Financial Accounting Intro Concepts Meth/Uses

14th Edition

ISBN: 9781285595047

Author: Weil

Publisher: Cengage

expand_more

expand_more

format_list_bulleted

Question

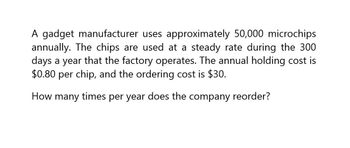

How many times per year does the company reorder of this financial accounting question?

Transcribed Image Text:A gadget manufacturer uses approximately 50,000 microchips

annually. The chips are used at a steady rate during the 300

days a year that the factory operates. The annual holding cost is

$0.80 per chip, and the ordering cost is $30.

How many times per year does the company reorder?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps

Knowledge Booster

Similar questions

- Elliott, Inc., has four salaried clerks to process purchase orders. Each clerk is paid a salary of 25,750 and is capable of processing as many as 6,500 purchase orders per year. Each clerk uses a PC and laser printer in processing orders. Time available on each PC system is sufficient to process 6,500 orders per year. The cost of each PC system is 1,100 per year. In addition to the salaries, Elliott spends 27,560 for forms, postage, and other supplies (assuming 26,000 purchase orders are processed). During the year, 25,350 orders were processed. Required: 1. Classify the resources associated with purchasing as (1) flexible or (2) committed. 2. Compute the total activity availability, and break this into activity usage and unused activity. 3. Calculate the total cost of resources supplied (activity cost), and break this into the cost of activity used and the cost of unused activity. 4. (a) Suppose that a large special order will cause an additional 500 purchase orders. What purchasing costs are relevant? By how much will purchasing costs increase if the order is accepted? (b) Suppose that the special order causes 700 additional purchase orders. How will your answer to (a) change?arrow_forwardPlease answer the general accounting questionarrow_forwardA local bakery sells 12,000 loaves of sourdough bread each year. The loaves are ordered from an outside supplier, and it takes 4 days for each shipment of loaves to arrive. Ordering costs are estimated at $18 per order. Carrying costs are $6 per loaf per year. Assume that the bakery is open 300 days a year. What is the maximum inventory of loaves held in a given ordering cycle? a. 180.02 b. 362.07 c. 268.33 d. 152.98arrow_forward

- A local distributor for a national tire company expects to sell approximately 9,600 steel-belted radial tires of a certain size and tread design next year. Annual carrying costs are $16 per tire, and ordering costs are $75. The distributor operates 288 days a year. Determine the EOQ How many times per year does the store reorder? Determine the length of an order cyclearrow_forwardThe General Chemical Company uses 150,000 gallons of hydrochloric acid per month. The cost of carrying the chemical in inventory is 50 cents per gallon per year, and the cost of ordering the chemical is $150 per order. The firm uses the chemical at a constant rate throughout the year. It takes 18 days to receive an order once it is placed. The reorder point is ________.arrow_forwardWhat is the maximum inventory of croissants held in a given ordering cycle of this financial accounting question?arrow_forward

- The Warren W. Fisher Computer Corporation purchases 8,000 transistors each year as components inminicomputers. The unit cost of each transistor is $10, and the cost of carrying one transistor in inventoryfor a year is $3. Ordering cost is $30 per order and finds that deliveries from his supplier generally take 5working days. What are?(a) the optimal order quantity.(b) the expected number of orders placed each year.(c) the expected time between orders? Assume that Fisher operates on a 200-day working year.(d) the reorder point for the transistors.arrow_forwardWhat is the maximum inventory?arrow_forwardAn auto parts supplier sells batteries to car dealers and auto mechanics. The annual demand is approximately 1,200 batteries. The suppliers pays $28 for each battery and estimates that the annual holding cost is $8.40 per year. It costs approximately $20 to place an order. Assume a 250-day working year. a. Compute for the EOQ round off your answer to the nearest whole number. b. Compute for the expected number of orders. Round off your answer to the nearest whole number. c. Compute for the expected time between orders. Round off your answer to the nearest whole number.arrow_forward

- What is the number of workdays in an order cycle?arrow_forwardHelparrow_forwardA liquor warehouse expects to sell 10,000 bottles of scotch whiskey in a year. Each bottle costs $14, plus a fixed charge of $125 per order. If it costs $10 to store a bottle for a year, how many bottles should be ordered at a time and how many orders should the warehouse place in a year to minimize inventory costs? bottles per order orders per yeararrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning

Cornerstones of Cost Management (Cornerstones Ser...

Accounting

ISBN:9781305970663

Author:Don R. Hansen, Maryanne M. Mowen

Publisher:Cengage Learning