Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

A process at Printwright, Inc.’s largest facility is used to make plastic gears for a computer printer. The data found in the worksheet Prob. 9-15 were gathered by a quality analyst. The gears were designed to be 3.57 ` 0.05 centimeters (cm) in diameter. Construct a histogram of the data. What can you observe about the shape of the dis- tribution? What would you recommend to the production manager based on your analysis?

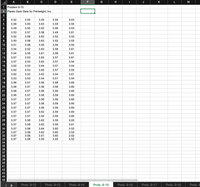

Transcribed Image Text:**Problem 9-15: Plastic Gear Data for Printwright, Inc.**

This dataset provides a set of measurements related to plastic gears produced by Printwright, Inc. The table comprises several columns with numerical values representing various data points for analysis.

---

### Data Table:

- **Row 1**: Header

- "Problem 9-15"

- **Row 2**: Subtitle

- "Plastic Gear Data for Printwright, Inc."

- **Rows 3 to 33**: Measurement Data

- Each row contains five numerical values.

- Example entries:

- Row 3: 3.52, 3.55, 3.55, 3.55, 3.63

- Row 4: 3.58, 3.55, 3.63, 3.55, 3.55

- ...

- Row 33: 3.57, 3.58, 3.55, 3.55, 3.52

---

### Overview:

The dataset appears structured for statistical analysis or quality control inspection, potentially analyzing measurements such as dimensions or tolerances of the gears. Each row represents a set of recorded measurements, which could pertain to specific batches or production runs. The uniformity and variation of these measurements may be evaluated to ensure the gears meet Printwright Inc.'s specifications and quality standards.

### Analysis Opportunities:

- **Quality Control**: Assess the consistency within each row and compare across multiple rows to identify trends and deviations.

- **Statistical Analysis**: Calculate mean, median, variance, and standard deviation for each set of measurements.

- **Graphical Representation**: Create histograms or charts to visualize data distribution for insights into manufacturing precision.

This data set provides a basis for deeper exploration into manufacturing quality and precision for Printwright, Inc.'s plastic gear production.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps with 1 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, operations-management and related others by exploring similar questions and additional content below.Similar questions

- The accounts receivable department at Rick WingManufacturing has been having difficulty getting customers topay the full amount of their bills. Many customers complainthat the bills are not correct and do not reflect the materials thatarrived at their receiving docks. The department has decided toimplement SPC in its billing process. To set up control charts, 10samples of 50 bills each were taken over a month’s time and theitems on the bills checked against the bill of lading sent by thecompany’s shipping department to determine the number of billsthat were not correct. The results were: SAMPLENO. NO. OFINCORRECTBILLS SAMPLENO. NO. OFINCORRECTBILLS1 6 6 52 5 7 33 11 8 44 4 9 75 0 10 2a) Determine the value of p -bar, the mean fraction defective.Then determine the control limits for the p -chart using a99.73% confidence level (3 standard deviations). Has thisprocess been in control? If not, which samples were out ofcontrol?b) How might you use the quality tools discussed in Chapter 6to…arrow_forwardA shirt manufacturer buys cloth by the 100-yard roll from a supplier. For setting up a control chart to manage the irregularities (e.g., loose threads and tears), the following data were collected from a sample provided by the supplier. SAMPLE 1 2 3 4 5 6 7 8 9 10 IRREGULARITIES 3 5 2 6 5 4 6 3 4 5 Determine the c¯�¯ , Sc�� , UCL and LCL for a c-chart with z = 2. Note: Round your answers to 2 decimal places. Suppose the next five rolls from the supplier had three, two, five, three, and seven irregularities. Is the supplier process under control? multiple choice Yes Noarrow_forwardA shirt manufacturer buys cloth by the roll from a supplier. For setting up a control chart to manage the irregularities (e.g., loose threads and tears), the following data were collected from a sample provided by the supplier. Sample Irregularities 1 2 2 1 3 4 4 2 5 0 6 4 7 3 8 0 9 2 10 1 Total 19 Calculate the LCL and UCL for a c-chart with z=2 LCL= 0, UCL = 4.66 LCL= 0, UCL = 3.28 LCL= -0.86, UCL = 3.28 LCL= -0.86, UCL = 3.51 LCL= -0.86, UCL = 4.66arrow_forward

- Hermitage DNA Labs, LLC collected temperature readings in an analysis process. The data can be found in the Problems Data Compute the mean and range of each sample and calculate control limits for x-bar and R charts using the appropriate From the charts constructed, does the process appear to be in statistical control?arrow_forwardChocolate, Inc. manufactures 4 ounce chocolate bars. Random samples of size four were taken and weighed. Eight hours of observation provided the following data. Sample Mean Range 1 3.96 0.13 2 4.03 0.16 3 3.97 0.16 4 4.14 0.16 5 3.88 0.11 6 4.03 0.18 7 4.04 0.18 8 4.07 0.14 (a) Determine the upper and lower control limits for the x chart. (Round your answers to four decimal places.) UCL=?? LCL=?? (b) Determine the upper and lower control limits for the R chart. (Round your answers to four decimal places.) UCL=?? LCL=??arrow_forwardCan you please explain the steps to create the control chart ?arrow_forward

- 2- Quality Control Charts A local brewery and bottling plant wants to keep track of the bottling filling equipment's accuracy, Bottles are to be filled with exactly 16 ounces of the drink. The following is data from the bottling equipment where 5 samples of bottles filled were pulled every hour and measured for actual quantity filled. 1- Calculate the UCL, LCL and mean for the X-bar and R data 2- Draw an X-Bar chart and a R chart. 3- Is this filling process in control or out of control? Hour X-bar R 1 16.05 .20 2 16.03 3 15.96 4 15.97 16.03 16.06 15.98 16.09 15.94 16.01 5 6 7 8 9 10 @n-5: A2 = 0.58, D3 =0, D4 = 2.11 .25 .62 .58 .71 .37 .46 .21 .35 .29arrow_forwardHermitage DNA Labs, LLC collected temperature readings in an analysis process. The data can be found in the Problems Data Compute the mean and range of each sample and calculate control limits for x-bar and R charts using the appropriate From the charts constructed, does the process appear to be in statistical control?arrow_forwardmq3arrow_forward

- Calculate the process capability (show your method). Is it acceptable? Comment on this result.arrow_forwardPlease do not give solution in image formate thanku. Jim Corner, owner of Corner Bike Rentals, wants to start analyzing his company's quality. For each bike rental, there are four types of customer complaints:(1) bike not working properly, (2) wrong bike size, (3) bike uncomfortable, and (4) bike broken during operation. During the past week, his company rented 280 bikes. He received a total of twenty-six complaints If Jim wanted to operate at the five-sigma level, what would his errors have needed to be over the past week?arrow_forwardPlease do part barrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.