Sustainable Energy

2nd Edition

ISBN: 9781337551663

Author: DUNLAP, Richard A.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

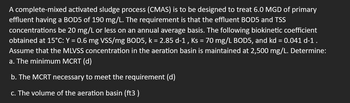

Transcribed Image Text:A complete-mixed activated sludge process (CMAS) is to be designed to treat 6.0 MGD of primary

effluent having a BOD5 of 190 mg/L. The requirement is that the effluent BOD5 and TSS

concentrations be 20 mg/L or less on an annual average basis. The following biokinetic coefficient

obtained at 15°C: Y = 0.6 mg VSS/mg BOD5, k = 2.85 d-1, Ks = 70 mg/L BOD5, and kd = 0.041 d-1.

Assume that the MLVSS concentration in the aeration basin is maintained at 2,500 mg/L. Determine:

a. The minimum MCRT (d)

b. The MCRT necessary to meet the requirement (d)

c. The volume of the aeration basin (ft3)

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 4 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, civil-engineering and related others by exploring similar questions and additional content below.Similar questions

- A hydrometer test has the following result: Gs = 2.65, temperature of water = 26 C, and L = 10.4 cm at 45 minutes after the start of sedimentation (see Figure 2.25). What is the diameter D of the smallest-size particles that have settled beyond the zone of measurement at that time (that is, t = 45 min)? Figure 2.25 ASTM 152H type of hydrometer placed inside the sedimentation cylinder (Courtesy of Khaled Sobhan, Florida Atlantic University, Boca Raton, Florida)arrow_forwardAn existing rural 4-lane highway is to be replaced by a 6-lane divided expressway (3 lanes in each direction). Traffic volume data on the highway indicate that the AADT (both directions) during the first year of operation is 24,000 with the following vehicle mix and axle loads. Passengercars=50percent 2-axle single-unit trucks (12,000lb/axle)=40percent 3-axle single-unit trucks (16,000lb/axle)=10percent The vehicle mix is expected to remain the same throughout the design life of 20 years, although traffic is expected to grow at a rate of 3.5 percent annually. Using the AASHTO design procedure, determine the minimum depth of concrete pavement required for the design period of 20 years. Pi=4.5J=3.2Pt=2.5Cd=1.0Sc=650lb/in.2So=0.3Ec=5106lb/in.2R=95k=130lb/in.3arrow_forwardA sand has Gs = 2.66. Calculate the hydraulic gradient that will cause boiling for e = 0.35, 0.45, 0.55, 0.7, and 0.8.arrow_forward

- Two materials, A and B, are to be separated using two unit operations, 1 and 2. The feed has 10 tons/h A and 4 tons/h B. The split (fraction of material rejected by each operation) is given in Table P5-14. a. Which sequence of operations, (l?2) or (2?1), will yield the greatest recovery of material A? b. What will be the purity of material A using that sequence? c. What will be the efficiency of separation for the entire process train with regard to material A using the Worrell-Stesed equation?arrow_forwardRefer to Problem 2.C.1. Results of the sieve analysis for Soils A, B, and C are given below. To obtain a more representative sample for further geotechnical testing, a ternary blend is created by uniformly mixing 8000 kg of each soil. Answer the following questions. a. If a sieve analysis is conducted on the mixture using the same set of sieves as shown above, compute the mass retained (as a percentage) and cumulative percent passing in each sieve. b. What would be the uniformity coefficient (Cu) and the coefficient of gradation (Cc) of the mixture?arrow_forward

arrow_back_ios

arrow_forward_ios

Recommended textbooks for you

Solid Waste EngineeringCivil EngineeringISBN:9781305635203Author:Worrell, William A.Publisher:Cengage Learning,

Solid Waste EngineeringCivil EngineeringISBN:9781305635203Author:Worrell, William A.Publisher:Cengage Learning, Fundamentals of Geotechnical Engineering (MindTap...Civil EngineeringISBN:9781305635180Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning

Fundamentals of Geotechnical Engineering (MindTap...Civil EngineeringISBN:9781305635180Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning Principles of Geotechnical Engineering (MindTap C...Civil EngineeringISBN:9781305970939Author:Braja M. Das, Khaled SobhanPublisher:Cengage Learning

Principles of Geotechnical Engineering (MindTap C...Civil EngineeringISBN:9781305970939Author:Braja M. Das, Khaled SobhanPublisher:Cengage Learning Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781305081550Author:Braja M. DasPublisher:Cengage Learning

Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781305081550Author:Braja M. DasPublisher:Cengage Learning Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781337705028Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning

Principles of Foundation Engineering (MindTap Cou...Civil EngineeringISBN:9781337705028Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning

Solid Waste Engineering

Civil Engineering

ISBN:9781305635203

Author:Worrell, William A.

Publisher:Cengage Learning,

Fundamentals of Geotechnical Engineering (MindTap...

Civil Engineering

ISBN:9781305635180

Author:Braja M. Das, Nagaratnam Sivakugan

Publisher:Cengage Learning

Principles of Geotechnical Engineering (MindTap C...

Civil Engineering

ISBN:9781305970939

Author:Braja M. Das, Khaled Sobhan

Publisher:Cengage Learning

Principles of Foundation Engineering (MindTap Cou...

Civil Engineering

ISBN:9781305081550

Author:Braja M. Das

Publisher:Cengage Learning

Principles of Foundation Engineering (MindTap Cou...

Civil Engineering

ISBN:9781337705028

Author:Braja M. Das, Nagaratnam Sivakugan

Publisher:Cengage Learning