Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN: 9781259696527

Author: J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher: McGraw-Hill Education

expand_more

expand_more

format_list_bulleted

Question

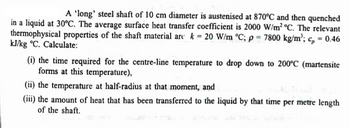

Transcribed Image Text:A 'long' steel shaft of 10 cm diameter is austenised at 870°C and then quenched

in a liquid at 30°C. The average surface heat transfer coefficient is 2000 W/m² °C. The relevant

thermophysical properties of the shaft material are k = 20 W/m °C; p = 7800 kg/m³; c = 0.46

kJ/kg °C. Calculate:

(i) the time required for the centre-line temperature to drop down to 200°C (martensite

forms at this temperature),

(ii) the temperature at half-radius at that moment, and

(iii) the amount of heat that has been transferred to the liquid by that time per metre length

of the shaft.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 8 steps with 7 images

Knowledge Booster

Similar questions

- A 2 inch Schedule 40 pipe carrying hot fluid coated with insulation 2 cm thick. The conductivity of this insulation k = 0.06 W / m.K. This insulation is useful for reducing heat. The inner diameter and outer diameter of the pipe are 5.25 cm and 6.03 cm, respectively. The inner surface temperature of the pipe is 150 ° C and the outer surface temperature of the insulation is 25 ° C. Pipe conductivity = 43 W / m.K. Calculate: a. Heat transfer rate per m pipe length b. Pipe outer surface temperaturearrow_forwardA 5 cm thick steel pipe, 1.0 m long, with an internal diameter of 8 cm is covered with 4 cm thick insulation. The inside wall temperature of the steel pipe is 100°C. The ambient temperature around the insulated pipe is 24°C. The convective heat-transfer coeffi cient on the outer insulated surface is 50 W/(m² K). Calculate the temperature at the steel insulation interface. The thermal conductivity of steel is 54 W/(m K), and the thermal conductivity of insulation is 0.04 W/(m K).arrow_forwardLiquid food is heated in a tubular heat exchanger. The inner pipe wall temperature is 110 ° C. The internal diameter of the pipe is 40 mm. Product flows at 0.7 kg / s. If the initial temperature of the product is 7 ° C, calculate the convective heat transfer coefficient. The thermal properties of the product are as follows: specific heat = 3.7 kJ / (kg ° C), thermal conductivity = 0.6 W / (m ° C), product viscosity = 500 x 10-6 Pa s, density = 1000 kg / m³ , the product viscosity at 110 ° C = 410 x 10-6 Pa s. a. Find the Reynold number = Answer. b. Find the number Prantl = Answer. c. Find the Nuselt = Answer number d. Convection coefficient = AnswerW / m² ° C.arrow_forward

- Steel pipe 3 cm thick, 1.0 m long and 10 cm deep, covered with 6 cm thick insulation. The wall temperature in the steel pipe is 100 ° C. The ambient temperature around the insulated pipe is 24 ° C. The convection heat transfer coefficient outside the insulation surface is 50 W / (m² K). The thermal conductivity of steel is 54 W / (m K), and the thermal conductivity of the insulation is 0.04 W / (m K). Count; a. Heat loss per meter of pipe = Answer watt. b. Temperature between steel pipe and insulation. = Answer ° C.arrow_forward4arrow_forwardAir at 25 ° C blows over the hot steel plate whose surface temperature is maintained at 200 ° C. The plates have dimensions of 50 cm x 50 cm and a thickness of 2.5 cm. The convection heat transfer coefficient on the upper surface is 25 W / (m² ° C). The thermal conductivity of steel is 45 W / (m ° C). Calculate the hourly heat loss from the plate surface. a. heat loss per hour = AnswerkJ. b. If the reverse side surface temperature is maintained, specify hourly heat loss = AnswerkJ.arrow_forward

- for chemical engineersarrow_forwardA plane wall has a thermal conductivity of 20 W/(m-K) and generates heat at 0.5 MW/m3. The wall is 0.2 meters thick and is perfectly insulated on one side. The other side is exposed to fluid at 100 °C. The convective heat transfer coefficient between the wall and the fluid is 400 W/(m2 K). Determine the maximum temperature in the wall.arrow_forwardThe exhaust duct from a heater has an inside diameter of 114.3 mm with ceramic walls 6.4 mm thick. The average k=1.52 W/m· K. Outside this wall, an insulation or rock wool 102 mm thick is installed. The thermal conductivity of the rock wool is k= 0.046+ 1.56 x 104 T°C (W/m · K). The inside surface * = temperature of the ceramic is T1 = 588.7 K, and the outside surface temperature of the insulation is 311 K. Calculate the heat loss for 1.5 m of duct and the interface temperature T2 between the ceramic and the insulation. [Hint: The correct value of km for the insulation is that evaluated at the mean temperature of (T2 + T3)/2. Hence, for the first trial assume a mean temperature of, say, 448 K. Then calculate the heat loss and T2 Using this new T2, calculate a new mean temperature and proceed as before.]arrow_forward

- 2-2 A certain material 2.5 cm thick, with a cross-sectional area of 0.1 m², has one side maintained at 35°C and the other at 95°C. The temperature at the center plane of the material is 62°C, and the heat flow through the material is 1 kW. Obtain an expression for the thermal conductivity of the material as a function of temperature.arrow_forwardA cylindrical container is being designed to contain an exothermic chemical reaction. The container has an external diameter of 80 mm and is 0.2 m tall. The temperature of the cylinder must not exceed 500 °C. To improve cooling of the container, fins of thickness t=5 mm and length L= 40 mm are spaced at least 10 mm apart. Each fin has an efficiency of n= 40%. The ambient temperature is maintained at 22 °c and the heat transfer coefficient between the ambient air and the cylinder is 50 W/m2K. If the chemical reaction produces a maximum of 3.2 kW per kilogram of substance, the maximum mass of substance which can safely be processed in the container to 2 decimal places is kg. The effectiveness of each fin to 1 decimal place is You may neglect heat transfer from the tips of the fins and from the circular surfaces of the cylinder.arrow_forward.240mm steam main pipe, 210m long is covered with 50mm of high temperature insulation (k-0.092 W/m °C) and 40mm of low temperature insulation (k-0.062 W/m °C). The inner and the outer surface temperature as measured are 390 °C and 40 °C respectively. Calculate: 1- The total heat loss per hour. 2- The temperature between two layers of insulation.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Introduction to Chemical Engineering Thermodynami...

Chemical Engineering

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind...

Chemical Engineering

ISBN:9781118431221

Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:WILEY

Elements of Chemical Reaction Engineering (5th Ed...

Chemical Engineering

ISBN:9780133887518

Author:H. Scott Fogler

Publisher:Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:9781285061238

Author:Lokensgard, Erik

Publisher:Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:9780072848236

Author:Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:McGraw-Hill Companies, The