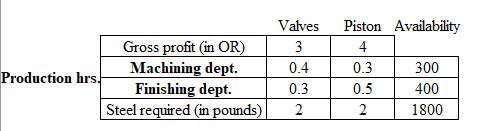

A manufacturer of engine parts produces valves and pistons at its main plant. Both parts are processed by the Machining Department and by the Finishing Department. Each valve requires 0.4 hours of machining time and 0.3 hours of finishing time, and each piston requires 0.3 hours of machining and 0.5 hours of finishing. The production process also requires 2 pounds of steel for each part.

A manufacturer of engine parts produces valves and pistons at its main plant. Both parts are processed by the Machining Department and by the Finishing Department. Each valve requires 0.4 hours of machining time and 0.3 hours of finishing time, and each piston requires 0.3 hours of machining and 0.5 hours of finishing. The production process also requires 2 pounds of steel for each part.

Practical Management Science

6th Edition

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:WINSTON, Wayne L.

Chapter2: Introduction To Spreadsheet Modeling

Section: Chapter Questions

Problem 20P: Julie James is opening a lemonade stand. She believes the fixed cost per week of running the stand...

Related questions

Question

100%

Please solve the linear equation (LP) with clear steps and explanation

Transcribed Image Text:Problem 1:

A manufacturer of engine parts produces valves and pistons at its main plant. Both

parts are processed by the Machining Department and by the Finishing Department.

Each valve requires 0.4 hours of machining time and 0.3 hours of finishing time, and

each piston requires 0.3 hours of machining and 0.5 hours of finishing. The production

process also requires 2 pounds of steel for each part.

In drawing up a schedule for the coming month the plant manager knows that 300

hours of production time will be available in the Machining Department and 400 hours

will be available in the Finishing Department. In addition, existing contracts provide for

the delivery of 1800 pounds of steel during the month.

The market for valves and pistons is competitive, and the company can sell all the parts

it produces during the month. At current prices the gross profit on each valve sold is

OR3, while for each piston sold the gross profit is OR4. The plant manager would like to

find a production plan for the month that will maximise profits.

Determine the optimal plan and the maximum possible profit.

Expert Solution

Step 1 Given the following information in the question:

Step by step

Solved in 4 steps with 4 images

Recommended textbooks for you

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:

9781285869681

Author:

Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:

Cengage Learning

Production and Operations Analysis, Seventh Editi…

Operations Management

ISBN:

9781478623069

Author:

Steven Nahmias, Tava Lennon Olsen

Publisher:

Waveland Press, Inc.