Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

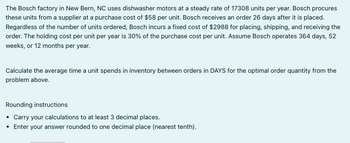

Transcribed Image Text:The Bosch factory in New Bern, NC uses dishwasher motors at a steady rate of 17308 units per year. Bosch procures

these units from a supplier at a purchase cost of $58 per unit. Bosch receives an order 26 days after it is placed.

Regardless of the number of units ordered, Bosch incurs a fixed cost of $2988 for placing, shipping, and receiving the

order. The holding cost per unit per year is 30% of the purchase cost per unit. Assume Bosch operates 364 days, 52

weeks, or 12 months per year.

Calculate the average time a unit spends in inventory between orders in DAYS for the optimal order quantity from the

problem above.

Rounding instructions

• Carry your calculations to at least 3 decimal places.

• Enter your answer rounded to one decimal place (nearest tenth).

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps

Knowledge Booster

Similar questions

- What are the primary components of the Wilson approach, and how do they contribute to inventory optimization?arrow_forwardAnnual demand for squash racquets is 50,000 units, and carrying costs amount to P2 per unit. Order costs for the company amount to P5. The optimum order quantity in units for squash racquets is (rounded to the nearest unit):arrow_forwardExamine recent advancements or variations of the Wilson approach and their implications for inventory optimization in today's dynamic business environment.arrow_forward

- Subject: Materials Management and Inventory Systems Note:- Do not provide handwritten solution. Maintain accuracy and quality in your answer. Take care of plagiarism. Answer completely. You will get up vote for sure.arrow_forwardA golf specialty wholesaler operates 50 weeks per year. Management is trying to determine an inventory policy for its 1-irons, which have the following characteristics: Demand (D) = 2,000 units/year, normally distributed Standard deviation of weekly demand = 3 units Ordering cost = $ 50 /order Holding cost (H) = $ 6.00/unit per year Desired service level = 90 % Lead time (L) = 5 weeks If the company uses a periodic review system, what should the review period (P) be (in weeks)? Pick the closest answer.arrow_forwardInventory management and demand planning at Dell The computer company Dell has long been seen as one of the most agile businesses in the industry. The success of Dell is in large part due to its highly responsive supply chain, which is capable of building and delivering customized products in a matter of days with minimal inventory. Dell’s ability to operate a build-to-order strategy is based partly on the modular design of many of their products but more particularly on a very high level of synchronization with their suppliers. There is a high level of visibility across the Dell supply chain with suppliers receiving information on Dell’s order book every two hours. Ahead of this information, suppliers are provided with capacity forecasts from Dell to enable them to produce at a rate that is planned to match actual demand. Each of Dell’s factories is served from a ‘vendor hub’, operated by third- party logistics service providers, the purpose of which is to keep a buffer of inventory…arrow_forward

- Inventory Planning in Procter & Gamble– Advantages and Disadvantagesarrow_forwardEvaluate the ethical considerations involved in inventory optimization, including its social and environmental implications.arrow_forwardWhat is the reason for a manufacturing organization to need three separate types of inventory?arrow_forward

- Develop a EOQ solution and calculate total relevant costs for the gross requirements in the following table*. Period 1 2 3 4 5 6 7 8 9 10 11 12 Gross requirements 20 30 30 30 20 10 40 60 *Holding cost =$ 2.50/unit/week; setup cost =$ 150; lead time =1 week; beginning inventory =40. What is the average demand per week? with 2 decimal places): Calculate Economic Order Quantity (EOQ) Develop a EOQ solution (enter your responses as whole numbers). Period 1 2 3 4 5 6 7 8 9 10 11 12 Gross requirements 20 30 30 30 20 10 40 60 Scheduled receipt…arrow_forwardIf Sarah wants to minimize inventory holding and ordering costs, how much Palm oil should she purchase with each order (in kgs)?arrow_forwardKGU company sells shoes whose daily demand is 100 units. The inventory holding cost is $2 per unit per year. The company also spends $20 per unit to process order. It takes 6 days from the time of reorder to the stocking of the inventory. The company keeps a safety stock that can cover twice the inventory. What is the ideal order quantity for KGU to purchase to minimize inventory costs? What is the ideal level of inventory at which KGU should pace a purchase order?arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.