Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

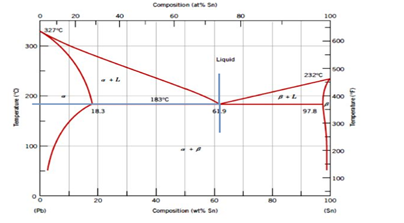

A lead-tin (Pb-Sn) alloy of composition 30 wt % Sn and 70 wt % Pb is slowly heated from a temperature of 140 OC. Refer to the phase diagram provided in Figure 1 and answer the following.

(i) At what temperature does the first liquid phase form?

(ii) What is the composition of this liquid phase?

(iii) At what temperature does complete melting of the alloy occur?

(iv) What is the composition of the last solid remaining prior to complete melting?

Transcribed Image Text:Composition (at% Sn)

20

40

60

80

100

327°C

600

300

Liquid

500

232°C

a + L

200

ß + L

400

183°C

18.3

61.9

97.8

300

100

a + B

200

100

20

40

60

100

(Pb)

Composition (wt% Sn)

(Sn)

Temperature (°C)

80

Temperature (°F)

Expert Solution

arrow_forward

Step 1

From the given figure, the first phase liquid form occurs at 184ͦ C which is where the eutectic isotherm is intersected by a vertical line of the composition.

Trending nowThis is a popular solution!

Step by stepSolved in 4 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Referring to Figure 1, please answer the following [NOTE: SHOW YOUR WORK on Figure 1]:a. provide the specific name for the phase boundary lines denoted by A and B. b. identify the phases present at equilibrium in the phase fields denoted by C, D, and E. c. identify the specific name for the point denoted by F. d. What is the maximum solid solubility of Mg in Al? At what temperature does it occur? e. An Al-Mg alloy (10 wt% Mg, 90 wt% Al) is heated slowly (to insure equilibrium) from a temperature of 200 C: i. At what temperature does the first liquid phase form? ii. What is the composition of the liquid phase at the temperature in part i.? iii. At what temperature does complete melting (no solid phase remaining) occur? iv. What is the composition of the last solid remaining prior to complete melting? f. Using the equilibrium phase diagram of Figure 1, identify the phases present, their compositions, and their relative mass fractions at equilibrium for a 70 wt% Mg – 30 wt% Al…arrow_forwardGiven the equilibrium phase diagram (a) below, briefly describe the mechanisms of precipitation hardening/strengthening of an aluminium alloy making reference to the transitions shown in (b) below to X, X to A, X to D, A to B and A to C. а +0 D B Time (a) (b) - anedua Temperaturearrow_forwardIs it possible to have a copper-nickel alloy that, at equilibrium, consists of a liquid phase of composition 20 wt% Ni-80 wt% Cu and also an a phase of composition 37 wt% Ni-63 wt% Cu? If so, what will be the approximate temperature of the alloy? If this is not possible, explain why. Temperature (°C) 1600 1500 1400 1300 1200 1100 1000 0 1085°C (Cu) 20 Liquid Liquidus line L B 40 a+L a A 60 Composition (wt% Ni) (a) 1455°C Solidus line 80 2800 2600 2400 2200 2000 100 (Ni) Temperature (°F) Temperature (°C) 1300 1200 20 Liquid Tie line. a + Liquid a 1 KR I 1 1 B ↑ Co a + Liquid -S 30 CL Composition (wt% Ni) (b) 40 1 Ca a 50arrow_forward

- For the lead-tin system:(a) Determine the proportions of liquid and solid phases for the 40% Sn composition ofthe lead-tin system at temperatures 2500?, 2000?, ??? 1500?. (b) Draw the development of microstructure along the dashed line at points A,B,C, andD.arrow_forwardCorrect and complete solution pleasearrow_forwardMaterial science Assuming this system forms a laminar type eutectic, determine the volume proportion of phases for an equilibrium solidified 50% Pb alloy. Sketch the expected microstructure.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY