Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

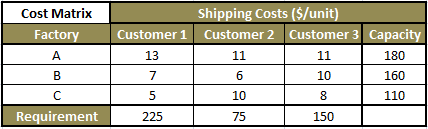

A firm is attempting to minimize its shipping costs. The firm has 3 factories and must supply the needs of its 3 customers without shortages. Since the firm has no storage facilities, each factory must make daily shipments to its customers. The table below shows the capacity of each factory, the amount required by each customer, and the cost of shipping from each factory to each customer.

| Shipping Costs ($/unit) | |||||||||

| Factory/Capacity | Customer 1 | Customer 2 | Customer 3 | ||||||

| A/180 units | 13 | 11 | 11 | ||||||

| B/160 units | 7 | 6 | 10 | ||||||

| C/110 units | 5 | 10 | 8 | ||||||

| Requirement— | 225 | units | Requirement— | 75 | units | Requirement— | 150 | units | |

Complete the table below to show the quantity shipped from each factory to each customer. (Leave no cells blank - be certain to enter "0" wherever required.)

What is the total cost of meeting customer requirements each day?

Expert Solution

arrow_forward

Step 1

Given-

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 6 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, operations-management and related others by exploring similar questions and additional content below.Similar questions

- "A chipboard company has 4 factories, Mazatenango, Retalhuleu, Escuintla and Xela. It has four major distributors of its chipboards, which are distributor 1, distributor 2, distributor 3 and distributor 4: Mazatenango Retalhuleu Escuintla Xela DEMAND D1 10 16 19 12 350 D2 12 10 18 15 300 D3 15 22 10 10 250 D4 20 10 12 20 200 SUPPLY 150 150 350 250 1) Formulate the problem as a transportation problem, solve it with the three methods and find the optimal cost for this problem. methods and find the optimal cost for this transportation problem. (remember to go through all possible routes). IN THIS CASE USE MINIMUM TRANSPORTATION COST - LEAST COST METHODarrow_forwardThe following table represents the cost to ship from Distribution Center 1, 2, or 3 to Customer A, B, or C. Is this a "balanced" or "unbalanced" model? Customer B 6 DC 1 2 3 Demand. Obalanced. A 4 5 3 200 2 5 350 unbalanced O not enough information. O equal sources and destinations C 8 7 9 400 Supply 500 400 300arrow_forward(Problem 1) A manager of Drexel Clothing Company has to make a decision on shipping. There are two shippers, A and B. Both offer a two-day rate: A for $500 and B for $525. In addition, A offers a three-day rate of $450 and a nine-day rate of $325 and B offers a four-day rate of $400 and a seven-day rate for $375. Annual holding costs are 25% of unit price. Four hundred boxes are to be shipped, and each box has a price of $250. The shipping charges are for the entire batch of 400 boxes. Which shipping alternative would you recommend? Explain.arrow_forward

- 2. By using the data below, use a transportation method to : COST in $ Assembly Plant Supply 210 Factory 2 A 8 9 400 10 6 12 8 190 Demand 120 620 60 A. Formulate this linear programming model B. If you are using VAM and NorthWest corner method, which solution is the best and how much is the best total cost ?arrow_forward14. Toyco produces a line of Bonnie dolls and accessories at its plants in New York and Baltimore that must be shipped to distribution centers in Chicago and Los Angeles. The company uses Air Freight, Ic., to make its shipments. Suppose that it can ship directly or through Pittsburgh and Denver. The daily production rates at the plants are respectively 5,000 and 7,000 units daily, and the demands at the dis- tribution centers are respectively 3,500 and 8,500 units daily. The costs of shipping 1,000 units are given in the following table. Find the optimal shipping routes and the associated cost. то Pittsburgh Denver Chicago Los Angeles $182 77 F New York Baltimore $375 290 275 $285 245 125 $460 575 380 R Pittsburgh M Denver 90 110arrow_forwardSusan manages the packaging supplies for the New Zealand distributorship of AllBirds product lines. It;s her job to order all the shoe boxes that house each pair of shoes (whether going to retail stores, or shipping directly to consumers via the online store). She purchases shoe boxes from a local printing supplier. The NZ distributor ships on average 325 boxes of shoes each month. Boxes cost $2.25 each, and each order costs $18 to process. Because of limited storage space, Susan's manager wants to charge inventory holding at 25% of the unit cost. The lead time is 7 days. Assume 360 working days per year. Calculate the following: a. Economic order Wuantity b. Reorder Point (assuming no safety stocks) c.Number of orders-per-Year d.Total annual cost e.If storage space was so limited, Susan estimates that inventory holding cots would only be 15% of unit cost. How would that change total annual costs?arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.