculate the temperature at the interface between the metal and the insulation (in oC) if the outside surface of the insulation is at 29.8 oC. 99 K in Pa.arrow_forwardA cast iron pipe (k = 80 W/m - oC) whose inner and outer diameters are 5 cm and 5.5 cm respectively is coverd with a 3 cm thick glass wool insulation (k = 0.05 W/m - oC) The temperature at the inner surface of the pipe is 320 oC and the interface temperature between the pipe and insulation is 300 oC. Determine the surface temperature of the insulation.arrow_forward

- Calculate the heat loss through a 100-ft² wall with an inside temperature of 65°F and an outside temperature of 35°F. Assume the exterior wall is composed of 2- in. of material having a 'k' factor of 0.80, and 2-in. of insulation having a conductance of 0.16. RTotal = 8.75 & Q = 342-Btu/hr RTotal = 9.2 & Q = 399-Btu/hr RTotal = 8.75 & Q = 399-Btu/hr RTotal = 9.2 & Q = 342-Btu/hr Hide hint for Question 3 Utilize the (RTotal = 1/C + x1/k1) equation.arrow_forwardWater flows through a cast steel pipe with k = 53 W/m-K with an outer diameter of 110 mm and 3.5 mm wall thickness. Calculate the thickness of insulation to be lagged on the pipe if the heat transfer per unit length is 6.5 W/m. The thermal conductivity of the insulation is 0.045 W/m-K. The water temperature is 15°C with convective heat transfer coefficient of 30 W/m2 -K while the outside air is -8°C and 18 W/m2 -K.arrow_forwardConsider a power transistor encapsulated in an aluminum case that is attached at its base to a square aluminum plate of thermal conductivity k= 240W/m.K, thickness L= 6mm, and width W= 20mm. The case is joined to the plate by screws that maintain a contact pressure of 1 bar, and the back surface of the plate transfers heat by natural convection and radiation to ambient air and large surroundings at T∞ =Tsur -25°C. The surface has an emissivity of ε=0.9, and the convection coefficient is h=4 W/m².K. The case is completely enclosed such that heat transfer may be assumed to occur exclusively through the base plate. a) If the air-filled aluminum-to-aluminum interface is characterized by an area of A₁=2×10-4 m² and contact resistance of R+c= 1.375 K/W, what is the maximum allowable power dissipation if the surface temperature of the case, Ts,c, is not to exceed 85°C? S,C' Transistor case Ts. Pelec S,C' Enclosure W Isur Base plate, (k,ε) Interface, Ac Air Th 801 b) How much should the h be…arrow_forward

- An industrial cold room has four 200 mm thick walls made of concrete. The walls are insulated on the outside with a layer of foam 60 mm thick. Cladding with a thickness of 15 mm protects the foam on the outside from the elements. The composite wall surface temperatures are –3 °C on the inside and 18 °C on the outside of the room respectively. The thermal conductivities of concrete, foam and cladding are 0.75, 0.35 and 0.5 W/m K respectively. Assuming perfect thermal contact between the layers of the composite walls, draw the typical temperature distribution across the layers and determine the heat energy gained per hour through all 4 walls of the room with a total surface area of 20 m2. What does this heat energy represent in terms of the refrigeration system of the cold room?arrow_forwardqo =4x107 W/m3 heat is produced in a spherical shaped radioactive material with a diameter of R = 0.2 m. The heat produced is released from the spherical surface to the environment in a stable regime. Thus, the temperature on the surface is kept constant at T=80°C The heat transmission coefficient of the object is given as k = 15W / m ° C. The temperature of the spherical body changes only in the radial direction. (T = T (r)). The distribution of temperature in a spherical body: =0 It is defined in the form. T, a) Obtain the temperature distribution T (r). b) Determine the boundary conditions. Find the maximum temperature. (Tmax)arrow_forwardI JUST NEED HELP WITH THE RED MARKED AREAS, THANKS!arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY