Elements Of Electromagnetics

7th Edition

ISBN: 9780190698614

Author: Sadiku, Matthew N. O.

Publisher: Oxford University Press

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

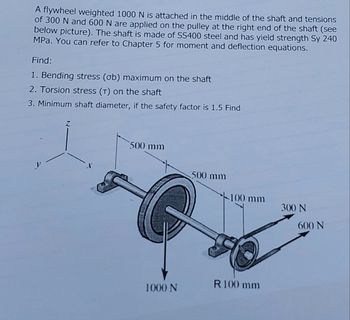

A flywheel weighted 1000 N is attached in the middle of the shaft and tensions of 300 N and 600 N are applied on the pulley at the right end of the shaft (see below picture). The shaft is made of SS400 steel and has yield strength Sy 240 MPa. You can refer to Chapter 5 for moment and deflection equations.

Find:

1. Bending stress (ob) maximum on the shaft

2. Torsion stress (T) on the shaft

3. Minimum shaft diameter, if the safety factor is 1.5 Find

500 mm

500 mm

100 mm

300 N

600 N

Transcribed Image Text:A flywheel weighted 1000 N is attached in the middle of the shaft and tensions

of 300 N and 600 N are applied on the pulley at the right end of the shaft (see

below picture). The shaft is made of SS400 steel and has yield strength Sy 240

MPa. You can refer to Chapter 5 for moment and deflection equations.

Find:

1. Bending stress (ob) maximum on the shaft

2. Torsion stress (T) on the shaft

3. Minimum shaft diameter, if the safety factor is 1.5 Find

500 mm

1000 N

.500 mm

100 mm

R100 mm

300 N

600 N

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 3 steps with 5 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- A 38-mm-diameter solid steel shaft supports loads PA = 1230 N and Pc = 2170 N, as shown. Assume LAB = 82 mm, LBc = 203 mm, and LCD = 152 mm. The bearing at B can be idealized as a roller support and the bearing at D can be idealized as a pin support. Determine the magnitude omax and location x (measured positive to the left from D) of the maximum bending stress in the shaft. Answers: o max || PA LAB B LBC MPa, x = C Pc LCD D mm.arrow_forwardThe built-up beam is subjected to a moment of M = 80 kNm. Variable d₁ d₂ d3 da Values for the figure are given in the following table. Note the figure may not be to scale. d5 d3 de d₁ Value 128 mm 22 mm 276 mm 11 mm 138 mm d4 12 mm M₁ de d5 a. Determine the distance from the Neutral Axis to the top of the beam, N.A. b. Determine the mass moment of inertia of the beam, I. Determine the max compressive stress acting on the beam, compression c. d. Determine the max tensile stress acting on the beam, tension.arrow_forwardSolve using DIM. Previous answer here was wrong so please correct it.arrow_forward

- A beam has a bending moment of 3.5 kN-m applied to a section with a hollow circular cross-section of external diameter 3 cm and internal diameter 2.3 cm . The modulus of elasticity for the material is 210 x 109 N/m2. Calculate the radius of curvature and maximum bending stress. Also, calculate the stress at the point at 0.6 cm from the neutral axis (i) The moment of inertia in (mm^4)= ii) The radius of curvature in (mm) = (iii) The maximum bending stress in (N/mm^2)= iv) The bending stress at the point 0.6 cm from the neutral axis in (N/mm^2)=arrow_forwardes A gear reduction unit uses the countershaft shown in the figure. Gear A receives power from another gear with the transmitted force FA applied at the 20° pressure angle as shown. The power is transmitted through the shaft and delivered through gear B through a transmitted force Fg at the pressure angle shown. For the steel countershaft specified in the table, find the deflection and slope of the shaft at point A. Use superposition with the deflection equations in Table A-9. Assume the bearings constitute simple supports. In the figure below, FA is 310 lbf and the diameter of the shaft (dshaft) is 1.29 in. dshaft Gear A 20-in dia. 16 in FA 20⁰ The deflection at point A is The slope at point A is 14 in 100 Gear B 8-in dia. rad. 9 in in. B FB 20°arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY