Cornerstones of Cost Management (Cornerstones Series)

4th Edition

ISBN: 9781305970663

Author: Don R. Hansen, Maryanne M. Mowen

Publisher: Cengage Learning

expand_more

expand_more

format_list_bulleted

Question

Subject - account

Please help me.

Thankyou.

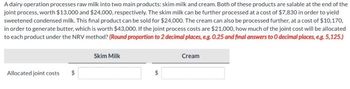

Transcribed Image Text:A dairy operation processes raw milk into two main products: skim milk and cream. Both of these products are salable at the end of the

joint process, worth $13,000 and $24,000, respectively. The skim milk can be further processed at a cost of $7,830 in order to yield

sweetened condensed milk. This final product can be sold for $24,000. The cream can also be processed further, at a cost of $10,170,

in order to generate butter, which is worth $43,000. If the joint process costs are $21,000, how much of the joint cost will be allocated

to each product under the NRV method? (Round proportion to 2 decimal places, e.g. 0.25 and final answers to 0 decimal places, e.g. 5,125.)

Allocated joint costs

Skim Milk

Cream

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, accounting and related others by exploring similar questions and additional content below.Similar questions

- Memanarrow_forwardCarina Company produces sanitation products after processing specialized chemicals; Thefollowing relates to its activities: 1 Kilogram of chemicals purchased for $2000 and with an additional $1000 isprocessed into 400 grams of Crystals and 80 litres of a Cleaning agent. At split-off, agram of Crystal can be sold for $1 and the Cleaning agent can be sold for $4 per litre. At an additional cost of $400, Carina can process the 400 grams of Crystal into 500 grams of Detergent that can be sold for $2 per gram. The 80 litres of Cleaning agent is packaged at an additional cost of $300 and made into 200 packs of Softener that can be sold for $2 per pack. Required: 1. Allocate the joint cost to the Detergent and the Softener using the following: a. Sales value at split-off method b. NRV method 2. Should Carina have processed each of the products further? What effect does the allocationmethod have on this decision? Make full references to Question 1 when possiblearrow_forwardIsaac Corporation processes sugar beets in batches that it purchases from farmers for $47 a batch. A batch of sugar beets costs $14 to crush in the company's plant. Two intermediate products, beet fiber and beet juice, emerge from the crushing process. The beet fiber can be sold as is for $22 or processed further for $13 to make the end product industrial fiber that is sold for $31. The beet juice can be sold as is for $45 or processed further for $27 to make the end product refined sugar that is sold for $67. Which of the intermediate products should be processed further? A. beet fiber should NOT be processed into industrial fiber; beet juice should NOT be processed into refined sugar B. beet fiber should NOT be processed into industrial fiber; beet juice should be processed into refined sugar C. beet fiber should be processed into industrial fiber; beet juice should NOT be processed into refined sugar D. beet fiber should be processed into industrial fiber; beet juice should be…arrow_forward

- Carina Company produces sanitation products after processing specialized chemicals; Thefollowing relates to its activities: 1 Kilogram of chemicals purchased for $2000 and with an additional $1000 isprocessed into 400 grams of Crystals and 80 litres of a Cleaning agent. At split-off, agram of Crystal can be sold for $1 and the Cleaning agent can be sold for $4 per litre.2. At an additional cost of $400, Carina can process the 400 grams of Crystal into 500grams of Detergent that can be sold for $2 per gram. The 80 litres of Cleaning agent ispackaged at an additional cost of $300 and made into 200 packs of Softener that canbe sold for $2 per pack.Required:1. Allocate the joint cost to the Detergent and the Softener using the following:a. Sales value at split-off method b. NRV method 2. Should Carina have processed each of the products further? What effect does the allocationmethod have on this decision?arrow_forwardCider Hill Farm is a producer of milk and byproducts. A single production process at Cider Hill Farm yields milkas the main product, as well as ghee, a byproduct of milk production, that can be sold. Both products are fullyprocessed by the splitoff point, and there are no separable costs. For the month of October 2020, the cost ofoperations is $335,000.Production and sales data are as follows: Cider Hill Farm is a producer of milk and byproducts. A single production process at Cider Hill Farm yields milk as the main product, as well as ghee, a byproduct of milk production, that can be sold. Both products are fully processed by the splitoff point, and there are no separable costs. For the month of October 2020, the cost of operations is $335,000. Production and sales data are as follows: (Click the icon to view the production and sales data.) There were no beginning inventories on October 1, 2020. Read the requirements Requirement 1. What is the gross margin for Cider Hill Farm under…arrow_forwardAnswer please...!arrow_forward

