Cornerstones of Cost Management (Cornerstones Series)

4th Edition

ISBN: 9781305970663

Author: Don R. Hansen, Maryanne M. Mowen

Publisher: Cengage Learning

expand_more

expand_more

format_list_bulleted

Question

What is this company's manufacturing cycle efficiency

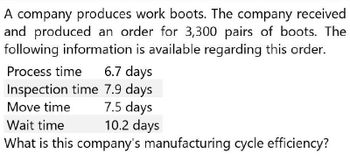

Transcribed Image Text:A company produces work boots. The company received

and produced an order for 3,300 pairs of boots. The

following information is available regarding this order.

6.7 days

Process time

Inspection time 7.9 days

Move time

Wait time

7.5 days

10.2 days

What is this company's manufacturing cycle efficiency?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by stepSolved in 2 steps

Knowledge Booster

Similar questions

- Expert Need your advicearrow_forwardNavern Corporation manufactures and sells custom home elevators. From the time an order is placed until the time the elevator is installed in the customer's home averages 82 days. This 82 days is spent as follows: Wait time Inspection time Process time Move time Queue time What is Navern's manufacturing cycle efficiency (MCE) for its elevators? Multiple Choice 41.5% 33.3% 58.5% 16 days 12 days 22 days 21 days 11 days 54.9%arrow_forwardA company manufactures hiking shoes.... Please answer the general accounting questionarrow_forward

- Navern Coporation manufactures and sells custom home elevators. From the time an order is placed until the time the elevator is installed in the customer's home averages 44 days. This 44 days is spent as follows: Wait time 12 days Inspection time Process time Move time Queue time 12 days 5 days 6 days 9 days What is Navern's manufacturing cycle efficiency (MCE) for its elevators? Multiple Cholce 38.6% 15.6% 61.4% 591% 65°F Cloudy search DELLarrow_forwardNeed answer the accounting questionarrow_forwardIf Toyota Motor Company receives an order on May 1, begins production on May 19, and ships the order on May 24 immediately following production, then what is the manufacturing cycle efficiency (MCE) ratio? (Enter your answer as a whole number.) Manufacturing cycle efficiency (MCE)atio %arrow_forward

- Schlarbaum Corporation's management keeps track of the time it takes to process orders. During the most recent month, the following average times were recorded per order: Days Wait time 13.2 Inspection time 0.7 Process time 1.6 Move time 0.6 Queue time 2.2 Required: a. Compute the throughput time. (Round your answer to 1 decimal places.) b. Compute the manufacturing cycle efficiency (MCE). (Do not round intermediate calculations. Round your answer to nearest whole percentage.) c. What percentage of the production time is spent in non-value-added activities? (Do not round intermediate calculations. Round your answer to nearest whole percentage.) d. Compute the delivery cycle time. (Round your answer to 1 decimal place.)arrow_forwardEyring Manufacturing produces a component used in its production of washing machines. The time to set up and produce a batch of the components is two days. The average daily usage is 800 components, and the maximum daily usage is 875 components. Required: Compute the reorder point assuming that safety stock is carried by Eyring Manufacturing. How much safety stock is carried by Eyring?arrow_forwardCompute (a) cycle time, (b) value-added time, (c) non-value-added time, and (d) cycle efficiency using the following information for a manufacturer. Process time. 2.10 days Move time. 0.75 days Inspection time. 0.50 days Wait time. 0.15 daysarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning

Cornerstones of Cost Management (Cornerstones Ser...

Accounting

ISBN:9781305970663

Author:Don R. Hansen, Maryanne M. Mowen

Publisher:Cengage Learning