Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

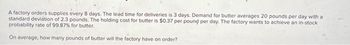

Transcribed Image Text:A factory orders supplies every 8 days. The lead time for deliveries is 3 days. Demand for butter averages 20 pounds per day with a

standard deviation of 2.3 pounds. The holding cost for butter is $0.37 per pound per day. The factory wants to achieve an in-stock

probability rate of 99.87% for butter.

On average, how many pounds of butter will the factory have on order?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 3 steps with 3 images

Knowledge Booster

Similar questions

- Please do not give solution in image format thankuarrow_forwardPlease answer questions 9 and 10 based on this data. Daily demand for packages of five videotapes at a warehouse store is found to be normally distributed with a mean of 50 and a standard deviation of 5. When the store orders more tapes, the orders take four days to arrive. Assume the store is open 360 days a year. If the store wants the probability of stocking out to be no more than 5%, and demand each day is independent of the day before, what should be the safety stock? Please round your answer to two decimals. Safety stock= 17 Question 10 4 pts If the store wants the probability of stocking out to be no more than 5%, and demand each day is independent of the day before, what reorder point should be set? Please round your answer to two decimals. Reorder point=arrow_forwardDaily demand for a product is 10 units. The standard deviation of demand during the review and lead time is 20 units. The review period is 30 days and the lead time is 14 days. At the time of review there are 150 units in stock. If the probability of stockout should not exceed 2%, how many units should be ordered?arrow_forward

- A health and nutrition store stocks a multivitamin with an annual demand of 1,000 bottles has Co probability distribution with μ = 25 and σ = 5. (a) What is the recommended order quantity? (Round your answer to the nearest integer.) = $23.50 and C = $9. The demand exhibits some variability such that the lead-time demand follows a normal (b) What are the reorder point and safety stock if the store desires at most a 4% probability of stock-out on any given order cycle? (Round your answers to the nearest integer.) reorder point safety stock (c) If a manager sets the reorder point at 30, what is the probability of a stock-out on any given order cycle? (Round your answer to four decimal places.) How many times would you expect a stock-out during the year if this reorder point were used? (Round your answer to the nearest integer.)arrow_forwardA retailer has two stores selling the same product. Weekly demand at store 1 is normally distributed with a mean of 100 and a standard deviation of 10, while weekly demand at store 2 is normally distributed with a mean of 150 and a standard deviation of 25. Demand at the two stores is independent. The retailer orders from a supplier with a 1 week lead time using a periodic review policy with a review period of 1 week, and targets a 95% service level. If the retailer wants to centralize inventory across the two stores, i.e., hold just one stock of inventory to serve demand from both stores, what should the order-up-to level be? PLEASE SHOW CALCULATIONarrow_forwardAAA auto supply store sells snow tires which are ordered every Friday to meet next week's demand. The sales price for the most popular size is $50 per tire and its cost for AAA is $35. If too many tires are ordered AAA incurs an inventory carrying cost of $2 per tire. If AAA is out of stock, it forgoes the profits from missed sales. AAA has the option to order 100, 150, or 200 tires to meet next week's demand which can be either 100, 150, or 200 tires.Based on its historical demand distribution, assume that AAA Inc. has determined the followingprobability information: P(100) = 0.4, P(150) = 0.3, and P(200) = 0.3 e. Which alternative should be chosen based on the minimax regret criterion? f. Which alternative should be chosen using the expected monetary value (EMV) criterion? g. What is the expected value under perfect information (EVPI)? Show Workarrow_forward

- A food processor purchases corn for use in its products. The firm uses 700 pounds of corn per week and purchases corn for $0.45 per pound from a supplier. The cost to hold one pound of corn in inventory for one year is $0.09. Each time the firm orders corn from the supplier, the firm must pay a $48 order processing charge. Assume there are 52 weeks in a year and round your answer to the nearest integer value. What is the optimal order quantity (in pounds)? poundsarrow_forwardAndy's Auto Dealership (AAD) is a family-run auto dealership selling both new and used vehicles. In an average month, AAD sells a total of 160 vehicles. New vehicles represent 60 percent of sales, and used vehicles represent 40 percent of sales. Max has recently taken over the business from his father. His father always emphasized the importance of carefully managing the dealership's inventory. Inventory financing was a significant expense for AAD. Max's father consequently taught him to keep inventory turns as high as possible. Examining the dealership's performance over recent years, Max discovered that AAD had been turning its inventory (including both new and used vehicles) at a rate of 8 times per year. What is AAD's average inventory (including both new and used vehicles)? Drilling down into the numbers, Max has determined that the dealerships new and used businesses appear to behave differently. He has determined that turns of new vehicles are 7.2 per year, while turns of used…arrow_forwardA manufacturing plant procures 100,000 filters per year. Each unit has a fixed order cost is $50. To maintain the inventory in optimal conditions, there is a carrying cost rate of 10% per year. The vendor of filters has offered the following price breaks: for orders of more than 5,000 filters, cost is $4.50/unit; for orders between 1,000 and 5,000 filters, cost is $4.75/unit; orders less than 1,000 filters have a cost of $5.00/unit. Find the economic order quantity. Calculate the average annual cost for the optimal solution.arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.