- Rise N’ Shine Coffee Company produces Columbian coffee in batches of 4,000 pounds. The standard quantity of materials required in the process is 4,000 pounds, which cost $5.73 per pound. Columbian coffee can be sold without further processing for $9.02 per pound. Columbian coffee can also be processed further to yield Decaf Columbian, which can be sold for $11.60 per pound. The processing into Decaf Columbian requires additional processing costs of $7,012 per batch. The additional processing will also cause a 5% loss of product due to evaporation. Required: a. Prepare a differential analysis dated October 6 on whether to sell regular Columbian (Alternative 1) or process further into Decaf Columbian (Alternative 2). Refer to the Amount Descriptions list provided for the exact wording of the answer choices for text entries. For those boxes in which you must enter subtracted or negative numbers use a minus sign. b. Should Rise N’ Shine sell Columbian coffee or process further…arrow_forwardData table Milk Ghee, byproduct Production (in gallons) 580,000 13,000 Sales (in gallons) Selling Price per Gallon 556,800 $ 12,350 $ 1.00 0.60arrow_forwardYour Corporation processes sugar beets in batches. A batch of sugar beets costs $625 to buy from farmers and $275 to crush in the company's plant. Two intermediate products, beet fiber (750 units) and beet juice (250 units), emerge from the crushing process. The beet fiber can be sold as is for $20 or processed further for $18 to make the end product industrial fiber that is sold for $45. The beet juice can be sold as is for $42 or processed further for $24 to make the end product refined sugar that is sold for $62. How much more profit (loss) does the company make by processing one batch of sugar beets into the end products industrial fiber and refined sugar? Group of answer choices $3,975 $6,000 $4,250 ($4,250) $5,250arrow_forward

- Healthy Eats produces three products from a single raw material. The total cost is $160,000 and the number of units for each product is as follows: Product A: 10,000 units Product B: 10,000 units Product C: 15,000 units Product A can be sold at the split-off point for $4 per unit, or it can be processed further at a cost of $25,000 and then sold for $10 per unit. Should product A be sold at the split-off point or processed further? Why?arrow_forwardKosakowski Corporation processes sugar beets in batches. A batch of sugar beets costs $66 to buy from farmers and $17 to crush in the company's plant. Two intermediate products, beet fiber and beet juice, emerge from the crushing process. The beet fiber can be sold as is for $23 or processed further for $13 to make the end product industrial fiber that is sold for $36. The beet juice can be sold as is for $42 or processed further for $20 to make the end product refined sugar that is sold for $84. How much more profit (loss) does the company make by processing one batch of sugar beets into the end products industrial fiber and refined sugar? Select one: a. $22 b. ($18) c. ($116) d. $4arrow_forwardSugar beets are batch-processed at Kosakowski Corporation. Farmers charge $66 for a batch of sugar beets, and the company's facility charges $17 to crush them. Beet fibre and juice, two intermediate products, are produced during the crushing process. The beet fibre may be sold for $23 if it is sold as is, or it can be processed further for $13 to produce industrial fibre, which can be sold for $36. The price of the beet juice is $42, or it can be processed further for $20 to create refined sugar, which is then sold for $84. How much more money does the business make (lose) while processing one batch of sugar beets into refined sugar and industrial fibre?a. $22b. ($18)c. ($116)d. $4arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning Excel Applications for Accounting PrinciplesAccountingISBN:9781111581565Author:Gaylord N. SmithPublisher:Cengage Learning

Excel Applications for Accounting PrinciplesAccountingISBN:9781111581565Author:Gaylord N. SmithPublisher:Cengage Learning Managerial AccountingAccountingISBN:9781337912020Author:Carl Warren, Ph.d. Cma William B. TaylerPublisher:South-Western College Pub

Managerial AccountingAccountingISBN:9781337912020Author:Carl Warren, Ph.d. Cma William B. TaylerPublisher:South-Western College Pub Financial And Managerial AccountingAccountingISBN:9781337902663Author:WARREN, Carl S.Publisher:Cengage Learning,

Financial And Managerial AccountingAccountingISBN:9781337902663Author:WARREN, Carl S.Publisher:Cengage Learning, Essentials of Business Analytics (MindTap Course ...StatisticsISBN:9781305627734Author:Jeffrey D. Camm, James J. Cochran, Michael J. Fry, Jeffrey W. Ohlmann, David R. AndersonPublisher:Cengage Learning

Essentials of Business Analytics (MindTap Course ...StatisticsISBN:9781305627734Author:Jeffrey D. Camm, James J. Cochran, Michael J. Fry, Jeffrey W. Ohlmann, David R. AndersonPublisher:Cengage Learning

Cornerstones of Cost Management (Cornerstones Ser...

Accounting

ISBN:9781305970663

Author:Don R. Hansen, Maryanne M. Mowen

Publisher:Cengage Learning

Excel Applications for Accounting Principles

Accounting

ISBN:9781111581565

Author:Gaylord N. Smith

Publisher:Cengage Learning

Managerial Accounting

Accounting

ISBN:9781337912020

Author:Carl Warren, Ph.d. Cma William B. Tayler

Publisher:South-Western College Pub

Financial And Managerial Accounting

Accounting

ISBN:9781337902663

Author:WARREN, Carl S.

Publisher:Cengage Learning,

Essentials of Business Analytics (MindTap Course ...

Statistics

ISBN:9781305627734

Author:Jeffrey D. Camm, James J. Cochran, Michael J. Fry, Jeffrey W. Ohlmann, David R. Anderson

Publisher:Cengage Learning