Practical Management Science

6th Edition

ISBN: 9781337406659

Author: WINSTON, Wayne L.

Publisher: Cengage,

expand_more

expand_more

format_list_bulleted

Question

thumb_up100%

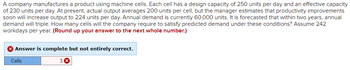

Transcribed Image Text:A company manufactures a product using machine cells. Each cell has a design capacity of 250 units per day and an effective capacity

of 230 units per day. At present, actual output averages 200 units per cell, but the manager estimates that productivity improvements

soon will increase output to 224 units per day. Annual demand is currently 60,000 units. It is forecasted that within two years, annual

demand will triple. How many cells will the company require to satisfy predicted demand under these conditions? Assume 242

workdays per year. (Round up your answer to the next whole number.)

Answer is complete but not entirely correct.

3

Cells

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution

Trending nowThis is a popular solution!

Step by stepSolved in 3 steps

Knowledge Booster

Similar questions

- A recurring maintenance job in a factory is being done by a three-man crew. Due to the nature of the job and space limitations, it was observed that two of the men were idle 37% of the time; one of the men was also idle an additional of the time, and at any given time only one man was required. The men were each paid P24.00 per hour. Each time the job was performed a set of tools and equipment with a value equivalent to P36.00 per hour was used. If the three-men crew could complete the work in 5 hours, which crew size would be the most economicalarrow_forwardA toy firm produces drums sequentially on three machines- A, B, and C- with cycle times of three, four, and six minutes, respectively. a) Determine the optimum efficiency and output rates for adding one, two... six more machines b) Assume now that two identical lines are operating, each with machines A, B, and C. If new machines can be shared between the lines, how should one, two, and then three new machines be added? What are the resulting efficiencies and outputs of the two lines? Is it always best to equally share extra machines between the two lines?arrow_forwardPrevost Chemicals manufactures an industrial solvent at its only processing plant. A liquid chemical and labor are the two primary inputs. All other resources are included in manufacturing overhead. The plant never has any work-in-process or finished goods inventories. Information from the previous four periods of production follows: Chemical input (gallons) Labor input (hours) Solvent sales (gallons) Average price of chemical per gallon Average wage rate per hour Average sales price per gallon Manufacturing overhead (total) Required A Required B Required C Required: a. Compute the partial productivity measures for chemical for the four periods. b. Compute the partial productivity measures for labor for the four periods. c. Compute the total factor productivity for the four periods. Complete this question by entering your answers in the tabs below. Period Period 1 125,000 12,500 110,000 Period 1 $ 2.00 28.00 10.26 236,000 Compute the partial productivity measures for chemical for the…arrow_forward

- Sniparrow_forwardDeja Brew, Inc., produces and sells 1,000 pallets of tea. Selling price per pallet: $700 Variable cost per pallet: $100 Annual fixed costs: $20,000 How many units would Deja Brew, Inc., need to sell to make $10,000? Round to the nearest whole pallet.arrow_forwardA loan processing operation at a local bank processes an average of 7 loans per day. The operation has a design capacity of 10 loans per day and an effective capacity of 8 loans per day. What is the utilization of the processing operation? Select one: a. 100.0% b. 87.5% c. 70.0% d. 80.0% Warranty expense, the cost that a business incurs for the repair or replacement of goods that has sold, is an example of which of the following? Select one: a. Internal failure cost b. Appraisal cost c. Prevention cost d. External failure costarrow_forward

- Answer format: Number: Round to: 2 decimal places.arrow_forwardHow many workers are needed at each stage if management wants a utilization of at least 85 percent? Round your answers up to the nearest whole number. Stage A: __ workers Stage B: __ workers Stage C: __ workers Stage D: __ workers Stage E: __ workers Suppose that the number of workers at each stage are as follows: Stage Number of Workers A 5 B 3 C 7 D 5 E 2 What is the output rate at each stage? Round your answers to the nearest whole number. Stage A: __ units/hour Stage B: __ units/hour Stage C: __ units/hour Stage D: __ units/hour Stage E: __ units/hour Where is the bottleneck in this process? The bottleneck is (Stage A, B, C, D, or E).arrow_forwardKnott's Industries manufactures standard and super premium backyard swing sets. Currently it has four identical swing-set-making machines, which are operated 275 days per year and 8 hours each day. A capacity cushion of 20 percent is desired. The following information is also known Annual Demand Standard Processing Time Average Lot Size Standard Setup Time per Lot a. Does Knott's have sufficient capacity to meet annual demand? Knott's does Standard Model 20,000 5min 50 30 min Super Premium Model 10,000 17 min 30 45 min have sufficient capacity to meet annual demand because 3 machines are needed. (Enter your response rounded up to the next whole number.) b. If Knott's was able to reduce the setup time for the Super Premium Model from 45 minutes to 30 minutes, would there be enough current capacity to produce 20,000 units of each type of swing set? If Knott's was able to reduce the setup time for the Super Premium Model from 45 minutes to 30 minutes, there would not be enough capacity to…arrow_forward

- Knott's Berry Farm is contemplating buying a new van for its operations. The farm's engineering staff has researched the market and found 2 units that appear to meet their requirements. Truck # 1 has a cost of $37,000 and requires an annual maintenance cost of $2,700. At the end of its useful life (3 years), it is projected to have a salvage value of $5,000. On the other hand, Truck #2 has an initial cost of $40,000 and requires only $2,000 in annual operating costs because the manufacturer is claiming that some routine maintenance is covered in the price of the truck. Truck # 2 has an estimated salvage value of $8,000 at the end of its 4 year service life. The CEO has determined that the farm's MARR is 12%. The trucks are needed for 12 years according to the 2024 Strategic Plan. The Engineering Department has determined that no significant changes are needed in the future that would change prices and functional characteristics of each truck. As a member of the Engineering Department,…arrow_forwardThe measure of production that considers historical and estimated future production levels and cyclical fluctuations is referred to as: Group of answer choices expected capacity normal capacity theoretical capacity practical capacityarrow_forwardSturgill Manufacturing Inc. needs to predict the numbers of machines and employees required to produce its planned production for the coming year. The plant runs three shifts continuously during the workweek, for a total of 120 hours of capacity per week. The shop efficiency (the percent of total time available for production), which accounts for setups, changeovers, and maintenance, averages 70% with a standard deviation of 5%, which reduces the weekly capacity. Six key parts are produced, and the plant has three different types of machines to produce each part. The machines are not interchangeable as they each have a specific function. The time to produce each part on each machine varies. The mean time and standard deviation (in hours) to produce each part on each machine are shown below: Mean Time Part Type Machine A Machine B Machine C 1 3.5 2.6 8.9 2 3.4 2.5 8 3 1.8 3.5 12.6 4 2.4 5.8 12.5 5 4.2 4.3 28 6…arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Operations Management

Operations Management

ISBN:9781259667473

Author:William J Stevenson

Publisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...

Operations Management

ISBN:9781259666100

Author:F. Robert Jacobs, Richard B Chase

Publisher:McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Production and Operations Analysis, Seventh Editi...

Operations Management

ISBN:9781478623069

Author:Steven Nahmias, Tava Lennon Olsen

Publisher:Waveland Press, Inc.