Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

Transcribed Image Text:7:12

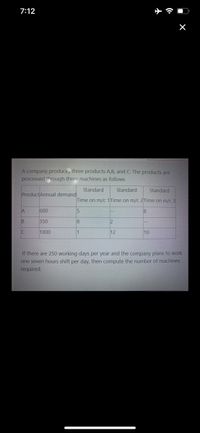

A company produces three products A,B, and C. The products are

processed through three machines as follows

Standard

Standard

Standard

ProductAnnual demand

Time on m/c 1Time on m/c 2Time on m/c 3

A

600

350

8

2

1000

1

12

10

If there are 250 working days per year and the company plans to work

one seven hours shift per day, then compute the number of machines

required.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 2 steps with 2 images

Knowledge Booster

Similar questions

- Kingcade Corporation keeps careful track of the time required to fill orders. Data concerning a particular order appear below: Wait time Process time Inspection time Move time Queue time The throughput time was: Multiple Choice 33.1 hours 4.7 hours 28.4 hours 14.3 hours Hours 18.8 1.6 0.6 2.5 9.6arrow_forward9. The Ace Manufacturing Company has orders for three similar products: Orders Product (units) A 2000 500 1200 B C Three machines are available for the manufacturing operations. All three machines can produce all the products at the same production rate. However, due to varying defect per- centages of each product on each machine, the unit costs of the products vary depending on the machine used. Machine capacities for the next week and the unit costs are as follows: Сараcity (units) Product Machine Machine A в C 1500 $1.00 $1.30 $1.10 $1.20 $1.40 $1.00 $0.90 $1.20 $1.20 1 1500 1000 3 Use the transportation model to develop the minimum cost production schedule for the products and machines. Show the linear programming formulation. 123arrow_forwardA toy firm produces drums sequentially on three machines- A, B, and C- with cycle times of three, four, and six minutes, respectively. a) Determine the optimum efficiency and output rates for adding one, two... six more machines b) Assume now that two identical lines are operating, each with machines A, B, and C. If new machines can be shared between the lines, how should one, two, and then three new machines be added? What are the resulting efficiencies and outputs of the two lines? Is it always best to equally share extra machines between the two lines?arrow_forward

- Use the following information to answer question 8-10. A company keeps track of the time required to fill orders carefully. The following data are presented: Hours Move time 2.6 Queue time Inspection time Delivery cycle time 0.4 15 Manufacturing cycle efficiency of the company is 0.12. The process time should be: A. 1.5 hours. B. 2.5 hours. C. 1.2 hours. 8. D. 0.5 hours. E. 3 hours. 9. The wait time should be: A. 1.5 hours. B. 2.5 hours. C. 1.2 hours. D. 0.5 hours. E. 3 hours. 10. Which of the following can increase the manufacturing cycle efficiency of the company, while other things remain unchanged? A. Decrease the wait time. B. Increase the queue time. C. Decrease the move time. D. Decrease the process time. E. Increase the wait time.arrow_forwardOrder 1 2 3 4 5 Time Since Order Arrived (hours ago) 3 1 0 6 5 You answered Sequence Order The due dates reflect the need for the order to be at its next operation. Develop separate schedules by using the FCFS and EDD rules. Compare the schedules on the basis of average flow time and average past due hours. Using the FCFS (first come, first served) decision rule for sequencing the orders, the order is Sequence Order Estimated Machine Time (hours) 15 9 7 10 3 1 5 Rule EDO FCFS 4 4 Using the EDD (earliest due date) decision rule for sequencing the orders, the order is (to resolve a tie, use order in which the orders were received) ¹2 1 4 2 3 Due Date (hours from now) 5 5 3 18 20 21 12 The average flow time and average past due hours for each option (enter your responses are real numbers rounded to two decimal place Average Flow Time Average Past Due Hoursarrow_forwardWhy is the Hayes and Wheelwright product-process matrix NOT used to analyze service delivery systems? a. The relationship between volume and process is not found in many service businesses. b. Services tend to have lower variety, so the variety element of Hayes & Wheelwright is not applicable. c. Services cannot add capacity. d. When services change processes to increase volume, they can still handle a wide variety of customer requests.arrow_forward

- A process has six resources and three types of flow units. How many rows will there bein the demand matrix?a. 2b. 3c. 6d. 18arrow_forwardAt Fraser engineering. Erix is trying to decide whether to purchase a certain part to to have it produced internally. Internal production could use either of two processes. One would entail a variable cost per unit of $17, and an annual fixed cost of $240,000. Three vendors are willing to provide the part. Vendor A has a price of $20 per-unit for any volume up to 30,000 units Vendor B has a price of $22 per-unit for demand of 1,000 units or less, and $18 per-unit for larger quantities. Vendor C offers a price of $21 per-unit for the first 1,000 units, and $19 for each additional unit. What is the correct formula to use to compare these options? Which options would be best for: I. 10,000 units? ii. 20,000 units? iii. 100,000 units? What is the value in considering these options across three very different demand values ranging from 10,000 to 100,000 units?arrow_forwardThe process through which inputs are converted into outputs is referred to as: a. Transformation process. b. Materials handling process c. Servicing process. d. Maintenance process.arrow_forward

- DreamInflate is a balloon manufacturing company. Balloon manufacturing consists of seven work stations, each performing a single step as indicated in the table below. There are five workers manned for the seven work stations as shown. Assume the workers are paid $15 per Worker Task Sequence Processing Time (secs/balloon) Task Dye production Electrocharging Dipping (Cold and Hot) Mortar Dipping Balloon inflation and delaltexing Vulcanization Inspection/Testing 1 30 w1 20 3 35 W2 25 W3 30 W4 6. 45 W5 7 40 hour. Each balloon pack is sold for $6 and has a variable cost of $1. The company has fixed costs of $200 per hour. There is more demand than the overall production system can provide. Based on the information provided, answer the following questions: • What is the cost of direct labor for balloons? • How much profit does DreamInflate make every hour? (note that the cost of direct labor is also a variable cost). What would the profit of DreamInflate be if the variable costs were 10…arrow_forwardEsplanade Marine Parts Inc. wants to produce parts in batches of 60 parts. Each part must be processed sequentially from workstation A to B. Processing Workstation Batch Size (Q) Time per Part 40 seconds A B 60 60 15 seconds a. How many seconds are required to produce the batch under the assumptions of batch processing? Round your answer to the nearest whole number. seconds b. How many seconds are required to produce the batch under the assumptions of single-piece flow processing? Round your answer to the nearest whole number. seconds C. Compare the two solutions in terms of time saved. Round your answer to the nearest whole number. Using the assumptions of -Select- processing saves seconds.arrow_forwardI need the answer for part carrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.